135

EN

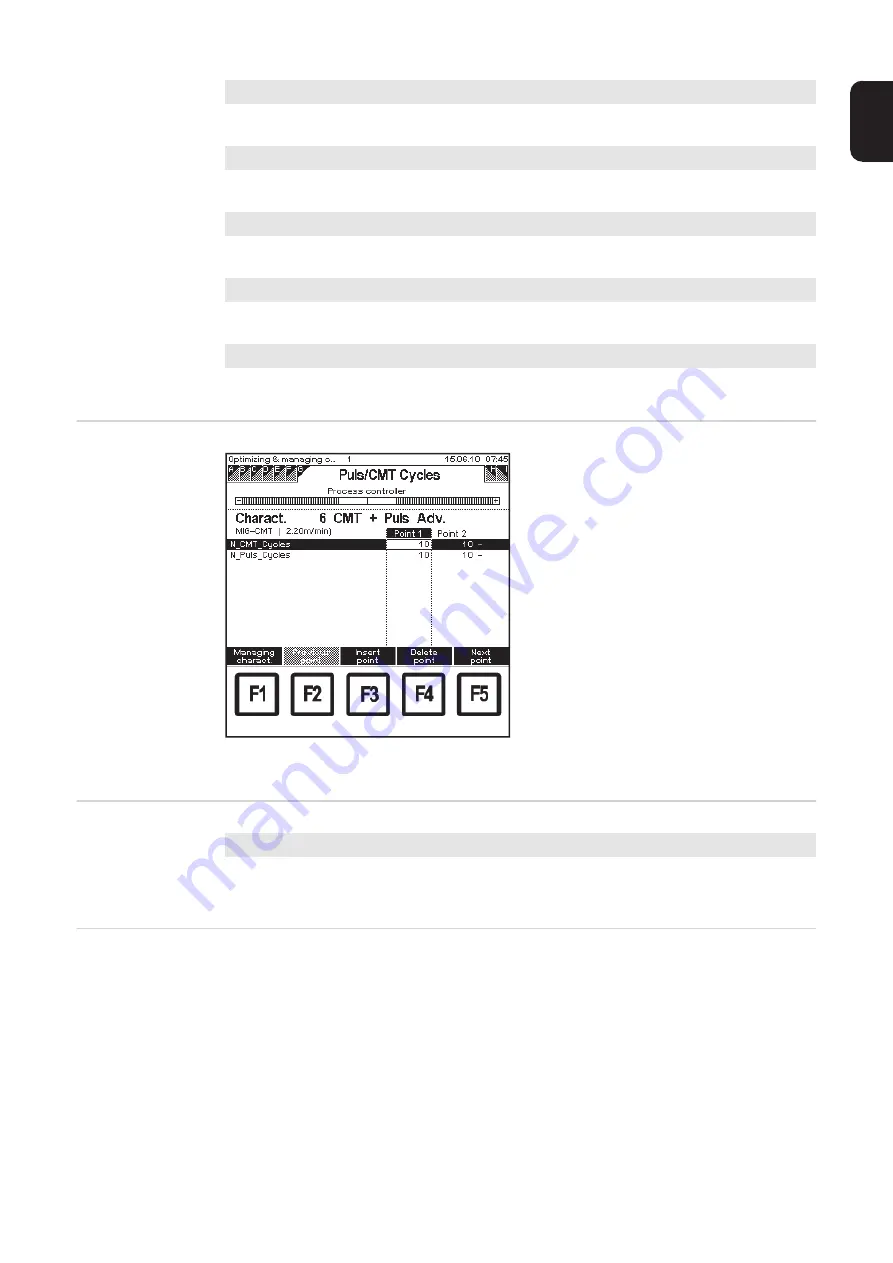

Pulsed/CMT cy-

cles

"Pulsed/CMT cycles" screen for CMT + P ADV charac-

teristics

N_CMT_Cycles

Number of CMT cycles

N_Puls_Cycles

Number of pulse cycles

End of welding

Guideline values

Current guideline value

The current guideline value [A] is normally determined by trial and error or by performing

a test weld.

Guideline value for material

The guideline value for the material strength [mm] is normally determined by trial and error

or by performing a test weld

Voltage guideline value

The voltage guideline value [V] is normally determined by trial and error or by performing

a test weld. On the TS 4000/5000 and TPS 2700/4000/5000 power sources, the voltage

guideline value corresponds to the voltage on the contact tube.

k_I_p1_reg_gain

Effect of deviations [%] on the pulsing current

k_Vd_reg_gain

Effect of deviations [%] on the wirefeed speed

k_I_b_reg_gain

Effect of arc length correction [%] on the base current

I_p1_reg_delta_min

Lower control limit for the pulsing current Ip1 [A]

I_p1_reg_delta_max

Upper control limit for the pulsing current Ip1 [A]

t_burnback

Duration of the currentless wire withdraw [ms] after the welding current has been

switched off (v

D

= -6 m/min)

Summary of Contents for RCU 5000i

Page 2: ...2 ...

Page 4: ...4 ...

Page 200: ...200 Backup screen All data from the remote control unit are sa ved onto the memory card ...

Page 202: ...202 Restore screen The last Data screen called up appears ...

Page 207: ...207 EN Machine pre sets MIG MAG screen MIG MAG screen appears ...

Page 210: ...210 Machine pre sets e g MIG MAG screen The last Data screen called up appears ...

Page 242: ...242 ...

Page 243: ...Appendix ...

Page 244: ...244 Spare parts list RCU 5000i ...

Page 245: ...245 ...

Page 246: ...246 ...

Page 247: ...247 ...