15

P359mane.fm

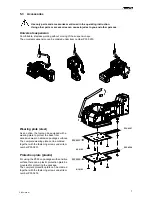

Assembly advise

• When inserting the piston pay attention to the proper seat of the piston in the thrust piece.

• Pay attention to the fitting position of the cutter (see drawing).

• Safe the screws N11.1115 with Loctite 222.

• Lubricate the rocker and the bolt P35.4210 in the area of the welding jaw with Klüber Isoflex NBU 15.

• Lubricate the balls, ball cage and the running surface of the balls on the welding gripper with Klüber Isoflex

Alltime SL2.

• Lubricate the cutter and the driver with Mobilux EP2.

9.3

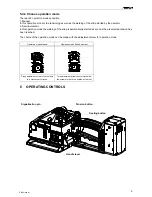

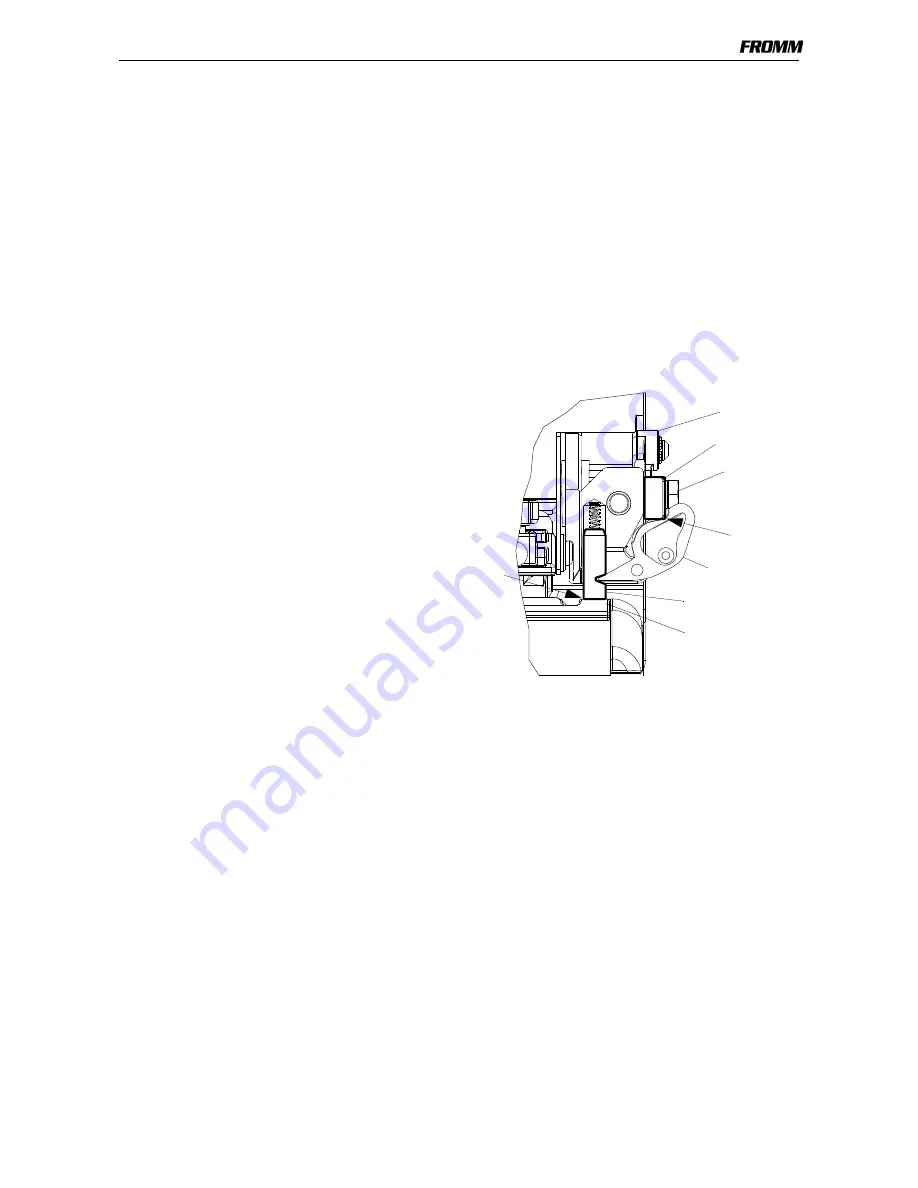

Adjustment of the coupler P35.0227

The coupler is adjusted in our works.

In case of replacing the seesaw lever, the coupler or the lever body, the coupler has to be readjusted.

Procedure as follows:

The tool is disconnected from the air supply.

The coupler is fitted into the tool.

• Loosen screw N1.1553.

• Displace thrust piece, so that it touches the two

seesaw levers without moving them.

• Retighten screw N1.1553.

Control:

The thrust piece must touch the seesaw levers (X1).

Both guide pins must sit on the welding stop

gripper(X2).

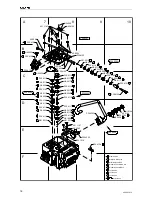

10 MAINTENANCE

Depending on the working conditions and the use of the tool the following maintenance has to be made

periodically:

10.1 Air unit

• Checking the air-pressure daily (never exceed 6 bar / 87psi)

• Checking oil-level daily

• The water separator must be emptied before it is full (unless automatic)

• The filter has to be cleaned following the instructions of the manufacturer of the air- unit

• Check the function and proper adjustment of the lubricator daily (approximately 1-2 drops/min.)

Coupler

Thrust piece

N1.1553

Seesaw lever

Welding stop

X1

X2

Guide pin

gripper