MAINTENANCE /

REP

AIR

TROUBLESHOOTING

OPERA

TION

SAFETY

/

SPECIFICA

TIONS

GETTING

ST

ARTED

10

ASSEMBL

Y

/

INST

ALLA

TION

INSTALLATION INSTRUCTIONS (CONTINUED)

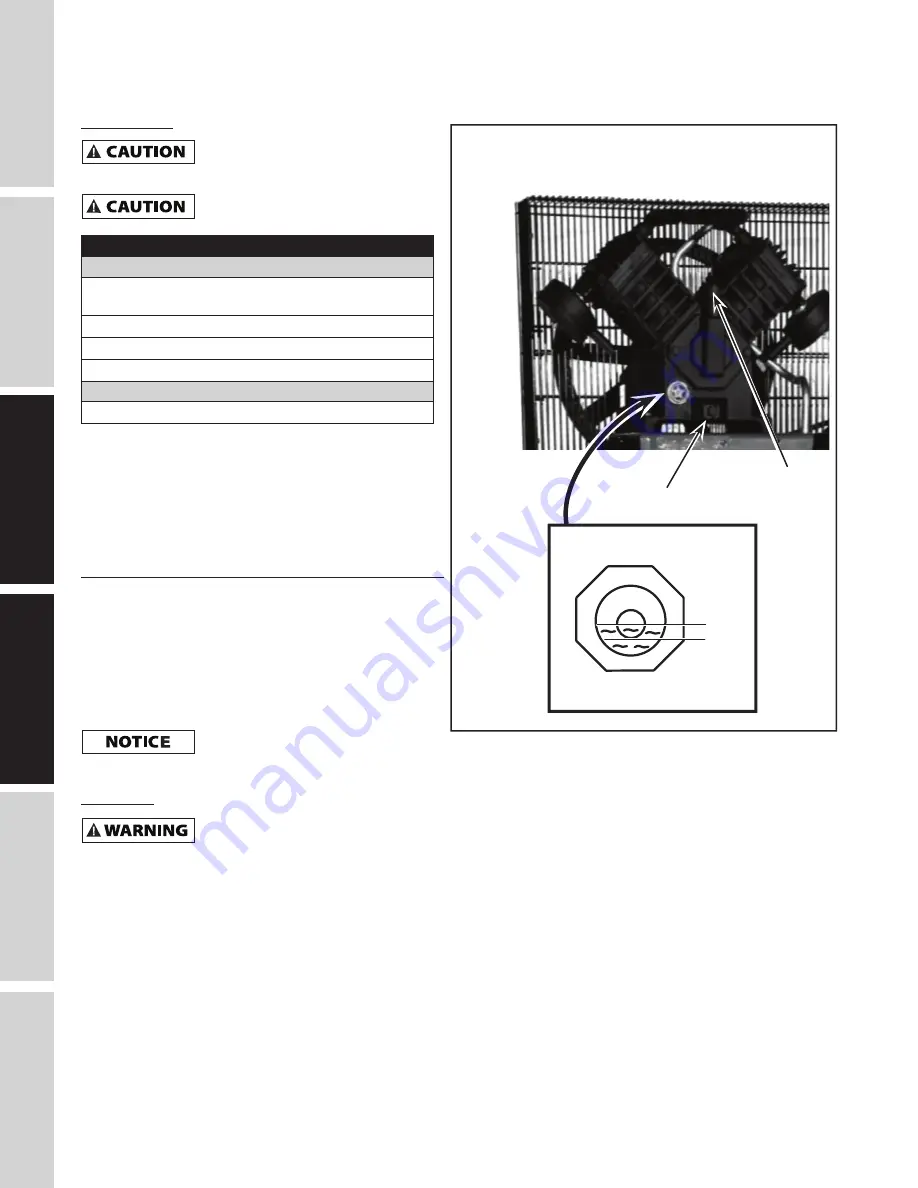

Lubrication

This unit contains no oil.

Before operating compressor, fill to the

center of the sight gauge (see Figure 6).

Using any other type of oil may

shorten pump life and damage valves.

QUICK REFERENCE

Recommended Oil (2 Options)

FSC-1000A ISO-100 Premium Reciprocating

Compressor Lubricant

12 quart case part number FSC-1000A-12

.

1 quart part number FSC-1000A-1

For generic option use 10W30

Oil Capacity

Approximately 40 oz.

Fill the pump with oil to the center of the sight gauge using oil

fill opening (see Figure 6).

Do NOT fill the pump through the

breather cap opening as this may cause oil to leak and spray

out during operation.

NOTE:

Some residual oil may still be in the pump from

factory testing leaving a thin coat on the sight gauge;

however, there is not enough oil to operate the unit.

OPERATING INSTRUCTIONS

IMPORTANT:

Check motor rotation before operating the

compressor.

All lubricated compressor pumps discharge some

condensed water and oil with the compressed air. Install

appropriate water/oil removal equipment and controls as

necessary for the intended application.

Failure to install appropriate

water/oil removal equipment may result

in damage to machinery or workpiece.

Guarding

The belt guard provided must be

installed before operating the unit.

All moving parts must be guarded. All electrical covers must be

installed before turning on the power.

Figure 6 - Lubrication

Oil Drain Plug

Oil Fill Plug

(behind breather)

Sight Gauge

Full

Low