*NOTE- When attaching heavy scraper kit, do

NOT tighten any hardware until stated in direc-

tions. Adjustments may need to be made.

Reference Figure 2

To attach heavy scraper kit to disc, place scraper

bar top plate (ref. #2) on top of gang beam and

scraper mount bracket (ref. #1) on bottom of

gang beam. Using 5/8" x 5" Gr. 2 bolts (ref. #3),

fasten both pieces together around gang beam

with 5/8" lock washer and hex nut (ref. #4 & #5).

There should be two scraper mount bracket

assemblies for each gang beam with the place-

ment being close to each gang hanger. Some

adjustment may need to be made when mount-

ing scraper arm & blade assemblies (ref. #16).

Take heavy scraper bar (ref. #13) and mount on

top of scraper mount bracket assembly with

1-hole scraper bar clamp (ref. #11). Use a 1/2" x

2 1/2" Gr. 2 bolt (ref. #6) and a 1/2" flange locknut

(ref. #7) to fasten. Scraper arm & blade assem-

blies (ref. #16) are now mounted on bottom of

scraper bar (ref. #13). There are two different

sides of scraper arm & blade assemblies (ref.

#16). One side fits the right front and left rear, the

other side fits the left front and right rear. When

mounting scraper arm & blade assemblies (ref.

#16) to bottom of scraper bar (ref. #13), use

2-hole clamp (ref. #12) on top of scraper bar (ref.

#13) and fasten together with 1/2" x2 1/2 GR 2

bolt(ref. 6) and 1/2” flange locknut (ref. #7).

Scraper arm & blade assemblies are not provided

for outside front and inside rear blades! Once all

scraper arm & blade assemblies (ref. #16) have

been mounted, now is the time to make adjust-

ments to scraper mount bracket assemblies, if

needed. When adjustments are made, tighten

scraper mount bracket assemblies to gang beam

and tighten scraper bar (ref. #13) to scraper

mount bracket assembly using 1-hole scraper

bar clamp (ref. #11) and hardware (ref. #6 & #7).

Scraper arm & blade assemblies (ref. #16) should

then be positioned as close to the disc blade as

possible without touching it. Turning the gang

after mounting each scraper arm & blade assem-

bly (ref. #16) will help determine the correct

mounting position of each one. This is recom-

mended to prevent dragging or binding of the

gang.

*NOTE- Tighten all fasteners after setting and

adjustments are made.

*NOTE- Re-tighten all fasteners after first opera-

tional use.

Heavy Scraper Kit Mounting Instructions

Optional Equipment 16

Summary of Contents for DH1376

Page 1: ...DH13_5TL15193_7 10 2014 DH1376 DH1380 DH1396 DISK HARROWS O P E R A T O R S M A N U A L...

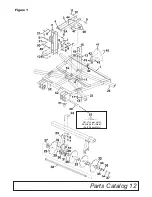

Page 15: ...Parts Catalog 12 Figure 1 Set of Lower Hitch Bushings for iMatch Sold Separately...

Page 23: ...Notes 20 Notes...

Page 24: ...2014 Monroe Tufline Manufacturing Inc All Rights Reserved PART NO 5TL15193...