12

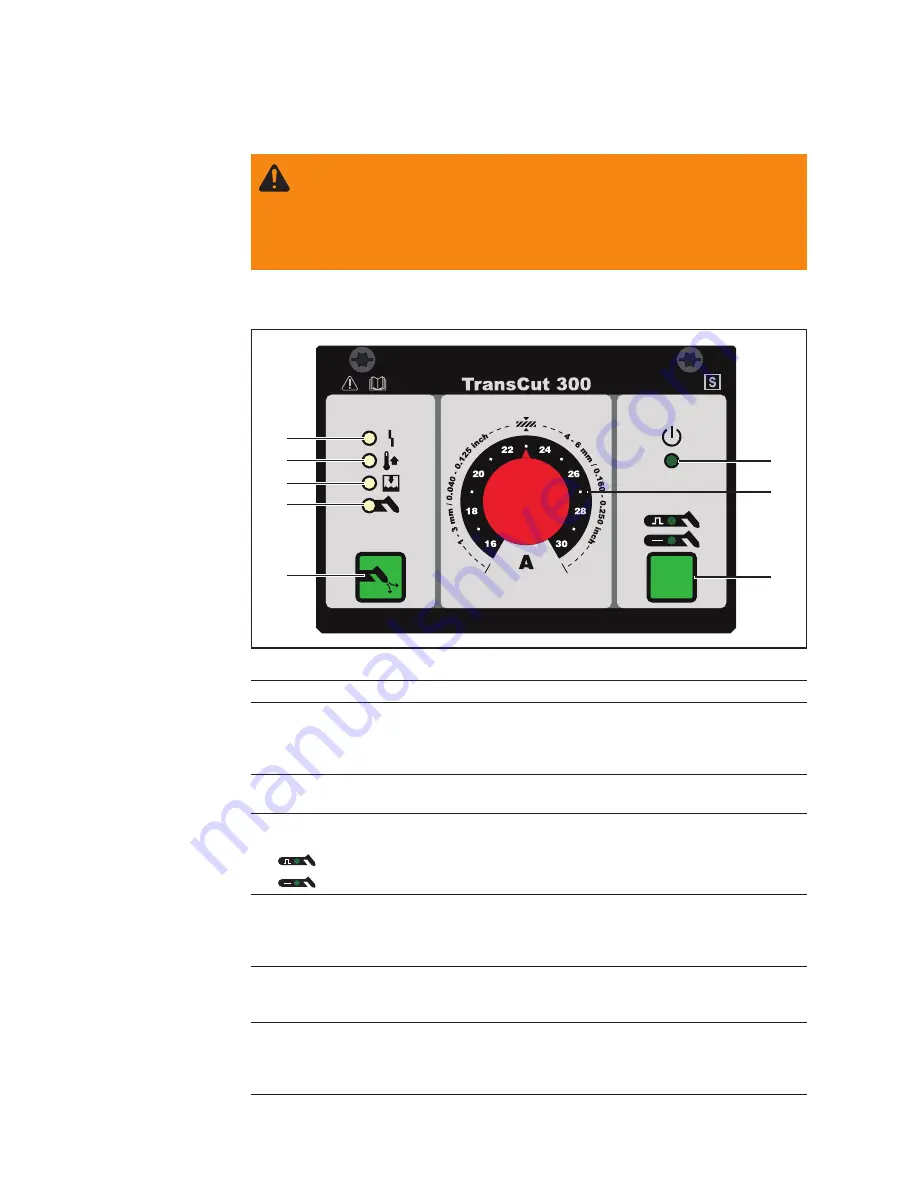

Controls and connections

WARNING!

Operating the equipment incorrectly can cause serious injury and

damage. You should not use the functions described until you have thoroughly

read and understood the following documents:

-

These operating instructions

-

all operating instructions for the system components, especially the

“Safety rules”

n° Function

(1) ‘Standby’ indicator

-

flashes on and off whilst the device is in its warm-up and reheating phase

-

flashes on and off whilst the cutting torch is in its cool-down phase

-

lights steady when the device is ready for use

(2) Cutting current parameter

for selecting the cutting current

(3) Mode button

for selecting the operating mode for different materials

Pulse mode. Recommended for cutting ferrometallic materials

Standard mode. Recommended for cutting aluminium

(4) Fill button

For filling the hosepack and cutting torch with the cutting medium. Must be perfor-

med every time the tank is filled and when the device has not been used for a period

of time.

(5) Torch indicator

-

comes on when wear parts of the cutting torch are fitted incorrectly or worn

-

comes on when the cutting torch’s protective cap is fitted incorrectly

(6) Fill level indicator

-

comes on when most of the cutting medium has been used up. Keep a new

cartridge of cutting medium at the ready, or fill up the tank.

-

flashes on and off if the tank is empty

General remarks

Controls

(8)

(7)

(6)

(4)

(1)

(3)

(2)

Fig. 2 Controls

(5)

Summary of Contents for TransCut 300

Page 2: ......

Page 4: ......

Page 14: ...10 ...

Page 28: ...24 ...

Page 31: ...TransCut 300 plasma cutting device ...

Page 32: ...TransCut 300 cutting torch ...