PREPARE HOOD

1. Unpack hood and check contents. You should receive:

1 - assembled hood

1 - plastic bag, containing:

4 - 7/8” wood screws for mounting hood to cabinet

2 - 1/4” black sheet metal screws for mounting damper/

duct connector to hood

2 - aluminum filters

1 - damper/duct connector

For Ductfree Installations Only:

Discard damper/duct connector and two black sheet metal

screws.

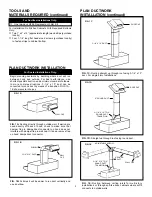

For Steps 2 - 6 below, refer to FIG. 2.

2. Set hood upside down and remove bottom cover and

screws.

3. Remove filters.

4. Remove wiring box cover and screws.

5. To make hood lighter and easier to handle, remove blower

assembly.

a.) Unplug blower.

b.) Loosen knurled nuts on mounting rods and slip rods

out of blower mounting brackets. Do not remove nuts

completely from rods.

c.) Lift out blower and set blower aside.

CAUTION

DO NOT GRASP BLOWER BY BLOWER WHEELS.

WHEELS MAY BE DAMAGED.

6. Remove light lens. Squeeze sides of lens toward center of

hood and lift lens out.

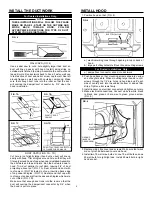

7. Remove either top or rear electrical knockout. (FIG. 3)

For Ducted Installations Only:

7. Remove either top or rear duct knockout. (FIG. 3)

Fasten damper/duct connector to hood over opening.

Use two black sheet metal screws provided in parts bag.

(FIG. 3)

3

FIG. 2

STEP 4

STEP 5

STEP 2

STEP 3

STEP 6

ELECTRICAL

KNOCKOUTS

VERTICAL DUCTING*

DUCT

KNOCKOUTS*

HORIZONTAL DUCTING*

HINGE

PINS

HINGE

PINS

* FOR DUCTED INSTALLATIONS ONLY.

FIG. 3