CAP-600

4

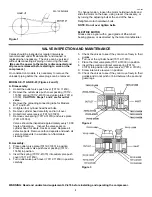

Figure 1

To change tension, loosen the motor hold-down bolts and

slide the motor on the base, using a lever if necessary, or

by turning the adjusting bolt at the end of the base.

Retighten motor hold-down bolts.

NOTE: Do not over tighten belts.

ELECTRIC MOTOR

Grease once a year with a good grade of lithium ball

bearing grease, or as directed by the motor manufacturer.

VALVE INSPECTION AND MAINTENANCE

Valves should be inspected at regular intervals as

recommended under "Maintenance" and cleaned or

replaced when necessary. The valve can be serviced

without disconnecting air piping or removing the head.

(Be sure the power to the motor is disconnected and

all pressure released before starting to work on the

compressor.)

On constant run models, it is necessary to remove the

unloader piping before the valve plugs can be removed.

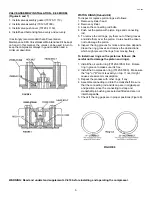

MODELS E-11 AND E-23 (Figures 2 and 3)

A. Disassembly:

1. Unbolt the outlet valve push cover (70112- 11450).

2. Remove the outlet valve push cover packing (70112-

11650), spring (70112-41070) and valve plate (70112-

31030).

CAUTION: Steps 1 and 2 are for outlet

valve.

3. Remove the unloading connecting tube for Models

E-11 and E-23.

4. Untighten four cylinder head fixed bolts.

5. Remove cylinder head carefully and turn it over.

6. Unbolt inlet valve receiver (70112-31020).

7. Remove valve spring (70112-31070) and valve plate

(70112-31030).

Valves should be inspected approximately every 1,000

hours of operation. Inspect the valve seats on

cylinder head for dents, cracks or wear. Replace all

defective parts. Remove carbon deposits and wash all

valve components in a suitable non-flammable

cleaning fluid.

B. Assembly:

1. Place outlet valve plate (70112-31030) in position.

2. Place the outlet valve push cover packing (70112-

11650) in position.

3. Insert the spring (70112-41070) into outlet valve push

cover (70112-11450).

4. Turn outlet valve push cover (70112-11450) in position

carefully.

5. Check the valves to see if they can move freely in their

guides.

6. Turn over the cylinder head (70112-11010).

7. Place the inlet valve plate (70112-31030) in position.

8. Insert the small end of inlet valve spring (70112-

31070) into position of valve receiver (70112- 31020).

9. Screw inlet valve receiver in position.

10. Check the valves to see if they can move freely in their

guides and do not pinch or bind between the seat and

guard legs.

Figure 2

Figure 3

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

Summary of Contents for CA series

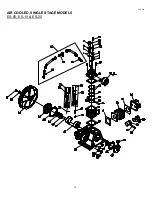

Page 12: ...CAP 600 12 AIR COOLED SINGLE STAGE MODELS ES 05 ES 10 ES 20 ...

Page 20: ...CAP 600 AIR COOLED SINGLE STAGE MODEL ES 150A 18 ...

Page 22: ...CAP 600 AIR COOLED SINGLE STAGE MODEL ES 150B 18A ...

Page 24: ...CAP 600 20 AIR COOLED TWO STAGE MODELS E 11 E 23 ...

Page 30: ...CAP 600 AIR COOLED TWO STAGE MODEL E 25 25A ...

Page 34: ...CAP 600 26 AIR COOLED TWO STAGE MODEL E 35 ...

Page 36: ...AIR COOLED TWO STAGE MODEL E 57 E57A CAP600 28 ...

Page 39: ...CAP 600 31 VALVE PLATES DESIGNS FOR E 57 COMPRESSOR ...

Page 47: ...CAP 600 NOTES 39 ...