4

7425MUM651

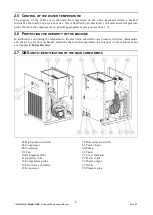

Model: QBS

- Use and Maintenance Manual

Rev. 02

2

O

PERATION

A

ND

M

AIN

C

OMPONENTS

2.1

R

EFRIGERANT CIRCUIT

QBS chillers use a vapour-compression cycle in a refrigerant circuit that essentially consists of the

following components: evaporator, compressor, condenser, lamination device (capillary tube).

Evaporator:

heat exchanger (tube and fins) to enable heat exchange between the water and the

refrigerant liquid without them coming into contact with each other. The water is cooled when it

passes through the evaporator.

Compressor:

compresses the steam from the evaporator to send it to the condenser at a higher

pressure.

Condenser:

tube and fins exchanger to enable heat exchange between the refrigerant and the air; it

creates refrigerant gas condensation transferring the gas refrigerant condensation heat to the air

(which flows externally); high pressure refrigerant liquid is thus produced.

Lamination device:

reduces the pressure of the liquid refrigerant coming from the condenser, which

is then sent to the evaporator.

Thanks to these components,

the vapour-compression cycle

works as follows: the refrigerant liquid

evaporates in the evaporator, chilling the water; the refrigerant vapours are then aspirated from the

compressor, which compresses them and sends them to the condenser under high pressure; here,

thanks to a flow of forced air from the fans, the high-pressure refrigerant gas is cooled, making it

condensed and undercooled.

The flow of refrigerant liquid then passes through the lamination valve (thermostatic expansion

valve), which drastically reduces its pressure: the refrigerant liquid returns to the evaporator at a

reduced pressure where it again evaporates, taking heat from the water.

The refrigerant circuit also includes a

water pump

, which ensures the flow of water to be chilled by

evaporation, and the

fan

which ensures the condenser is cooled.

2.2

W

ATER CIRCUIT

The water circuit mainly consists of a pump, evaporator, tank.

The water flows into the evaporator first where it is cooled, then into the tank, and is then suctioned

by the pump which sends it to the system (see

Water diagram

section 11).

All QBS units have an open circuit with a tank at atmospheric pressure.

See chapter

11 Water diagram

.

2.3

F

AN

The fan forces air through the condenser fins to remove the refrigerant gas condensation heat,

therefore limiting the pressure inside the condenser.

QBS chillers are equipped with axial fans and have internal heat protection for the motor windings.

2.4

C

ONDENSATION CONTROL

When the ambient air temperature decreases, air flow cooling capacity increases slightly, causing a

reduction in pressure inside the condenser; to limit this decrease in condensation pressure from falling

below acceptable limits for good cooling circuit operation the fan stops temporarily.