13

920-087-04

A. Electrical Rating Tables

All 230/208 volt units are equipped with power cords. See Appendix A on page 21 for wiring in struc tions on 265V units.

NOTE: Use Copper Conductors ONLY. Wire sizes are per NEC, check local codes for over seas ap pli ca tions.

WIRE SIZE

Use ONLY wiring size recommended for

single outlet branch circuit.

FUSE/CIRCUIT

BREAKER

Use ONLY type and size fuse or HACR cir-

cuit breaker indicated on unit’s rating plate.

Proper current protection to the unit is the

responsibility of the owner. NOTE: A time

delay fuse is provided with 265V units.

GROUNDING

Unit MUST be grounded from branch circuit

through service cord to unit, or through sep-

arate ground wire provided on permanently

connected units. Be sure that branch circuit

or general purpose outlet is grounded. The

fi eld supplied outlet must match plug on

service cord and be within reach of service

cord. Refer to Table 1 for proper receptacle

and fuse type. Do NOT alter the service cord

or plug. Do NOT use an extension cord.

RECEPTACLE

The fi eld supplied outlet must match plug on

service cord and be within reach of service

cord. Refer to Table 1 for proper receptacle

and fuse type. Do NOT alter the service cord

or plug. Do NOT use an extension cord.

WIRE SIZING

Use recommended wire size given in Table

2 and install a single branch circuit. All wiring

must comply with local and national codes.

NOTE: Use copper conductors only.

B. Power Cord Information (230/208V models only)

All Friedrich 230/208V PTAC units are shipped from the factory with

a Leakage Current Detection Interrupter (LCDI) equipped power

cord. The LCDI device meets the UL and NEC requirements for

cord connected air conditioners effective August 2004.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET.

3. Press TEST (listen for click; Reset button trips and pops out).

4. Press and release RESET (listen for click; Reset button

latches and remains in). The power supply cord is ready for

operation.

ELECTRIC SHOCK HAZARD!

Turn off electric power before service or installation.

All electrical connections and wiring MUST be installed by a qualifi ed electrician and

conform to the National Electrical Code and all local codes which have jurisdiction.

Failure to do so can result in property damage, personal injury and/or death.

HACR – Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are hard wired.

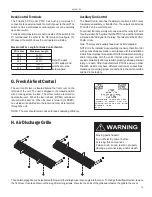

Table 1 250 V Re cep ta cles and Fuse Types

AMPS

15

20*

30

RECEPTACLE

TIME-DELAY TYPE FUSE

(or HACR circuit breaker)

15

20

30

AWG – American Wire Gauge

* Single circuit from main box

** Based on copper wire, single in su lat ed conductor at 60°C

Table 2 Recommended branch circuit wire sizes*

NAMEPLATE / MAXIMUM

CIRCUIT BREAKER SIZE

AWG WIRE SIZE**

15

20

30

14

12

10

NOTE: The LCDI device is not intended to be used as a switch.

Once plugged in the unit will operate normally without the need to

reset the LCDI device. If the LCDI device trips and requires resetting

the cause of the trip should be identifi ed prior to further use of the

PTAC.

If the device fails to trip when tested or if the power supply cord is

damaged it must be replaced with a new supply cord obtained from

the product manufacturer, and must not be repaired.

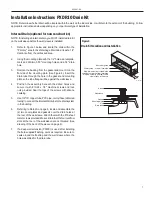

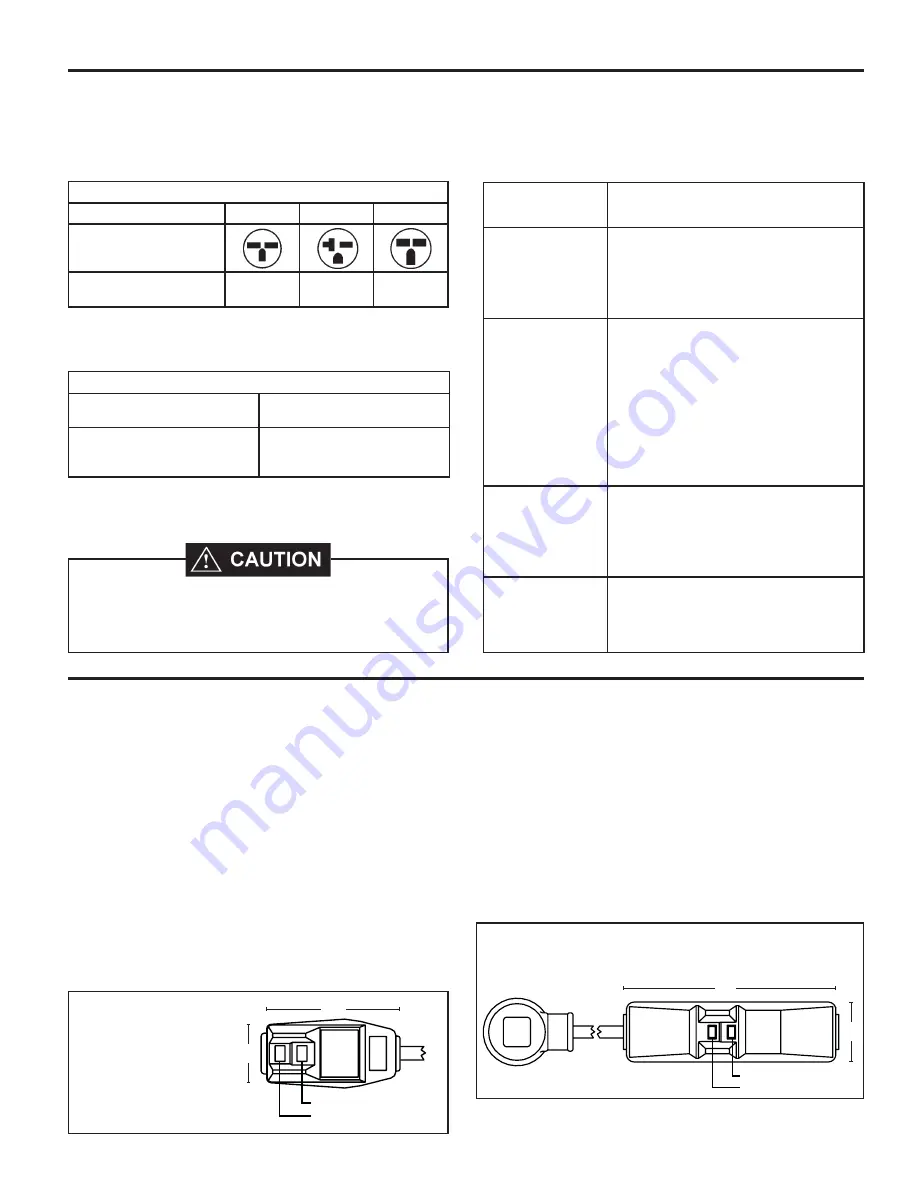

Figure 10b

30A LCDI Device

15/20A LCDI Device

Figure 10a

TEST

RESET

Test Button

Reset Button

2"

4.1"

Test Button

Reset Button

7"

2"