– 11 –

7-4

Self-tuning Control

Self-tuning Control is a control which automatically calculate the value of PID, under the condi-

tion that the control target or set value (SV) changes.

Self-tuning is especially effective for situations when a high level of control is not needed, but

auto-tuning cannot be run due to frequent changes in the control target conditions.

Conditions where self-tuning can be used

Self-tuning is used in the following situations:

•

When temperature rises when the power is turned on

•

When temperature rises when SV changes (or when the controller decides it is necessary)

•

When the controller decides it is necessary because the controls have become unstable

Conditions where self-tuning cannot be used

Self-tuning cannot be used in the following situations:

•

During control standby

•

During ON/OFF (2-position) control

•

During auto-tuning

•

During ramp soak progress

•

When there is error input

•

When set for dual output

•

When any of the P, I, D, Ar parameters are set to manual

•

During manual mode

•

During soft start progress

Conditions to halt self-tuning

Halt self-tuning in the following situations:

•

When there is a change in SV (This includes the case where SV changes because of the

ramp soak function, remote SV function, or ramp SV.)

•

When self-tuning has not finished after running for nine or more hours

Setting self-tuning

7-5

PID2 Control

In case which the power supply of the control target goes ON

→

OFF

→

ON, this PID2 control

can suppress the amount of overshoot.

This control introduces an algorithm to prevent the calculated PID result from becoming a mis-

calculation, even when the control loop is open.

You will need to run auto-tuning to set the Pid parameter when using Pid2 control.

●

Features of PID2 Control

Setting PID2 control

7-6

Auto-tuning

Run auto-tuning to set the PID parameter automatically.

●

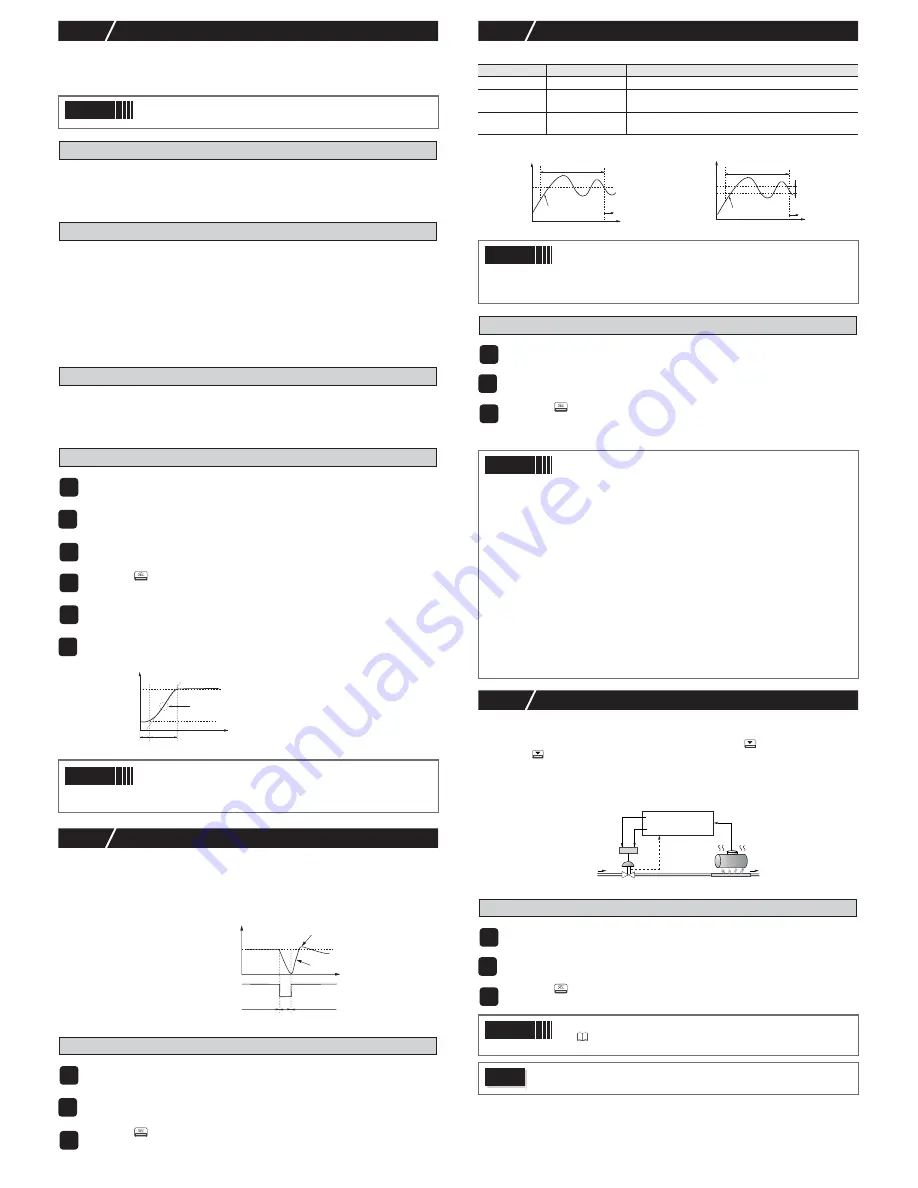

Normal type

●

Low PV type

Running auto-tuning

7-7

Valve Control (Servo Control 1 / Serve Control 2)

Valve controls adjust and control the valve position according to [OPEN] and [CLOSE] of the

contact signal.

