30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with Electric Ignition or Standing Pilot)

8

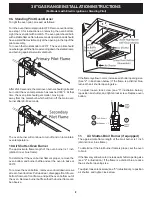

9b. Standing Pilot Oven Burner

To light the oven pilot, proceed as follows:

Turn the oven thermostat knob to OFF. Remove oven bottom,

see step 10 for instructions on removing the oven bottom.

Light the oven pilot with a match. The oven pilot should burn

with a stable flame after a few seconds operation and should

have a small flame visible only at the opening in the top of the

pilot assembly.

Turn oven thermostat knob to 300°F. The oven pilot should

now be larger with the flame extending down the slanted ramp

and burning against a small metal bulb.

After 20-40 seconds, the main oven burner should ignite and

burn until the oven temperature has reached 300°F. At that

time, the oven pilot should get smaller, moving up

away from the metal bulb which will turn off the main oven

burner after 20-40 seconds.

The oven burner will continue to turn off and on to maintain

oven temperature.

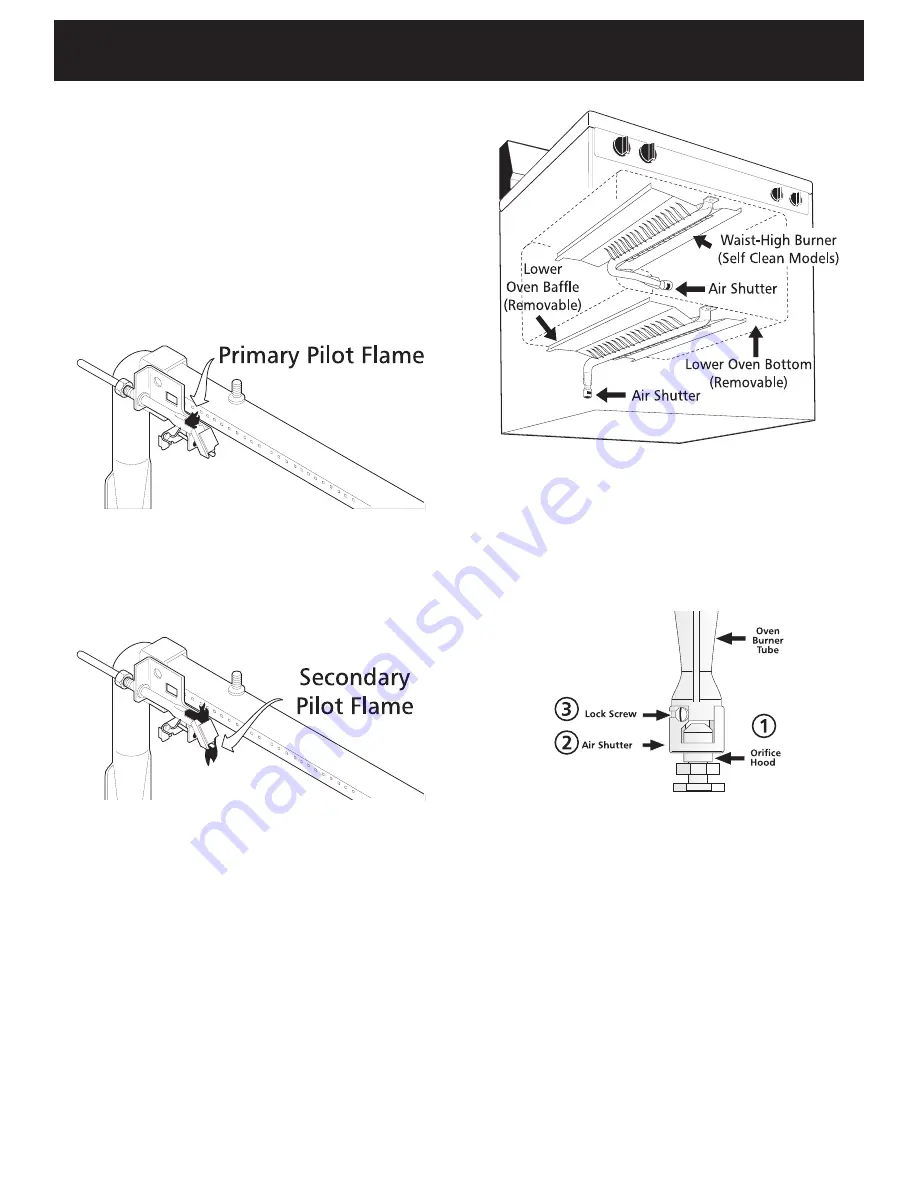

10. Air Shutter-Oven Burner

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine if the oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down screws

at rear of oven bottom. Pull up at rear, disengage front of oven

bottom from oven front frame, and pull the oven bottom out of

the oven. Remove burner baffle so that the burner flame can

be observe.

If the flame is yellow in color, increase air shutter opening size.

(See "2" in illustration below.) If the flame is a distinct blue,

reduce the air shutter opening size.

To adjust loosen lock screw (see "3" illustration below),

reposition air shutter, and tighten lock screw. Replace oven

bottom.

11.

Air Shutter-Broil Burner (if equipped)

The approximate flame length of the broil burner is 1 inch

(distinct inner, blue flame).

To determine if the broil burner flame is proper, set the oven

to broil.

If the flame is yellow in color, increase air shutter opening size

(see "2" in illustration.) If the flame is a distinct blue, reduce

the air shutter opening size.

To adjust, loosen lock screw (see "3" in illustration), reposition

air shutter, and tighten lock screw.