10

Read the Manual

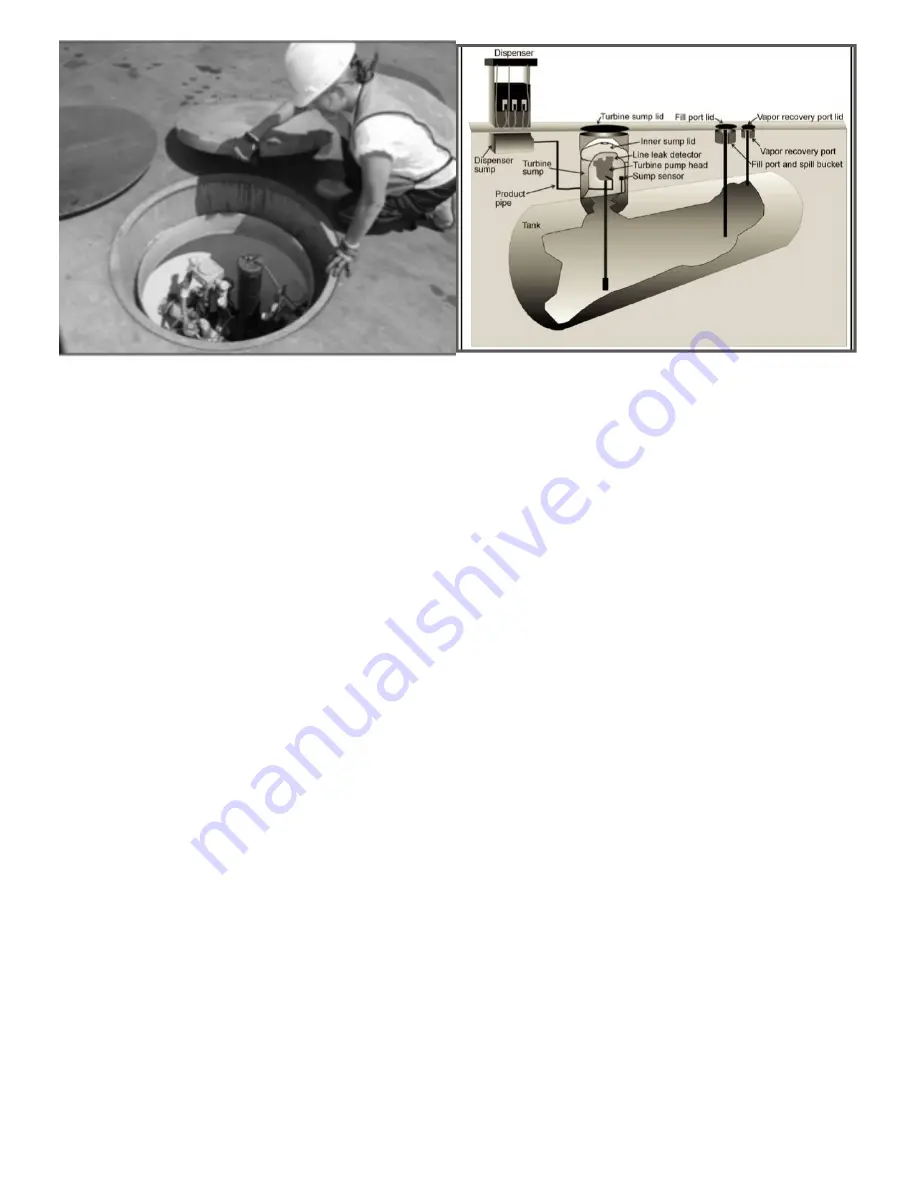

Removing Water Build up and contamination from

gasoline and ethanol blended fuel storage tanks with

Fueltec

’

s Model 955SS Fuel Polishing System

•

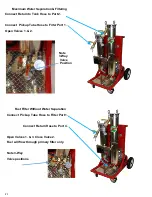

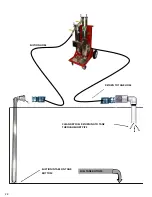

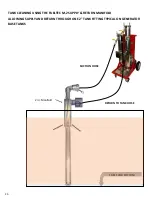

In operation the system pulls fluid from the fuel tank bottom by a vacuum created by the fuel

pump.

•

A bag type filter is first to remove sludge and solid contaminates from the tank bottom fluid which

may also contain water.

•

The fuel/water mix leaves the fuel pump under pressure

( do not exceed 60 PSI)

and is forced

through a filter/ coalescer where the tiny water droplets are made larger and separate from the

fuel.

•

The Teflon separator prevents the water droplets from traveling with the fuel. The water falls to

the bottom of the water trap.

•

A clear sight tube allows you to see the level of the water that has been separated.

•

With the system running; you can open a valve and send the water to a waste container

and the clean fuel back to the fuel storage tank.

•

The water level in the sight tube stops rising when all of the water has been vacuumed and sepa-

rated from the fuel storage tank.

•

Tank Cleaning is Done With No Loss of Product

•

A static ground is provided to dissipate static electric build up while pumping fuel.

•

One (1) micron bag filters should be used with Gasoline & ethanol blended fuels