22

Care, maintenance and disposal

General remarks

Under normal operating conditions the charger requires only a minimum of care and

maintenance. However, it is vital to observe some important points to ensure the plasma

cutting system remains in a usable condition for many years.

Every start-up

-

Check wearing parts of torch and replace them as necessary

-

Check fill level of cutting medium and top up as necessary

NOTE!

Use only original cutting medium from the manufacturer for filling the

device. Other cutting media will be unsuitable.

-

Check mains plug and mains cable, as well as cutting torch and earth connection

for damage

-

Check whether the allround distance of 0.5 m (1ft 8in.) is kept to ensure that the

cooling air can easily flow and escape.

NOTE!

Air inlets and outlets must never be covered, not even partially.

-

Dismantle machine side panels and clean inside of machine with dry reduced

compressed air

NOTE!

Risk of damage to electronic components. Do not bring the air nozzle

too close to the electronic components.

Every 6 months

Disposal

Dispose of in accordance with the applicable national and local regulations.

WARNING!

An electric shock can be fatal. Before opening up the machine

-

Move the mains switch to the “O” position

-

Unplug machine from the mains

-

Put up an easy-to-understand warning sign to stop anybody inadvertently

switching it back on again

-

Using a suitable measuring instrument, check to make sure that electri-

cally charged components (e.g. capacitors) have been discharged

CAUTION!

Danger of burns from hot cutting torch. The cutting torch must be

cleaned and wearing parts replaced only after the cutting torch has cooled

down.

Summary of Contents for TransCut 300

Page 2: ......

Page 4: ......

Page 14: ...10 ...

Page 28: ...24 ...

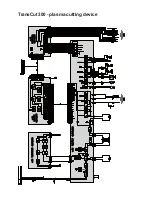

Page 31: ...TransCut 300 plasma cutting device ...

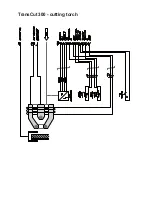

Page 32: ...TransCut 300 cutting torch ...