8

30" DUAL FUEL SLIDE-IN RANGE INSTALLATION INSTRUCTIONS

(Models with an Electric Oven and a Gas Cooktop)

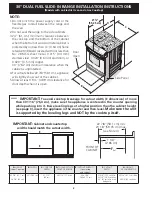

¾”

(1.9 cm)

¾”

(1.9 cm)

31½”

(81 cm)

Min.

Cutout

Width

Formed or tile countertop

trimmed ¾" (1.9 cm) back at

front corners of countertop

opening.

Figure 7

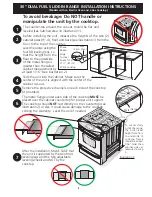

5

Cabinet Construction

To eliminate the risk of burns or fire by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet

storage space above range, reduce risk by installing a

range hood that projects horizontally a minimum of 5"

(12.7 cm) beyond the bottom of the cabinet.

Countertop Preparation

• The cooktop sides of the range fit over the cutout

edge of your countertop.

• If you have a

square finish (flat) countertop

, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

• Formed front-edged countertops

must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 7).

• Tile countertops

may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened (Figure 7).

6

Gas Supply – Installation

When shipped from the factory, this unit is designed

to operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and MUST

be connected in series with the gas supply line. To access

the regulator, remove the drawer.

For proper operation,

the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4"(10,16 cm) water

column (1.0 kPa) Natural gas manifold pressure; the inlet

pressure must be at least 5"(12.60 cm) water column

(1.25 kPa) Natural gas. For LP/Propane gas, the regulator

must be set for 10"(25,4 cm) water column (2.5 kPa)

manifold pressure; the inlet pressure must be at least

11"(27,9 cm) water column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 10). This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do not

block access to the shutoff valve. The valve is for turning

on or shutting off gas to the appliance. Open the shutoff

valve in the gas supply line. Wait a few minutes for gas

to move through the gas line.

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by A.G.A./

C.G.A.-approved flexible metallic union-connected

piping where local codes permit use.

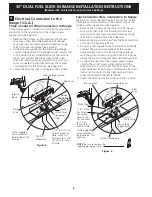

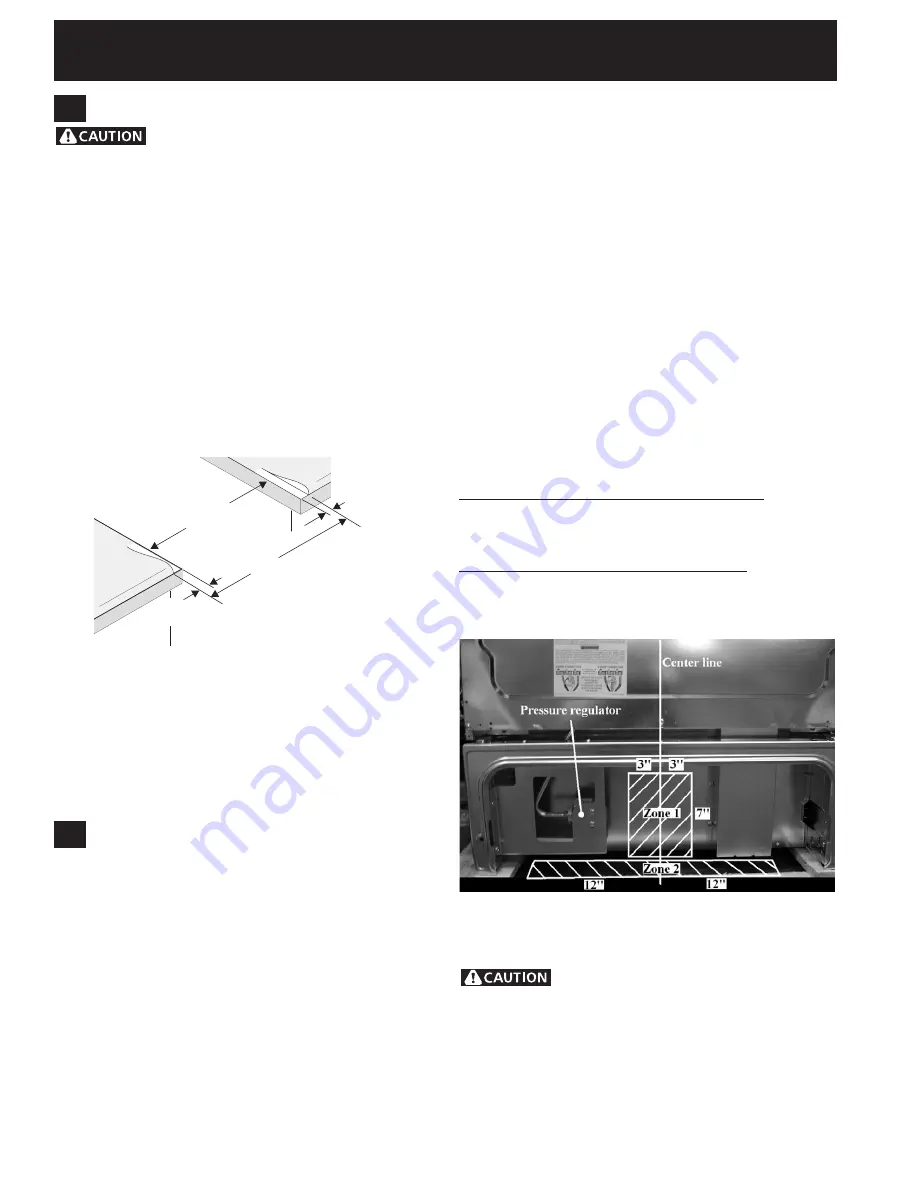

The gas supply piping can be through the back wall

(Figure 8, zone 1) or through the floor (Figure 8,

zone 2):

Zone 1 - Through the Back Wall (7" X 6")

- The best

place to have your gas line in is between 1" (2.5 cm) and

8" (20.3cm) from the floor and within 3" (7.6 cm) from

the center line.

Zone 2 - Through the Floor (~2" X 24")

- The gas line

can also come through the floor within 12" (30.5 cm)

from the center line against the back wall.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Figure 8

• If the existing cutout width is greater than

3 0 1 / 1 6 " ( 7 6 , 4 c m ) ,

re d u c e t h e ¾ " ( 1 . 9 c m )

dimension.

• Countertop must be level.

Place a level on the

countertop, first side to side, then front to back. If

the countertop is not level, the range will not be level.

The oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.