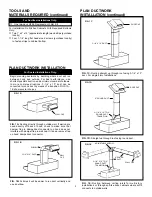

FIG. 6

INSTALL THE DUCTWORK

For Ducted Installations Only:

NOTE

THESE INSTRUCTIONS WILL FOLLOW THE PLANS

MADE ON PAGE 2. START ON THE OUTSIDE AND

WORK BACK TOWARD HOOD. FOLLOW

APPROPRIATE DIRECTIONS FOR TYPE OF DUCT

SYSTEM YOU ARE INSTALLING.

WALL CAPS (FIG. 6)

Use a saber saw to cut a hole slightly larger than duct so

duct will line up easily with hood. Install casing strips on

outside walls finished in siding. Assemble the ductwork and

tape all joints. Run ductwork back to hood. Fasten wall cap

to last section of duct and nail or screw cap to wall. Seal all

around flange on wall cap with caulking compound. Make

sure that enough duct runs into the room so that the duct

will overlap the damper/duct connector by 3/4” when the

hood is installed.

5

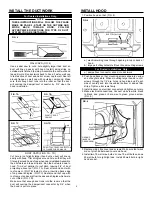

FIG. 7A

FIG. 7B

3/4"

PLASTIC ROOF

CEMENT

FIG. 7C

FIG. 7D

NAIL

ROOF CAPS (FIGS. 7A - 7D)

Cut hole in roof slightly larger than duct so duct will line up

easily with hood. Trim shingles around hole so that they will

fit snugly around hood of cap when cap is installed. Assemble

the ductwork and tape all joints. Run the ductwork down to

hood. Trim duct parallel to roof pitch, leaving 3/4” of duct

projecting above roof (FIG. 7A). Seal all around duct with

roof cement. (FIG 7B) Install roof cap, inserting back edge

of cap under shingles. (FIG 7C) Seal around roof cap with

roof cement and seal all nail heads and shingles which were

cut or lifted. (FIG. 7D)

Make sure that enough duct runs into the room so that the

duct will overlap the damper/duct connector by 3/4” when

the hood is put into place.

ELECTRICAL LINE

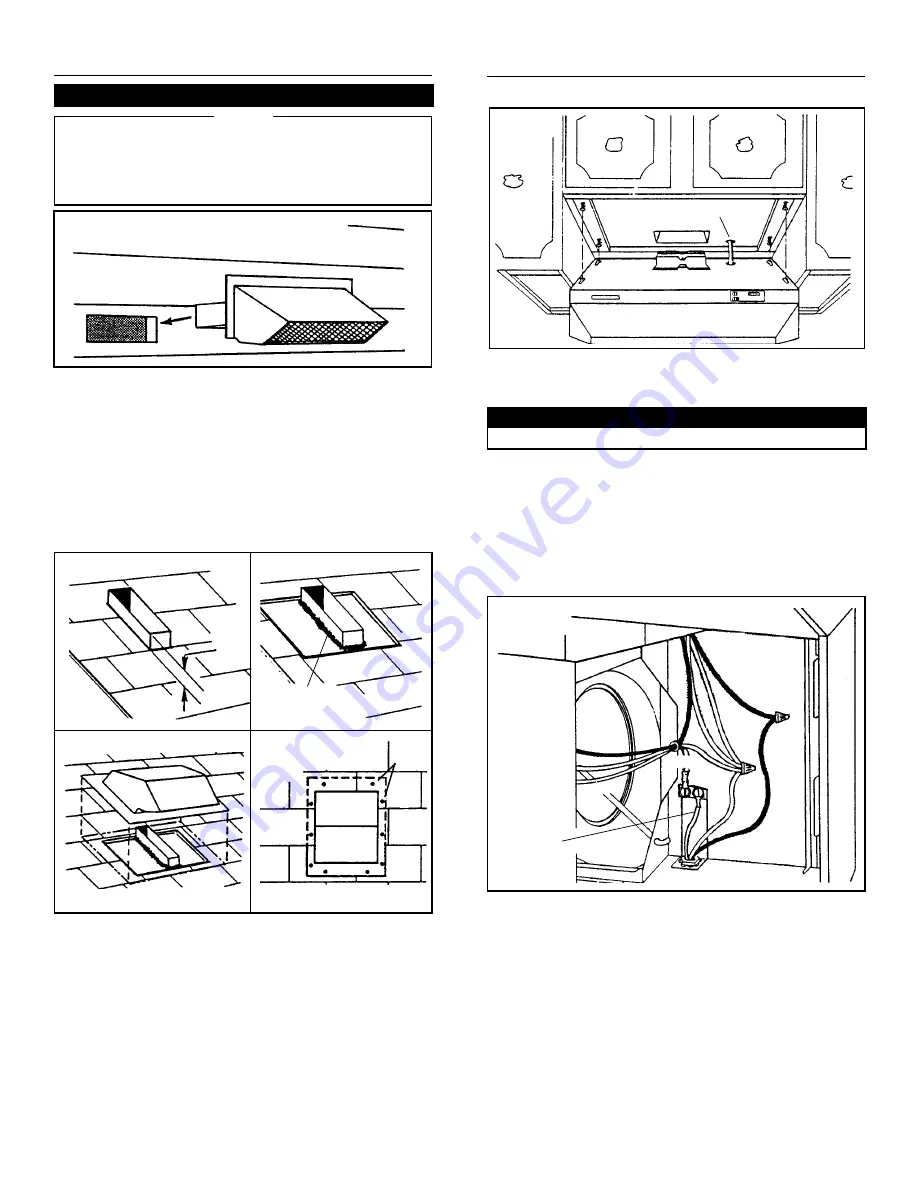

FIG. 8

INSTALL HOOD

1. Position hood so that: (FIG. 8)

a.) electrical wiring runs through opening in top or back of

hood.

b.) large part of keyhole slots fit over hood mounting screws

For Ducted Installations Only:

c.) damper/duct connector slides into ductwork.

2. Push hood back so that mounting screws slide into narrow

end of keyhole slots. When mounting larger hoods, run (2)

screws through the 1/4” dia. holes (in hood top and 8” each

side of center) and into the cabinet bottom or added filler

strips. Tighten all screws firmly.

3. Install locknut on electrical connector and tighten securely.

4. Make electrical connections. Connect white to white, black

to black, and green or bare wire to green ground screw.

(FIG. 9)

5. Replace wiring box cover and screws. Make sure that wires

are not pinched between cover and hood.

6. Install two 75 watt max. bulbs, or one 75 watt bulb and one

25 watt bulb for night-light use. Install 25 watt bulb in right-

hand socket.

FIG. 9

GROUND

(BARE OR

GREEN WIRE)

BLACK

BLACK

BLACK

WHITE

WHITE

GREEN

GREEN

WHITE

BLACK

WHITE

DO NOT CAULK AROUND BOTTOM

OF FLANGE FOR DRAINAGE