8

P359mane.fm

5.4

Adjustments

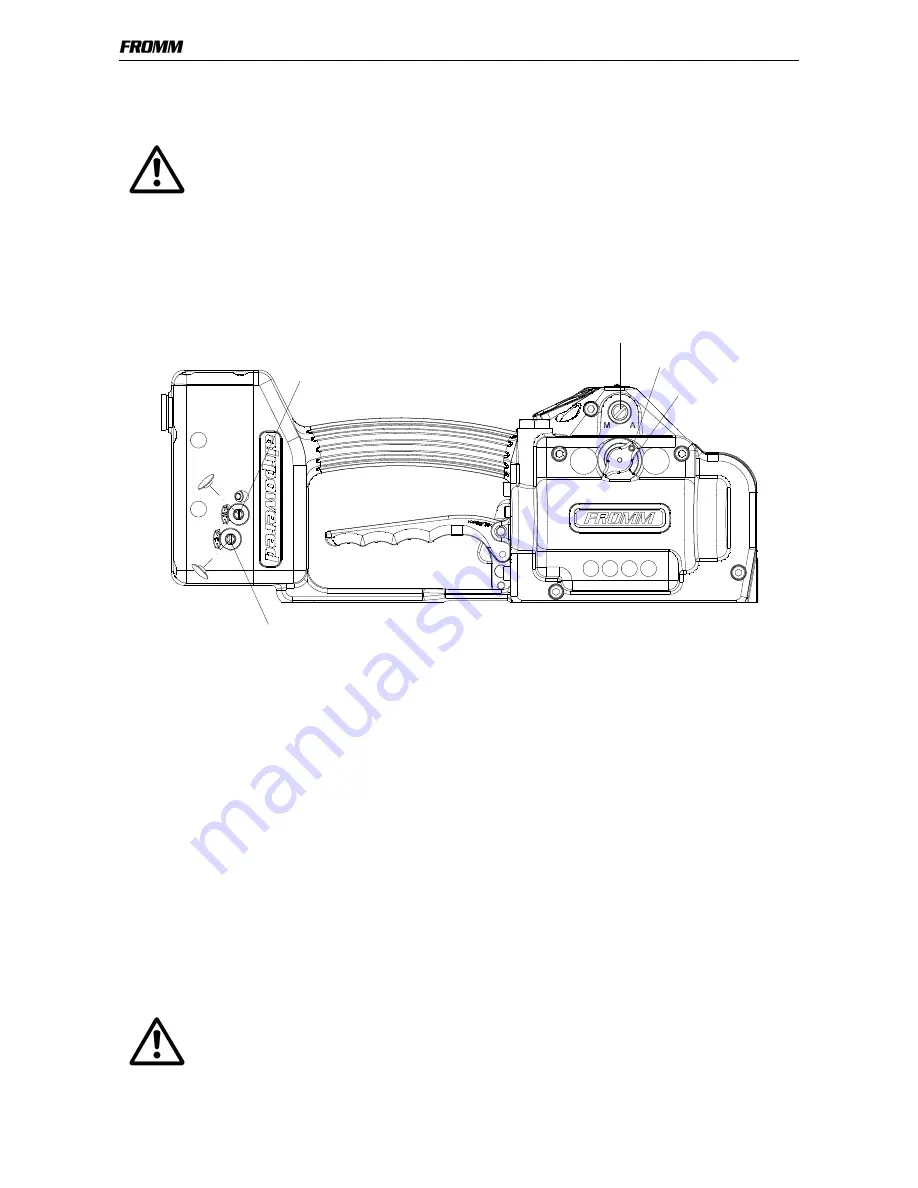

5.4.1 Preselecting of strap tension and tensioning speed

Do not adjust the tensioning force too high.

If the tensioning force is higher than the tensioning strength of the strap,

the strap will tear while the tensioning.

Tensioning force and tensioning speed can be preselected at the control head.

• Loose lock screw;

• press the control head against the tool and turn it.

Turning clockwise increases;

turning counterclockwise decreases the tensioning force and the tensioning speed resp..

• Tight lock screw.

5.4.2 Adjustment of the welding time

Depending on the size and quality of the strap, different welding times are required.

The welding time can be set at the throttle screw using a screw-driver 4.5 x 0.8 mm .

• Remove the cap cover.

• Turning the screw-driver clockwise increases the welding time.

• Turning the screw-driver counter-clockwise decreases the welding time.

Adjustment in small steps is recommended!

5.4.3 Adjustment of the cool down time

In order to obtain a high seal strength, the welded straps must cool down under pressure of the sealing jaws.

The required cool down time between 1 to 5 seconds depends on the strap dimension, the strap quality and

the strap tension.

The time can be adjusted at the throttle screw for cool down time using a screw-driver of 4.5 x 0.8 mm.

• Remove the cap cover.

• Turning the screw-driver clockwise increases the cool down time.

• Turning the screw-driver counter-clockwise decreases the cool down time.

Adjustment in small steps is recommended!

Do not adjust the cool down time too short.

If the cooling time is too short, the not yet solidified strap is pulled apart or

the strapping breaks.

Lock screw

Adjustment screw

Throttle screw for welding time

Throttle screw for cooling down time

Control head

for operation mode