Assembly and operating instructions

General Instructions

Read these instructions carefully before

installation and use. Keep this manual for

future reference.

The guarantee is only valid if the units

are used in the manner intended by the

manufacturer and in accordance with the

Frico mounting and operating instructions.

Application area

The Thermozone AGI air curtain is supplied

with

ambient heat or water coil and is

intended to be installed above industrial- and

warehouse doors up to 6,0 meters height.

Protection class IP

.

Function

Air is drawn in at the rear of the unit and

blown out downwards so that it shields the

door opening and minimizes heat loss. To

achieve the optimum curtain effect the

unit must extend the full width of the door

opening.

The grille for directing exhaust air is

adjustable and is normally angled outwards to

achieve the best protection against incoming

cold air.

The efficiency of the air curtain depends

on the air temperature, pressure differences

across the doorway and any wind pressure.

NOTE! Negative pressure in the building

considerably reduces the efficiency of the air

curtain. The ventilation should therefore be

balanced.

Mounting

1.

Place the air curtain in the correct position.

2. Mark the holes and remove the air curtain.

3.

Drill holes into the floor and replace the air

curtain.

4

.

S

crew the

frame to the floor

.

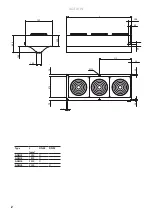

See fig. 1.

The unit is installed vertical or horisontal as

close to the door as possible.

For the protection of wider doorways, several

units can be mounted next to each other.

Ensure that the front panel/service hatch

is accessible and can be fully opened. For

minimum distance see fig. 2

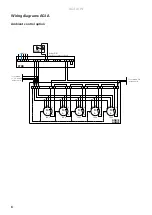

Electrical installation

The installation, which should be preceded by

an omnipolar switch with a contact separation

of at least 3 mm, should only be wired by a

competent electrician, in accordance with the

latest edition of IEE wiring regulations and in

accordance with this instructions.

The unit is

connected

to a connection box on the side of

the air curtain, below the pipe connections.

Water coil connection (AGI W)

The installation must be carried out by an

authorised installer. The water coil has copper

tubes with aluminium fins and is suitable for

connection to a closed water heating system.

The heating coil must not be connected to

a mains pressure water system or an open

water system.

Note that the unit should be preceded by a

regulating valve, see eg Frico valve assemblies.

The pipe

connections (

1

"

and 1 1/2"

,

internal thread)

are connected on the top side

of the unit.

The connections to the coil must be

equipped with shutdown valves to enable easy

disassembly.

Adjustment of air flow

The direction and speed of the air flow

should be adjusted considering the load on

the opening. Compressive forces affect the

air stream and make it bend inwards into the

premises (when the premises are heated and

the outdoor air is cold). The air stream should

therefore be directed outwards to withstand

the load. (Generally speaking, the higher the

load, the bigger the angle needed.)

Basic setting of fan speed

The fan speed when the door is open is set

using the speed control. Note that the air flow

direction and speed may need fine adjustment

depending on the loading of the door.

AGI A/W

19