21

EN

Excessive formation of „dross“ during the cutting operation

Cause:

Cutting speed too fast

Remedy:

Reduce cutting speed

Cause:

Cutting speed too slow

Remedy:

Increase cutting speed

Cause:

Cutting current too low

Remedy:

Increase cutting current

Cause:

Wrong operating mode selected

Remedy:

Select a different mode

Cause:

Cutting torch applied incorrectly

Remedy:

Apply cutting torch with a slight forward inclination

Steam escaping between body of torch and protective cap

Cause:

Protective cap fitted to cutting torch incorrectly

Remedy:

Tighten protective cap on cutting torch

Cause:

Cutting nozzle cone dirty or damaged

Remedy:

Clean cutting nozzle or install new cutting nozzle

Service codes

displayed

Fault diagnosis

(continued)

Excess temperature indicator lit

Cause:

Device overheating

Remedy:

Leave device switched on and wait until it has cooled down.

The indicator is turned off automatically as soon as the device is

ready for operation again.

Fill level indicator lit

Cutting can nevertheless continue.

Cause:

Most of the cutting medium in the tank has been used up

Remedy:

Keep a cartridge of cutting medium at the ready or refill tank

Fill level indicator flashing

Cutting can no longer be continued

Cause:

No cutting medium in tank

Remedy:

Fill tank with cutting medium

Torch indicator lit

Cause:

Protective cap fitted to cutting torch incorrectly

Remedy:

Fit protective cap correctly

Cause:

Wearing parts on cutting torch fitted incorrectly

Remedy:

Fit wearing parts correctly

Cause:

Wearing parts faulty or worn

Remedy:

Replace wearing parts

Error indicator lights up

Cause:

Internal machine fault

Remedy:

Switch device off and on again If the error recurs after the device is

switched on again you should notify After-Sales Service immediately.

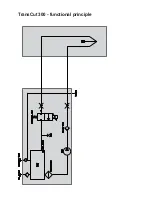

Summary of Contents for TransCut 300

Page 2: ......

Page 4: ......

Page 14: ...10 ...

Page 28: ...24 ...

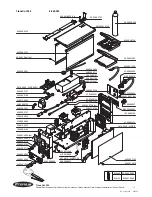

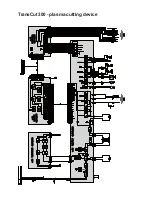

Page 31: ...TransCut 300 plasma cutting device ...

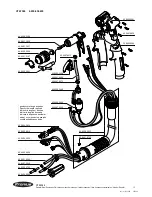

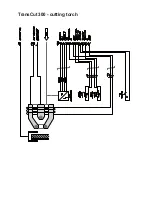

Page 32: ...TransCut 300 cutting torch ...