Turn on the contact outputs in manual mode, so that pressing the

key means "OPEN", and

pressing the

key means "CLOSE"

Servo control 1 and servo control 2 have the following differences.

•

Servo Control 1: No valve position display

•

Servo Control 2: Has valve position display

Neither control can be used to control the valve position itself.

Setting Servo Control 1 or Servo Control 2

Point

When a high level of control is required, choose PID control, fuzzy PID

control, or PID2 control.

1

Turn on power of the controller and set the SV.

2

Display the system menu ("

SYS [h

7

").

3

Display the controller parameter ("

[trL

") and choose self-tuning ("

SELF

").

4

Press the

key to set the value.

5

Turn off power of the controller.

6

Turn on power of the control target equipment and the controller. Turn on

power of the control equipment first.

Self-tuning will begin.

Point

•

The equipment will not tune correctly if power of the controller is

turned on first.

•

To reset self-tuning, set the control method to PID ("PiD") once

before changing back to self-tuning.

1

Display the system menu ("

SYS Ch 7

").

2

Display the control parameter ("

CTrL

") and choose PID2 ("

Pid2

").

3

Press the

key to set the value.

dead time

t

process value

tuning

SV

lag time

suppress overshoot

ON

OFF

control equipment power

t

SV

process value

control loop

close

close

open

PV

"

At

" set value

Behavior

Function

"

oFF

"

Stop/Finish

Stops or finishes auto-tuning.

"

on

"

Normal type

The standard auto-tuning for SV reference. Choose this

auto-tuning in most situations.

"

Lo

"

Low PV type

Auto-tuning for SV-10% reference. Choose this when you

want to suppress the overshoot when tuning.

Point

Set the following parameters before running auto-tuning.

•

PV input type / PV input upper limit / PV input lower limit / Decimal

position / PV input filter in the setup channel menu ("

SET Ch

6

")

•

OUT1 proportion cycle (OUT2 proportion cycle) in the PID channel

menu ("

Pid Ch 2

").

1

Display the operation menu ("

oPE [h 1

").

2

Display auto-tuning ("

At

") and choose the tuning type.

Choose the standard type ("

on

") or low PV type ("

Lo

") according to the control target.

3

Press the

key to start auto-tuning.

A decimal point will blink at the bottom of the display during auto-tuning.

When auto-tuning has successfully competed, blinking decimal point will turn off and

overwrites the PID.

Point

•

PID parameter which is set after auto tuning has finished normally

will be maintained even when the power is turned off. However, the

PID value will not be changed if the power is turned off during auto-

tuning. In this case, rerun auto-tuning.

•

The equipment will use ON/OFF (2 position) control during auto-

tuning, so there may be a large change in PV according to the pro-

cess. Do not use auto-tuning for processes that do not permit a

large change in PV. Do not use auto-tuning for processes such as

pressure control and flow control that have a fast response.

•

Auto-tuning is not behaving normally if it has not finished after four

or more hours have passed. In these cases, recheck parameters

such as input/output wiring, control output behavior (normal/

reverse), and input sensor type.

•

Rerun auto-tuning if there is a large change in SV, a change in the

PV input type, or a change in the control target conditions that

reduces the effectiveness of the controls.

•

You can run auto-tuning when the control type is set to "fuzzy" or "PID2".

•

You cannot run auto-tuning in manual mode.

•

When using the PID selection function, the auto-tuning result for

the selected PID group is stored.

•

Auto tuning is forcibly terminated when SV changes because of

the ramp soak function, remote SV function, or ramp SV.

1

Display the system menu ("

SYS Ch 7

").

2

Display the control parameter ("

PrCS

") and choose servo control 1 ("

Srv1

").

This chooses "Servo Control 1".

3

Press the

key to set the value.

Point

•

Adjustments must be made to display the valve opening position.

"7-8 Position Feedback Control (PFB Control) (page 12)

•

An interlock function is built in.

Caution

Chattering may occur if the dead band ("

PGAP

") in the PFB menu ("

PFB Ch10

")

is set too small.

PV

t

process value AT start

AT calculating

PID control

SV

PV

t

process value AT start

AT calculating

PID control

SV

SV-10%FS

Valve

OPEN contact output

CLOSE contact output

Valve opening

(servo 2/PFB)

set value input

(temperature)

boiler

Valve motor

(servo 1)