WARNING:

For correct operation of this appliance, it is essential to observe the manufacturer’s instructions.

I. Before You Begin

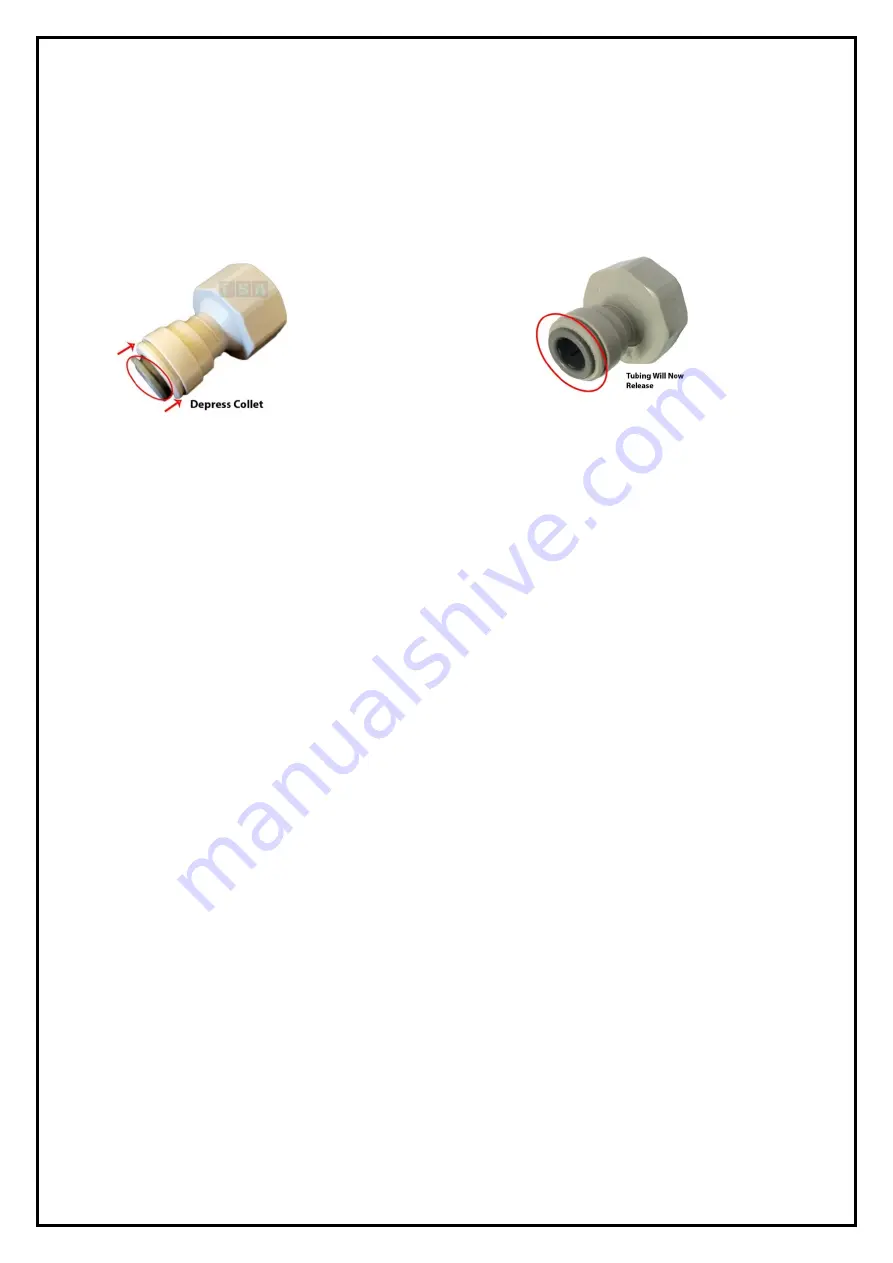

Quick Connect Fittings: If you come across a push-fit fitting, you need to firmly push the tubing into the

opening until you feel a “click” which signifies that the tubing has pushed through the internal O-ring and is

seated correctly. If leaking occurs, it may be due to roughly cut tubing OR the tubing is not pushed in far

enough. To remove tubing from push-fit fittings, depress the floating collet (shown in below photo), then pull

the tubing out.

NOTE: You will need to remove the Blue/White plug from the end of the outlet line marked

“Drinking Water”. Use the above steps to remove this plug. Do not discard the plug as it is used to

seal the drinking water line between use to prevent bacterial contamination.

II. Important Note:

Laws and regulations prevent us from wet-testing these filtration systems prior to sending them out.

Therefore, during assembly of these systems they are not pressure tested so it is possible to have a small

leak in a connection (which is simply fixed by re-seating the tubing or tightening a fitting). As the filters are

dry packed, the systems will require flushing before first use – Our systems purposely have the inlet filter

disconnected from the membrane so that you can do an initial flush of the pre filters to prevent fouling the

membrane with carbon fines. When first flushing the unit – remember that this tubing is disconnected and

should be aimed into a sink/bucket during the flushing process. When flushing is finished – re-connect the

tubing to the inlet of the membrane housing (Screw Cap End).

Reverse Osmosis Filtration

I. Overview

The Reverse Osmosis Membrane is the workhorse of any RO system. It is constructed from a wrapped

semi-permeable membrane material that uses pressure to separate impurities such as ions, minerals and

other larger molecules from the water, carrying them to waste.

*Reverse Osmosis membranes do not have a litre Capacity for filter replacements due to the variables that

can make the filter life vary significantly. This is mostly due to the water quality. The most accurate way to

test a RO membrane for effectiveness is to use a TDS Meter. TDS meters measure the total dissolved

solids in ppm in the water. To test your membrane, get a baseline reading out of your tap (unfiltered water)

and then compare that to a reading directly off the membrane (disconnect the tube before it goes into the

post filter cartridge). You can expect to get a difference of approx. 90-98% between the readings which

indicate that the membrane is functioning correctly. If this % is beginning to drop below 90% it suggests

that the RO membrane requires replacement

II. Feed Water Conditions

•

Pressure: 50 - 100 psi

•

TDS: <1,000 mg/L

•

Hardness: <250mg/L

•

Iron: <0.02

•

Manganese: <0.01

•

Temperature: 1°C - 26°C