12

CONNECTING WATER SUPPLY

WARNING

To avoid electric shock, which can cause death or severe personal injury, disconnect the

freezer from electrical power before connecting a water supply line to the freezer.

CAUTION

• Copper or Stainless Steel braided tubing is recommended for the water supply line. Water

supply tubing made of ¼ inch plastic is not recommended to be used. Plastic tubing greatly

increases the potential for water leaks, and the manufacturer will not be responsible for any

damage if plastic tubing is used for the supply line.

• DO NOT install water supply tubing in areas where temperatures fall below freezing.

• Chemicals from a malfunctioning softener can damage the ice maker. If the ice maker is

connected to soft water, ensure that the softener is maintained and working properly.

NOTE

Ensure that your water supply line connections comply with all local plumbing codes.

Before Installing The Water Supply Line, You Will Need:

•

Basic Tools: adjustable wrench, flat-blade screwdriver, and Phillips

TM

screwdriver.

• Access to a household cold water line with water pressure between 30 and 100 psi.

• A water supply line made of ¼ inch (6.4 mm) OD, copper or stainless steel tubing. To deter-

mine the length of tubing needed, measure the distance from the ice maker inlet valve at the

back of the freezer to your cold water pipe. Then add approximately 7 feet (2.1 meters), so

the freezer can be moved out for cleaning (as shown).

• A shutoff valve to connect the water supply line to your household water system. DO NOT use

a self-piercing type shutoff valve.

• A compression nut and ferrule (sleeve) for connecting a copper water supply line to the ice

maker inlet valve.

To Connect Water Supply Line To Ice Maker Inlet Valve:

1. Disconnect appliance from electric power source.

2.

Place end of water supply line into sink or bucket. Turn ON water supply and flush supply

line until water is clear. Turn OFF water supply at shutoff valve.

3. Remove plastic cap from water valve inlet and discard cap.

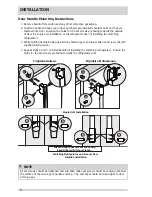

4. If you use

copper tubing

- Slide brass compression nut, then ferrule (sleeve) onto water

supply line. Push water supply line into water valve inlet as far as it will go (¼ inch / 6.4

mm). Slide ferrule (sleeve) into valve inlet and finger tighten compression nut onto valve.

Tighten another half turn with a wrench; DO NOT overtighten. See Figure A.

If you use

stainless steel tubing

- The nut and ferrule are already assembled on the

tubing. Slide compression nut onto valve inlet and finger tighten compression nut onto

valve. Tighten another half turn with a wrench; DO NOT overtighten. See Figure B.