INSTALLATION AND MAINTENANCE MANUAL

TRANSLATION OF THE

ORIGINAL DOCUMENT

For additional copies visit:

www.frost‐trol.com

WALEN SOLID

LINES

D008586

Versión:

1

-20-

4.

MAINTENANCE AND CLEANING

Unplug the cabinet before performing any form on internal servicing of

the unit.

Any maintenance operation not described in these instructions must be

done by authorized personnel.

Perishable products are sensitive to the bacteria proliferation. Therefore, cabinet

cleaning has to be made following next generic rules.

Establish a routine cleaning schedule to ensure an adequate level of hygiene of

your cabinet. In this way you will ensure an optimal performance of the cabinet

and a longer service life.

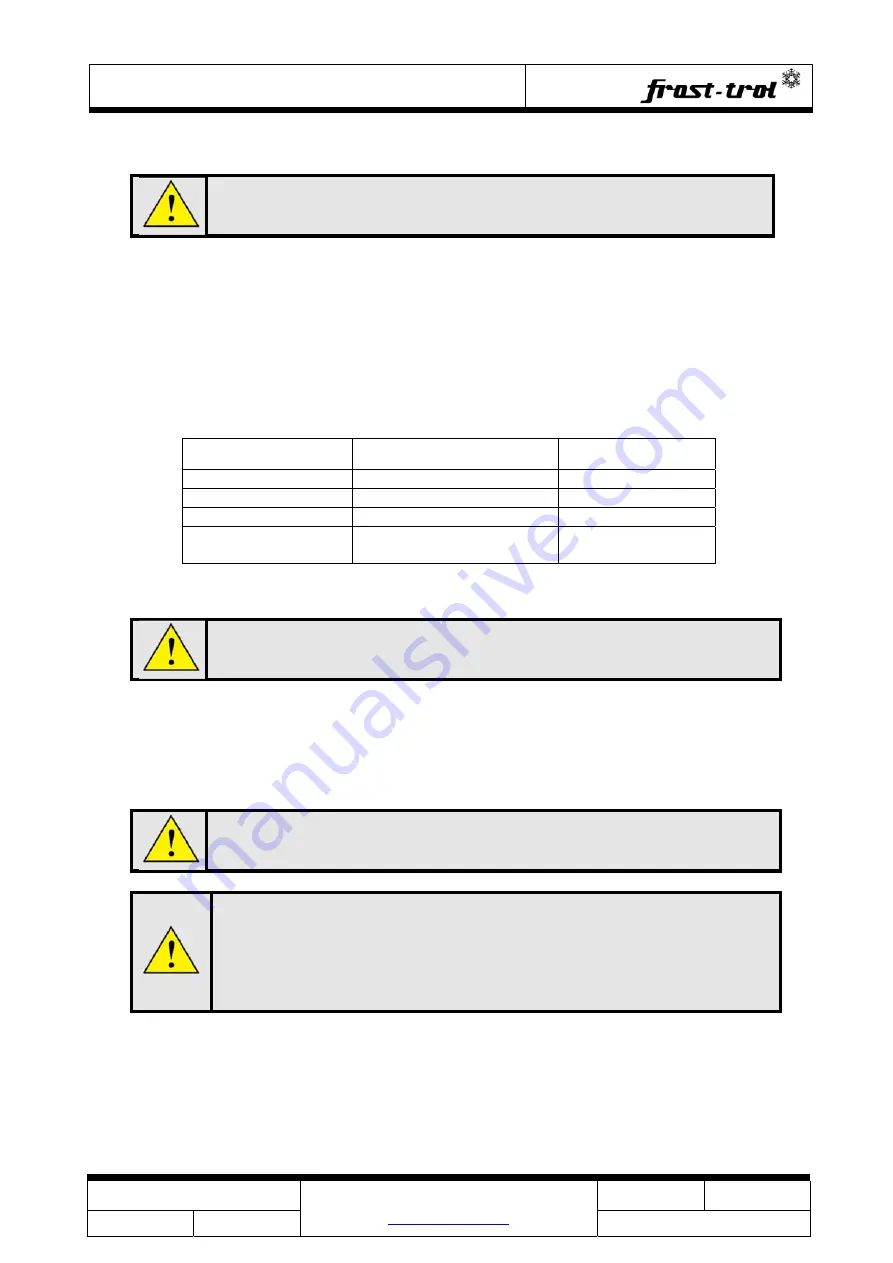

TYPE ZONE

PÉRIODICITÉ

CLEANING EXTERNAL

PARTS WEEKLY

CLEANING INNER

PARTS MONTHLY

MAINTENANCE DOORS MONTHLY

CLEANING GENERAL

EVERY 2 OR 3

MONTHS

Tabla 4. Cleaning routine

Do not allow any water to spatter or be sprayed over the unit’s electrical

elements. Should this happen, make sure that they are dry before the

unit is started up again.

If cabinet has to be shutoff for a long time, take out perishable products located

inside, switch-off the unit and then, clean the cabinet following the procedure

described before. Finally, leave the doors half-open to avoid unpleasant smells.

IMPORTANT!

The components of the refrigerating circuit must not be cut or separated.

WARNING: In appliances employing transcritical R744

refrigeration system is under high pressure. Do not tamper with the

system. It must be serviced by qualified persons only. Contact qualified

service personal before disposal.

4.1.

GENERIC CLEANING ROUTINE

Clean the cabinet with non-abrasive detergents. Cleaning products have to be

suitable for use with foodstuffs. Ensure a good rinse to remove all detergent

Summary of Contents for WALEN

Page 4: ......