30" GAS RANGE INSTALLATION INSTRUCTIONS

(For Models with Electric Ignition or Standing Pilot)

9

12. Make Sure Range is Level.

Level the range by placing a level horizontally on an oven rack.

Check diagonally from front to back, then level the range by

either adjusting the leveling legs or by placing shims under the

corners of the range as needed.

13. After installation is complete, make sure all

controls are left in the OFF position.

Model and Serial Number Location

The serial plate is located under the lift-up cooktop.

When ordering parts for or making inquires about your range,

always be sure to include the model and serial numbers and

a lot number or letter from the serial plate on your range.

Your serial plate also tells you the rating of the burners, the

type of fuel and the pressure the range was adjusted for when

it left the factory.

Before You Call for Service

Check to make sure the house fuses or circuit breakers for

your range are not blown or open. Refer to the Avoid Service

Checklist and operating instructions in your Owner's Guide. It

may save you time and expense. The list includes common

occurrences that are not the result of defective workmanship

or materials in this appliance.

Refer to the warranty in your Owner's Guide for our

toll-free service number and address. Please call or write

if you have inquiries about your range product and/or

need to order parts.

Care, Cleaning and Maintenance

Refer to the Owner's Guide for operating and cleaning

instructions.

If removing the range is necessary for cleaning or maintenance,

shut off gas supply. Disconnect the gas and electrical supply.

If the gas or electrical supply is inaccessible, lift the unit

slightly at the front and pull out away from the wall. Pull only

as far as necessary to disconnect the gas and electrical

supply. Finish removing the unit for servicing and cleaning.

Reinstall in reverse order making sure to level the range and

check gas connections for leaks. See Anti-Tip Instructions for

proper anchoring instructions.

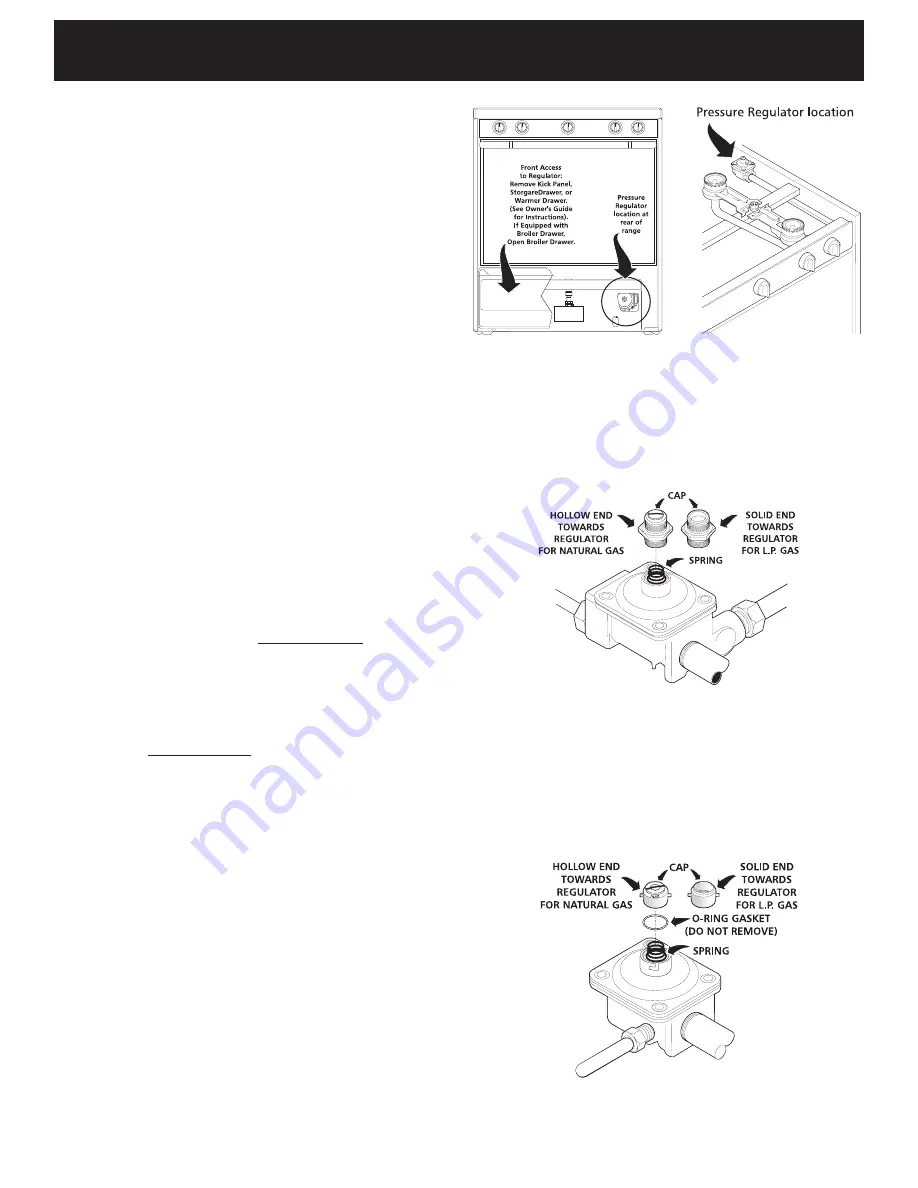

Gas Conversion

This range was adjusted for Natural or LP/Propane gas, as

specified on the serial plate.

Your regulator is in one of the two locations shown.

Do not remove the Pressure Regulator.

1a. Convert the Pressure Regulator

Self-Cleaning Electric Ignition Models

a.

Unscrew the cap from the pressure regulator. Be sure

spring stays in place.

b.

Turn the cap to the desired setting (see illustration below).

c.

Replace the cap of the regulator. The letters corresponding

with the type of gas being used should be visible on the

exposed end of the cap.

1b.Convert the Pressure Regulator

Non Self-Cleaning Electric Ignition Models

a.

Using a screwdriver or coin, turn the cap counterclockwise

to release from the pressure regulator. Be sure the O-ring

gasket stays in place.

b.

Turn the cap over and place into the slots. Turn clockwise

to lock in position. The letters corresponding with the type

of gas being used should be visible on the exposed end

of the cap.