30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with Electric Ignition or Standing Pilot)

10

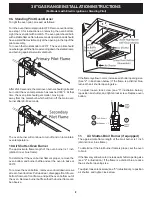

1c. Convert the Pressure Regulator - Non-Self-

Cleaning Standing Pilot Models

a.

Remove the cap from the pressure regulator.

b.

Remove the plunger from the cap.

c.

Turn the plunger with the enlarged end down for LP/

Propane use. Turn the plunger with the small end down for

Natural gas use. (See illustration below.)

d.

Replace the plunger inside the cap.

e.

Replace the cap.

f.

Remove the thermostat knob to access the selector key.

Check the selector key on the thermostat to be certain the

pointer is turned to select the proper fuel being used

(Natural or LP/Propane). Replace the thermostat knob.

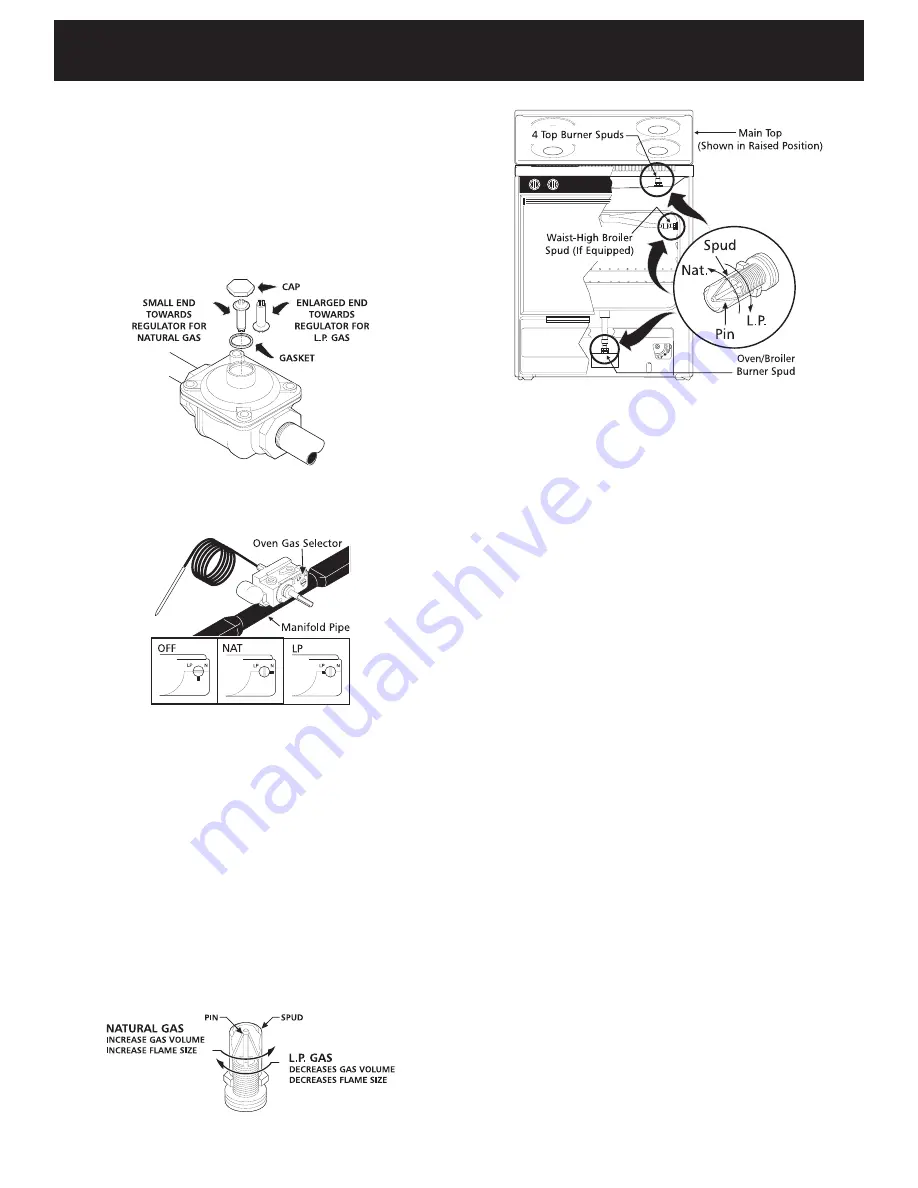

2. Convert Surface Burner Valves -All Models

a.

Lift and lock cooktop to gain access to the surface burner

spuds. Surface burner spuds for models with venturi

burners are located in the front of the burner box. For

models with dual or snap-in burners, the spuds are in the

bottom of the burner box.

b.

Using 1/2" wrench, adjust surface burner spud as follows.

For Natural to LP/Propane conversion tighten spud down

clockwise until snug (approximately 2-1/2 turns). This

restricts the flow of gas through the spuds to only that

allowed by the hollow LP/Propane metering pin. Do not

over tighten.

For LP/Propane to Natural conversion, loosen spuds

counter-clockwise (approximately 2-1/2 turns). This

increases the flow of gas around the metering pin.

3. Convert Oven Burner Spud

a.

Remove oven bottom and oven burner baffle located on

top of burner. To remove oven bottom, remove oven hold

down screws at rear of oven bottom. Pull up at rear,

disengage front to oven bottom from oven front-frame,

and pull the oven bottom straight out of the oven. Remove

nut attaching burner baffle to oven burner.

b.

Using 1/2" wrench, adjust oven burner spud as follows.

For Natural to LP/Propane conversion tighten spud down

clockwise until snug (approximately 2-1/2 turns). This

restricts the flow of gas through the spuds to only that

allowed by the hollow LP/Propane metering pin. Do not

over tighten.

For LP/Propane to Natural conversion, loosen spuds

counter-clockwise (approximately 2-1/2 turns). This

increases the flow of gas around the metering pin.

4. Convert Broil Burner Spud (if equipped)

a.

Using 1/2" wrench, adjust broil burner spud as follows. For

Natural to LP/Propane conversion tighten spud down

clockwise until snug (approximately 2-1/2 turns). This

restricts the flow of gas through the spuds to only that

allowed by the hollow LP/Propane metering pin. Do not

over tighten.

For LP/Propane to Natural conversion, loosen spuds

counter-clockwise (approximately 2-1/2 turns). This

increases the flow of gas around the metering pin.

After conversion is complete, follow normal instructions

on page 3 for installation and burner operation/

adjustments. For models with linear flow valves, the low

"simmer" setting must be adjusted after conversion.