I 35

Reserved

36

Reserved

37

NC

TC

= Robacta TC 2000

WC

= wire cutter

RR

= Robacta Reamer

Optional Connec-

tions Robot Con-

trol Unit (Field-

bus)

If the welding torch service station is equipped with an optional fieldbus as a robot con-

trol unit connection, then the connection is described in the separate Operating Instruc-

tions for the fieldbus:

42,0410,2245 ... ProfiNet Robacta TSS /i

42,0410,2434 … DeviceNet Robacta TSS /i

42,0410,2435 … ProfiBus Robacta TSS /i

42,0410,2436 … EtherCAT Robacta TSS /i

42,0410,2550 ... Ethernet IP Robacta TSS/i

Assignment of

external optional

equipment con-

nection

CAUTION!

Danger from overcurrent.

Damage to the bearings may result.

▶

Provide the power supply with 1.5 A fuse protection against overcurrent.

NOTE!

To avoid interference, keep the line length between the welding torch service sta-

tion and the robot control unit as short as possible.

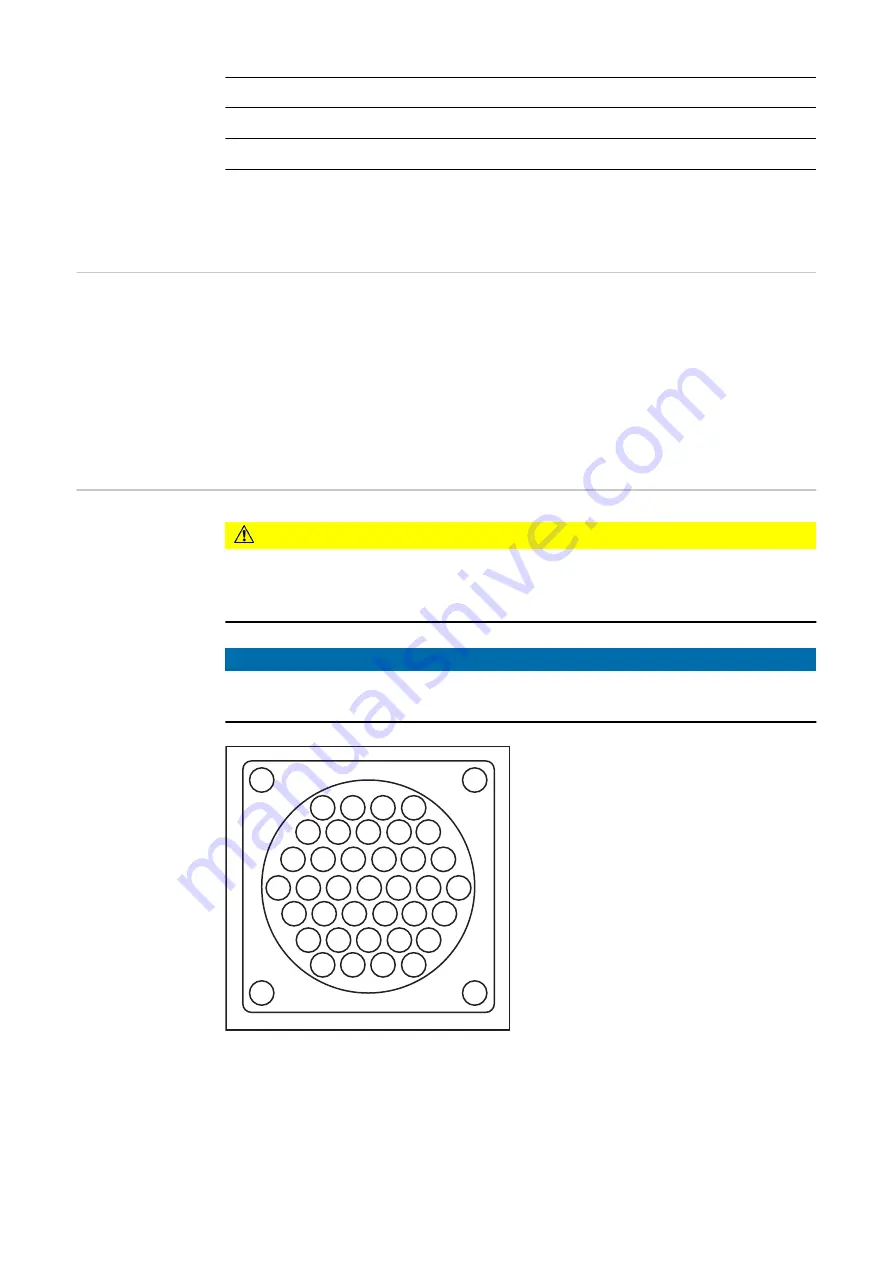

1

2

3

4

9

8

7

6

5

10

11

12

13

14

15

22 21 20 19 18 17 16

28 27 26 25 24 23

33 32 31 30 29

37 36 35 34

I = Input:

from the optional equipment to the welding

torch service station

O = Output:

from the welding torch service station to

the optional equipment

26

Summary of Contents for Robacta TSS /i

Page 2: ......

Page 11: ...General 11 ...

Page 12: ...12 ...

Page 18: ...18 ...

Page 19: ...Operating controls connections and mechanical components 19 ...

Page 20: ...20 ...

Page 32: ...32 ...

Page 33: ...Installation and Startup 33 ...

Page 34: ...34 ...

Page 61: ...12 12 12 Connect the compressed air supply 61 EN US ...

Page 64: ...64 ...

Page 65: ...Cleaning Program Sequence 65 ...

Page 66: ...66 ...

Page 68: ...A B C D E F G 68 ...

Page 79: ...Reset external signal Internal valve brush cleaning 79 EN US ...

Page 84: ...Reset external signal Cut wire electrode End of the cleaning process Welding 84 ...

Page 85: ...Troubleshooting Maintenance and Disposal 85 ...

Page 86: ...86 ...

Page 97: ...Appendix 97 ...

Page 98: ...98 ...