17

7425MUM661

Model: CWB FC

- Use and Maintenance Manual

Rev02

5

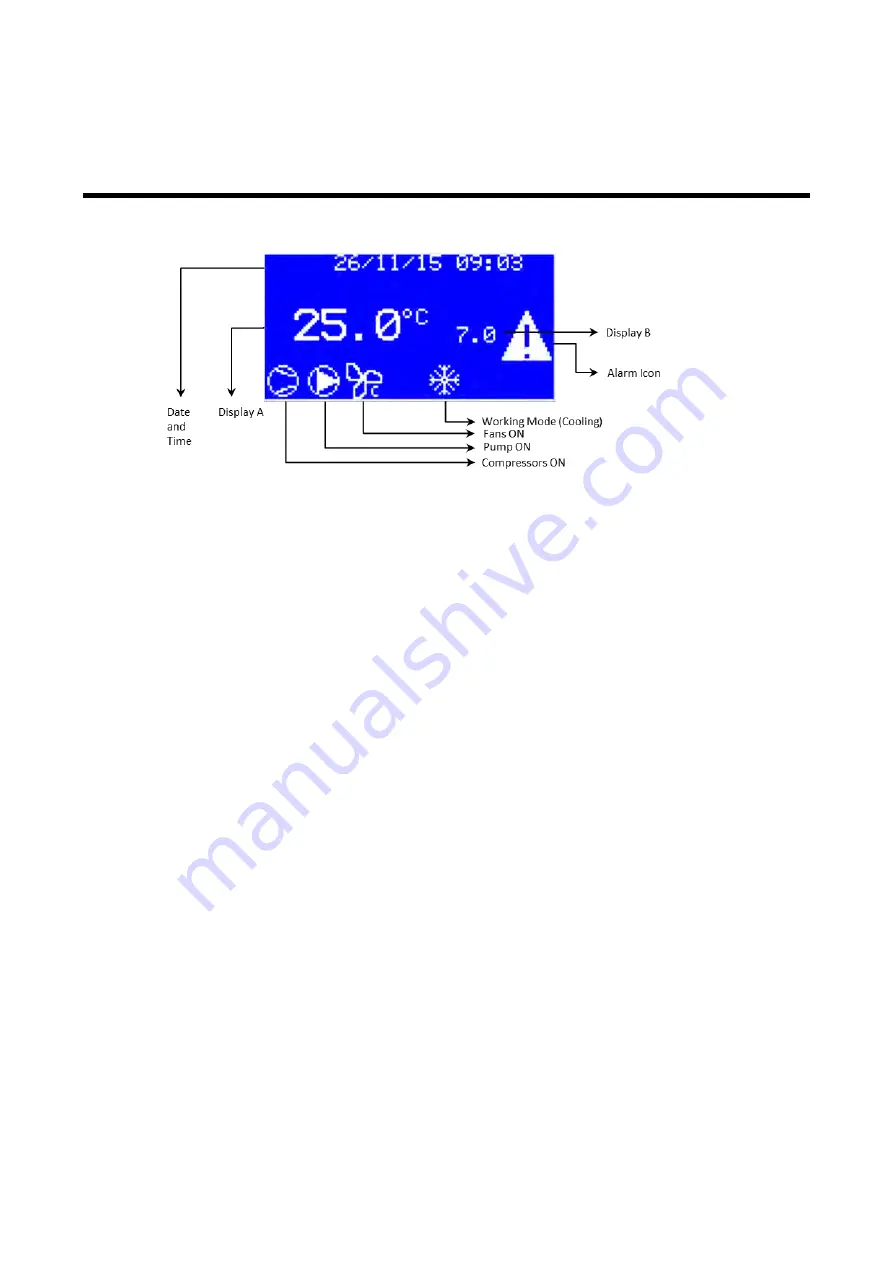

ELECTRONIC CONTROLLER

The electronic controller shows a series of icons representing chillers main components:

Electronic controller

It manages:

•

The functioning of the compressors to ensure that the water produced has a constant

temperature;

•

The speed of the fans;

•

The functioning of the pump;

•

The prevention of the high-pressure alarm.

Displays:

•

The state of the unit;

•

The state of the compressors;

•

The state of the fans;

•

The state of the pump;

•

The temperature set point (standard factory setting) (display B);

•

The temperature of the water produced (standard factory setting) (display A);

•

All digital and analogue inputs and outputs (parameters navigation);

•

All the alarms that can occur.