Specifications

subject to change.

Top Load Washer Specifications

•

Product Shipping Weight (approx.) – 183 Lbs.

•

An electrical supply with grounded three-prong receptacle is

required. The power supply circuit must be installed in accordance

with current edition of National Electrical Code (ANSI/NFPA 70) and

local codes & ordinances.

(Do not use same circuit as dryer.)

•

Voltage Rating – 120V / 60 Hz / 15 Amps

•

Amps @ 120 Volts = 4.0 Amps

•

Equipped with 120V 3-wire power supply cord, approx. 60" long.

•

Always consult local and national electric & plumbing codes.

•

To maximize detergent effectiveness, ambient temperature should

never be below 60° F.

•

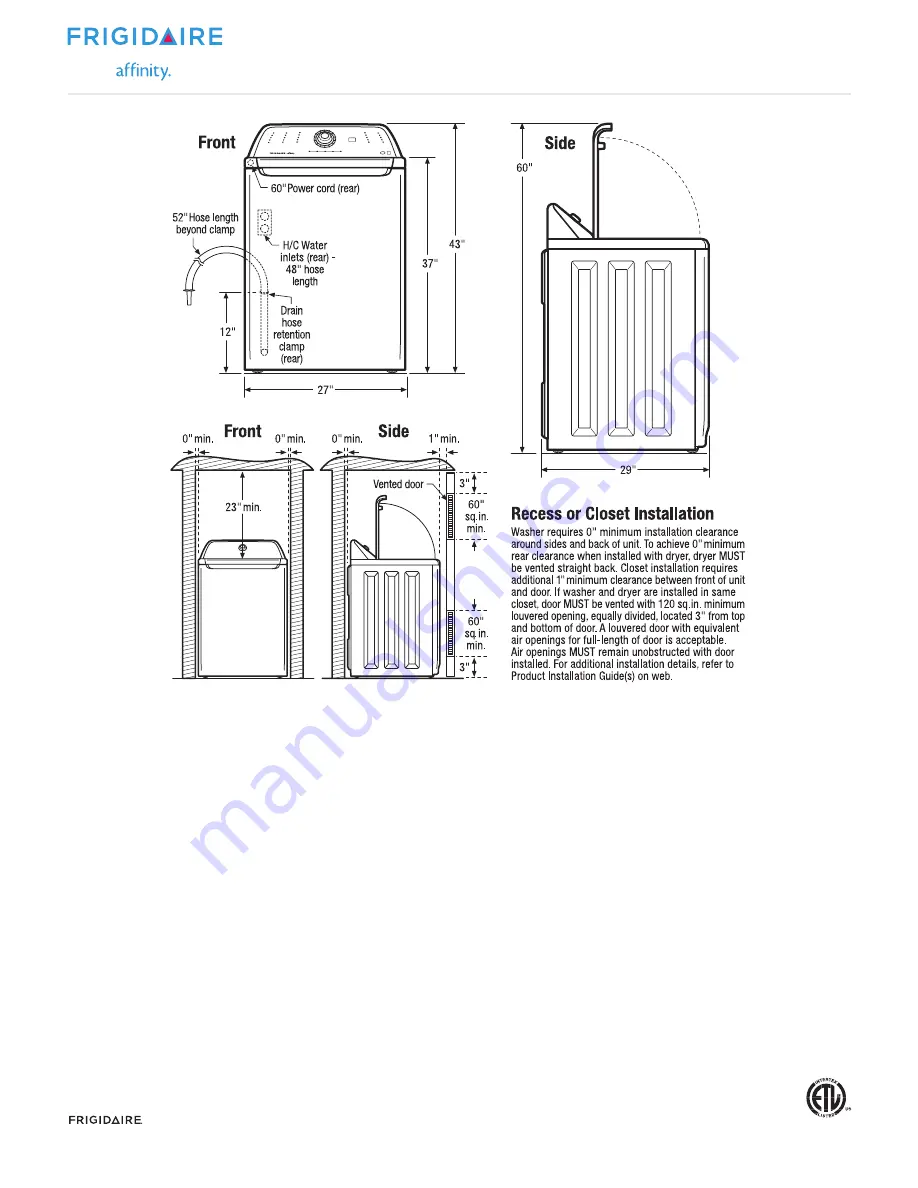

Washer can be installed in recess or closet requiring 0" minimum

installation clearance around sides and back of unit. To achieve

0" minimum rear clearance when installed with dryer, dryer MUST

be vented straight back. Closet installation requires additional 1"

minimum clearance between front of unit and door. If washer and

dryer are installed in same closet, door MUST be vented with 120 sq.

in. minimum louvered opening, equally divided, located 3" from top

and bottom of door. A louvered door with equivalent air openings

for full-length of door is acceptable. Air openings MUST remain

unobstructed with door installed.

(For additional installation details,

refer to Product Installation Guide on web.)

•

Do NOT install in area exposed to dripping water or outdoor weather

conditions; or where gasoline or other flammables, including

automobiles, are kept or stored.

•

Floor MUST be solid with 1" maximum slope. To minimize vibration

or movement, reinforcement of floor may be necessary. Do NOT

install on carpeted surface.

•

Leveling legs supplied to level unit properly and reduce excessive

noise and vibration.

•

H/C water faucets MUST be installed within 42" of washer’s water

inlet and MUST be 3/4" with threading for laundry hose connection

to connect to 48" inlet hoses.

•

Water pressure MUST be between 30 and 120 psi with NOT more

than 10 psi pressure difference between hot and cold.

•

Drain standpipe requires diameter of 1-1/4" min. and height of

33" min. / 96" max. above floor, capable of eliminating 17 gallons

per minute. Attached 52" drain hose can reach 74"-high standpipe.

For higher standpipe, optional Drain Hose Extension Kit available.

•

For manufactured or mobile home installation optional Mobile Home

Installation Kit (PN # 137067200) required.

(For specific installation

details, refer to Product Installation Guide on web.)

Note: For planning purposes only. Refer to Product Installation Guide

on the web at frigidaire.com for detailed instructions.

Optional Accessories

•

Mobile Home Installation Kit – (PN # 137067200).

•

Drain Hose Extension Kit – (PN # 137098000).

Top Load Washer

FAHE4044M W

3.4 Cu. Ft. D.O.E.

USA

•

10200 David Taylor Drive

•

Charlotte, NC 28262

•

1-800-FRIGIDAIRE

•

frigidaire.com

CANADA

•

5855 Terry Fox Way

•

Mississauga, ON L5V 3E4

•

1-800-265-8352

•

frigidaire.ca

FAHE4044M 06/12

© 2012 Electrolux Home Products, Inc.

Top Load Laundry - Washer

Frigidaire Affinity (M models)