20

Troubleshooting

WARNING!

An electric shock can be fatal. Before opening up the machine

-

Move the mains switch to the “O” position

-

Unplug machine from the mains

-

Put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

-

Using a suitable measuring instrument, check to make sure that electri-

cally charged components (e.g. capacitors) have been discharged

CAUTION!

Inadequate PE conductor connections can cause serious injury

and damage. The housing screws provide a suitable PE conductor connection

for earthing (grounding) the housing and must NOT be replaced by any other

screws that do not provide a reliable PE conductor connection.

General remarks

At some points the arc does not penetrate the workpiece completely

The cutting current is set to its maximum value

Cause:

Cutting speed too fast or distance from workpiece too great

Remedy:

Reduce cutting speed or distance from workpiece

Cause:

Wearing parts are worn excessively

Remedy:

Replace wearing parts

Cause:

Poor earth connection

Remedy:

Check contact between earth terminal and workpiece

Poor cutting performance

Cause:

Cutting current too low or distance from workpiece too great

Remedy:

Increase cutting current or reduce distance from workpiece

Cause:

Poor earth connection

Remedy:

Check contact between earth terminal and workpiece

Cause:

Very long mains lead extension

Remedy:

Use shorter mains lead extension

Arc breaks during cutting

Cause:

Poor earth connection

Remedy:

Check contact between earth terminal and workpiece

Cause:

Wearing parts are worn excessively

Remedy:

Replace wearing parts

Cause:

Very long mains lead extension

Remedy:

Use shorter mains lead extension

Cause:

Insufficient generator output

Remedy:

Use more powerful generator

Fault diagnosis

Summary of Contents for TransCut 300

Page 2: ......

Page 4: ......

Page 14: ...10 ...

Page 28: ...24 ...

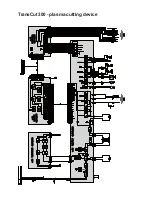

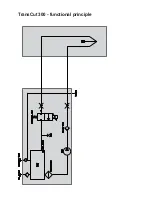

Page 31: ...TransCut 300 plasma cutting device ...

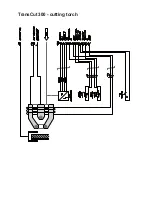

Page 32: ...TransCut 300 cutting torch ...