3

2.2 Equipment

Assembly

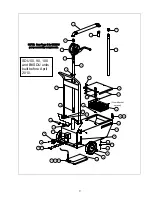

Assembly of the unit is a four-step process:

1.

Remove the two bolts from the handle-mounting bracket and raise the handle to the upright

position. Reinstall the bolts in the bracket and tighten to 8 ft/lbs.

2.

Ensure the O-rings and the bottom 2 inches of the suction tube are lubricated with

Accrolube

with Teflon

or an equivalent light oil or grease.

3.

Turn the pump and suction tube upside down and carefully pour no more than one cup of

cooking oil down the tube. Rotate the pump handle slowly three or four times to prime the

pump.

4.

Insert the suction tube through the pipe bracket on the handle and into the pickup tube on top of

the reservoir. Push down on the pump assembly and ensure the suction tube is fully seated.

2.3 Equipment

Operation

WARNING

DO NOT use this unit to dispose of water or Boil-out solution. Introduction of water

or solvents into the unit will permanently damage the pump.

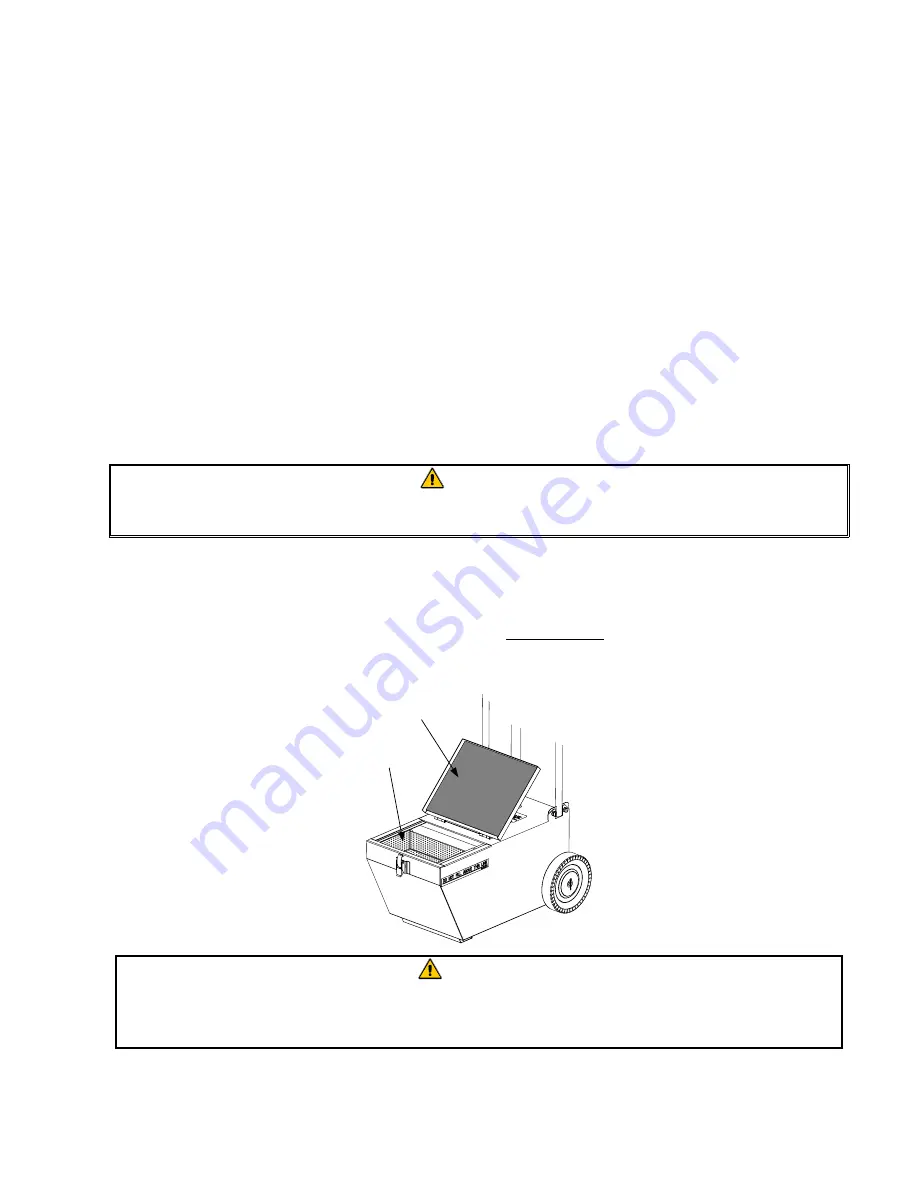

1.

Turn the fryer off prior to draining into SDU. If so equipped, ensure the fryer drainpipe is firmly

threaded into the frypot drain valve.

2.

Open the cover, verify that the crumb screen and rubber gasket on the inside cover are in place,

and position the unit so that the opening is directly under the frypot drainpipe.

Cover Gasket

Crumb Tray

DANGER

Before each use inspect the cover to ensure the cover gasket is present and

properly placed. DO NOT use the disposal unit if this gasket is damaged or

missing.

3.

Slowly

open the drain valve. Regulate flow with the drain valve to prevent splashing.

Summary of Contents for BKSDU

Page 15: ......