CA / CT SERIES

CAP600

Page

21 of 30

REV D July 2013

Oil

OIL RECOMMENDATION

Use Genuine CURTIS-LUBEPLUS Lubricants. Specially formulated for Curtis Reciprocating

Air Compressors. Non-Detergent type with anti-foam, anti-rust and oxidation inhibitors.

Under normal operating temperatures, use FSC-1000 ISO68 CURTIS-LUBEPLUS.

In areas with very hot ambient air temperatures, FS Curtis recommends using ISO100 FSC-

1000A CURTIS-LUBEPLUS.

1. For proper lubrication the compressor shall not be operated below the minimum or above

the maximum R.P.M. recommended for the various models.

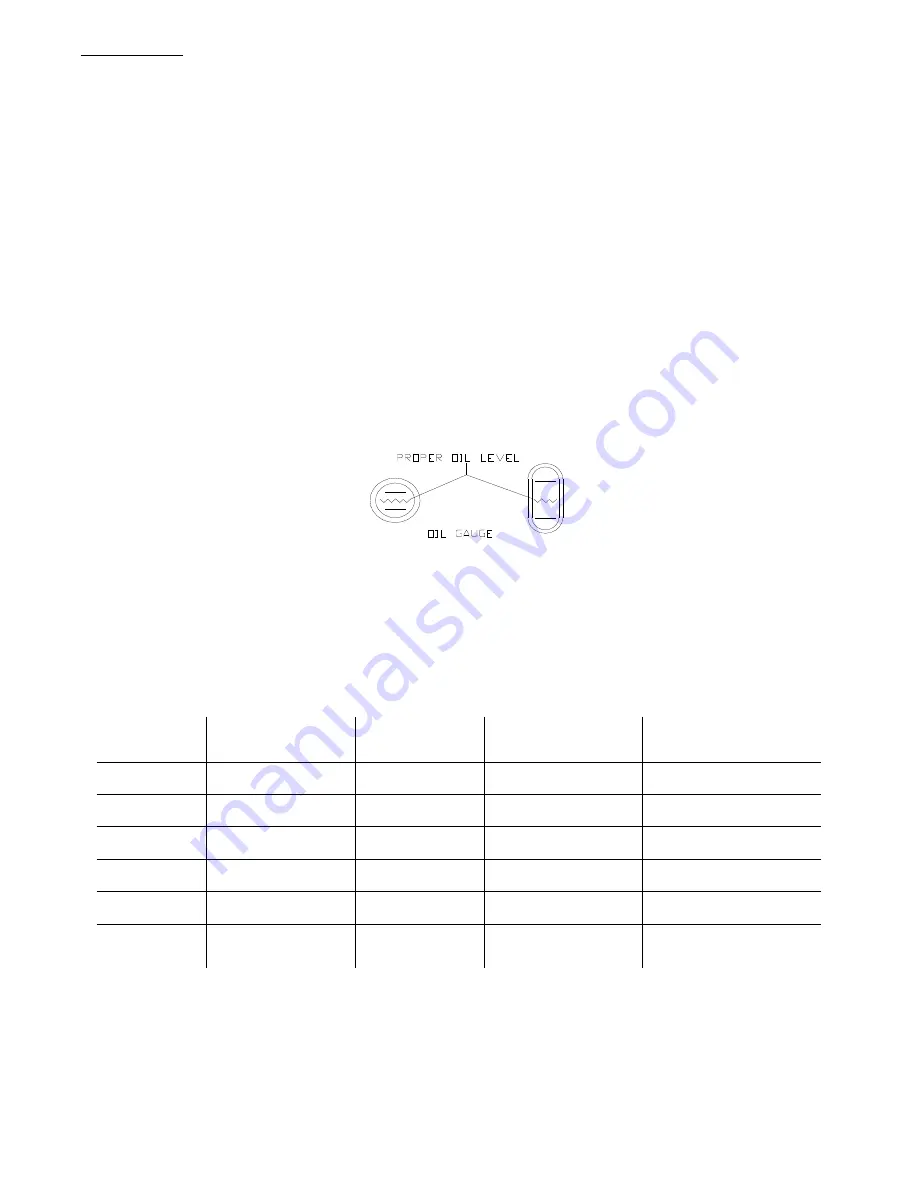

2. Maintain oil level mid-way between the upper and lower lines of the crankcase sight gage.

Fig (12) Oil sight glass reading

3. Stop compressor to add and gauge oil.

4. Do not fill above the upper line and do not operate compressor with oil level below the lower

line.

OIL CAPACITIES

MODEL

NUMBER

HORSEPOWER

(hp)

MIN

RPM

MAXIMUM

RPM

OIL CAPACITY

E50

5

500

1050

1½ QUARTS

E57

5 – 7½

800

1250

2 QUARTS

E71

10

500

1050

2½ QUARTS

E15

15

500

1050

5 QUARTS

CT55

5

650

1050

1 ½ QUARTS

CT75

7.5-10 electric

13-14 gas

650

1000

3 QUARTS

Table (4)