10

Setup

Your work area should be kept between (15°C / 60°F) and (26°C / 80°F) to ensure consistent

prints. Be sure that the printer is on a level surface and away from direct sunlight. The UV

blocking yellow cover should prevent premature curing from daily lighting, but avoid long

exposure to strong artificial lighting or sunlight. Verify that your machine is clean and

undamaged.

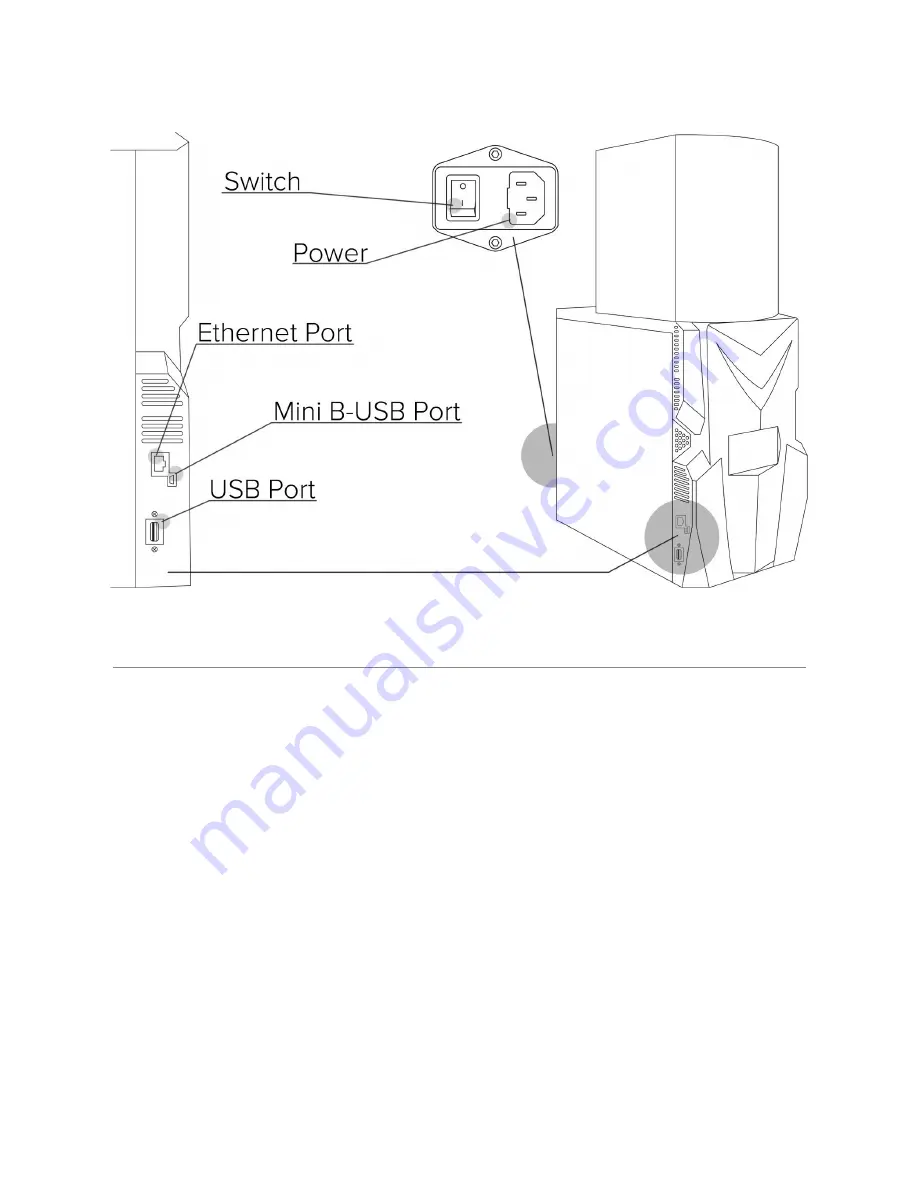

1. Choose your connection method and connect with the corresponding ports. Ethernet is

prefered, but USBPC connection, WiFi connection, and direct USB thumb drives are

also supported (Mini BUSB cable, Wifi dongle, and thumb drive not included).

2. Connect the female end of your power cable to the corresponding port in the rear of the

machine.

3. Flip the power switch to the on position.

4. The machine should boot within 90 seconds.

Summary of Contents for Phoenix Touch

Page 1: ...1 Main Menu ...

Page 8: ...8 Main Menu ...

Page 32: ...32 Main Menu ...

Page 42: ...42 Transport Information Not regulated for transportation Main Menu ...