CA / CT SERIES

CAP600

Page

9 of 30

REV D July 2013

Installation Procedure

Step 1 – Select a proper location for installation

Select a clean, dry, well lit area with a rigid floor strong enough to support the compressor and

with adequate ventilation. Avoid placement of the compressor in an area that is excessively

hot, dusty, humid or contaminated with foreign gases such as ammonia or acid fumes.

The unit should never be operated at ambient temperatures above 104°F or below 32°F. If the

ambient temperature is below 40°F, FS Curtis recomm ends using Arctic oil. Maintenance

checks are required daily, thus three (3) feet of space needs to be provided around the

compressor for proper inspection.

Note – If the unit or air intake is to be located outdoors, please contact your local

distributor for additional instructions.

Step 2 – Remove the skid

Remove and discard the shipping skid. The compressor should NEVER be operated on a

skid.

Step 3 – Prepare the mounting surface

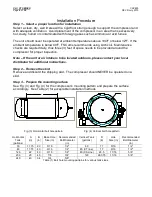

See Fig. (3) and Fig. (4) for the compressor’s mounting pattern and prepare the surface

accordingly. See Table (2) for acceptable installation methods

B

A

D

Fig. (3) Horizontal bolt hole pattern

Fig. (4) Vertical bolt hole pattern

Horizontal

Tank

(gallons)

A

(in)

B

(in)

Base Hole

Size (in)

Recommended

Bolt Diameter

(in)

Vertical Tank

(gallons)

D

(in)

Hole

Size (in)

Recommended

Bolt Diameter

(in)

30

17.75

23

9/16

1/2"

60

17

9/16

1/2”

80

17.75

40

9/16

1/2”

80 (CT line)

17

9/16

1/2"

120

22

40

9/16

1/2”

80 (CA Line)

22.5

11/16

5/8”

200

28

40

7/8

3/4”

120

26.375

11/16

5/8”

240

40

54

3/4

5/8”

Table (1) Bolt hole mounting patterns for various tank sizes.