MAINTENANCE /

REP

AIR

TROUBLESHOOTING

OPERA

TION

SAFETY

/

SPECIFICA

TIONS

GETTING

ST

ARTED

10

ASSEMBL

Y

/

INST

ALLA

TION

OPERATING INSTRUCTIONS

All lubricated compressor pumps discharge some condensed water and oil with the compressed air. Install

appropriate water/oil removal equipment and controls as necessary for the intended application.

Failure to install appropriate water/oil removal equipment may result in damage to

machinery or workpiece.

Start-up / Break-in Procedure

Risk of Personal Injury. Do not attach air tools to open end of the hose until start-

up is completed and the unit checks okay.

Risk of Personal Injury. Never disconnect threaded joints with pressure in tank!

1. Check oil level per the Lubrication Section of this

manual.

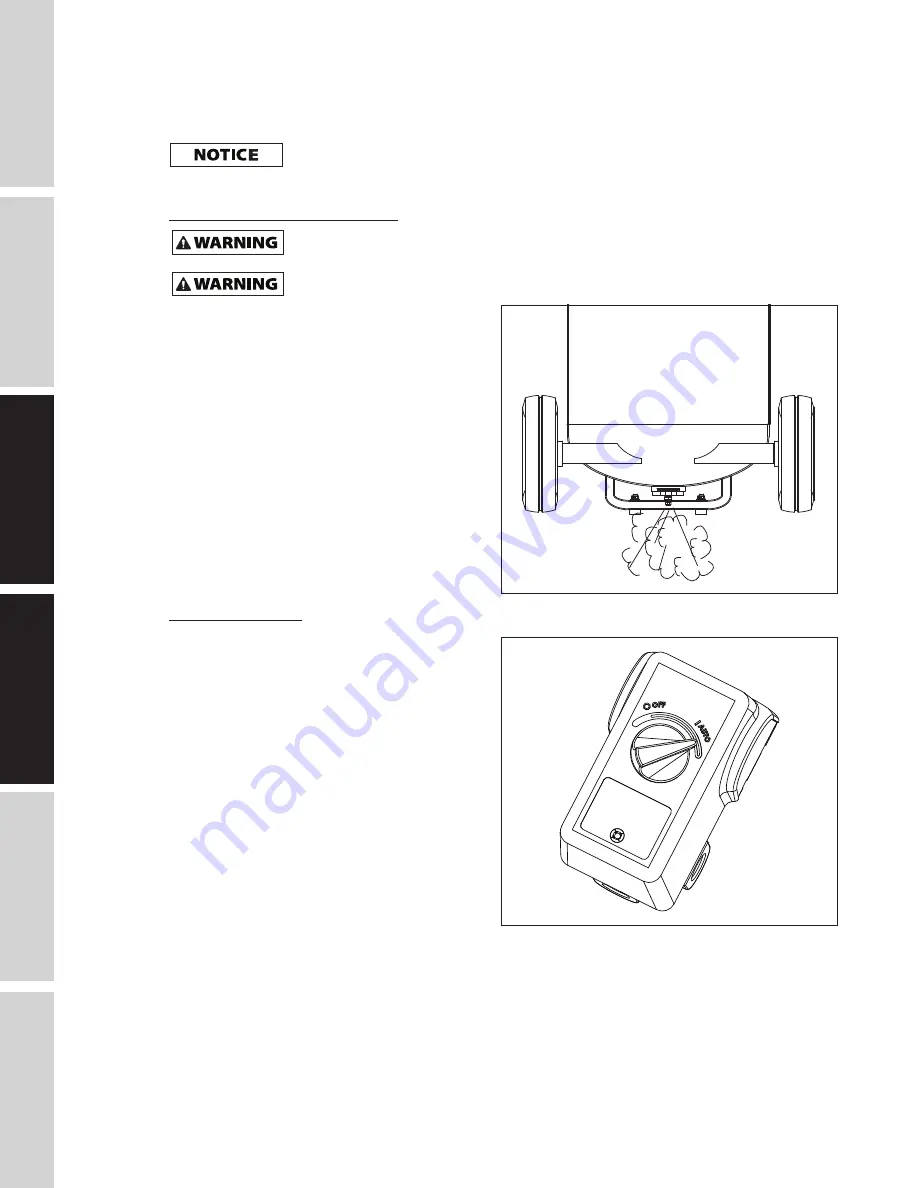

2. Open the bottom tank drain valve (see Figure 5).

Turn outlet valve to open air flow.

3. Plug unit in.

4. Move pressure switch to the

AUTO

position to run

the unit (see Figure 6).

5. Run the unit for thirty (30) minutes at zero (0) psi

(under no load) to break in pump parts.

6. Move the pressure switch lever or knob to

OFF

and turn tank drain valve to shut off air flow. The

compressor is now ready for use.

7. Change oil after first fifty (50) hours of operation.

Then perform oil changes every three (3) months.

Compressor Use

It is extremely important to operate the compressor in

a clean, well-ventilated area where the surrounding

air temperature will not be more than 100°F. Do not

locate the compressor air inlet near steam, paint spray,

sandblast areas or any other source of contamination.

Figure 5

Figure 6

Summary of Contents for FCT02C48V3X-A1X1XX

Page 67: ...NOTES NOTAS ...

Page 68: ...NOTES NOTAS ...