– 16 –

Use the following steps to set soft start output set value and set time.

2. Error output function

When the error output specification function has concluded that the equipment has an error, it

halts the temperature controls and maintains the control output at a previously specified value.

There is an error in PV if any of the following conditions occur:

burnout upper limit / burnout lower limit / underage (PV< -5% FS) / overage (105% <PV)

Use the following steps to set this function.

3. Standby output function

Sets the control output value, alarm output, re-transmission output (ON/OFF), and PV/SV dis-

play for standby mode.

Use the following steps to set this function.

4. Ramp SV function

The ramp SV function suppresses a sudden change in SV (step change) when changing SV.It

allows SV to change smoothly according to the set slope of temperature per unit of time.This

smooth SV change allows you to minimize the effect of the change on controls.

You can set both inclining temperature and declining temperature slopes, and choose from

"minutes" or "hours" for the time units.

You can also choose for the SV display to show the current value or the target value during

ramp SV.

The SV lamp will blink while ramp SV is running.(When not displaying parameters or Ch.)

When you turn on the power while ramp SV is in effect, ramp SV will begin using the starting

value of PV (PV start).

Use the following steps to set ramp SV.

5. SV selection function

The SV selection function can record and switch up to eight sets of SV information to the pal-

ette menu settings. It is effective when the SV used during a process are numerous and the

set values have been previously decided.

Use the following steps to save SV information.

The following four methods can switch SV.

•

parameter “

SvN

” / press the user key / DI function / overwrite parameter “

SvN

” via the

communication function

●

Switch Using Parameter "

Svn

"

●

Switch Using the User Key

●

Switch Using DI Function

●

Switch Using Parameter “

Svn

” via the Communication Function

Display

Parameter

Function

"

SFo1

" (SFo1)

MV1 soft start

output set value

Places a limit on MV1 output after power is turned on for a

time period set in SFTM.

"

SFTM

" (SFTM)

Soft start set time

Sets the time for soft start to function after turning power

on. Setting "0" will turn off soft start.

Caution

The soft start function cannot be used simultaneously with the valve control

functions, and cannot be used simultaneously with the dual control.

Point

During manual mode, the manual output value has priority, but soft start

will continue to keep track of the set time period.

1

Display the setup menu ("

SET [h 6

").

2

Display soft start output 1 ("

SFo1

") and set the output value.

3

Display soft start set time ("

SFTM

") and set the time.

4

Press the

key to set the value.

5

Turn off the power once, and then re-start the controller to begin soft start.

(When the soft start function is turned on, the lower display will alternate show-

ing SoFT and SV.)

Note: Do not use auto-tuning at the same time.

1

Display the setup menu ("

SET [h 6

").

2

Display FALT output 1 set value ("

FLo1

") and set the output value.

For dual control, set "

FLo2

" the same way.

3

Press the

key to set the value.

1

Display the setup menu ("

SEt [h 6

").

2

Display the standby mode setting ("

Sbmd

") and set the alarm output, re-trans-

mission output, and PV/SV display for standby mode.

Refer to

For the possible ON/OFF combinations for each output, see "6-6 Setup (Ch 6)"

(page 8).

3

Display the standby control output 1 set value ("

Sbo1

") and set the output value.

For dual control, set "

Sbo2

" the same way.

4

Press the

key to set the value.

t

control output (MV)

soft start

set time

soft start output

set value

MV when not using

soft start

MV when using

soft start (limited)

power on

0

%

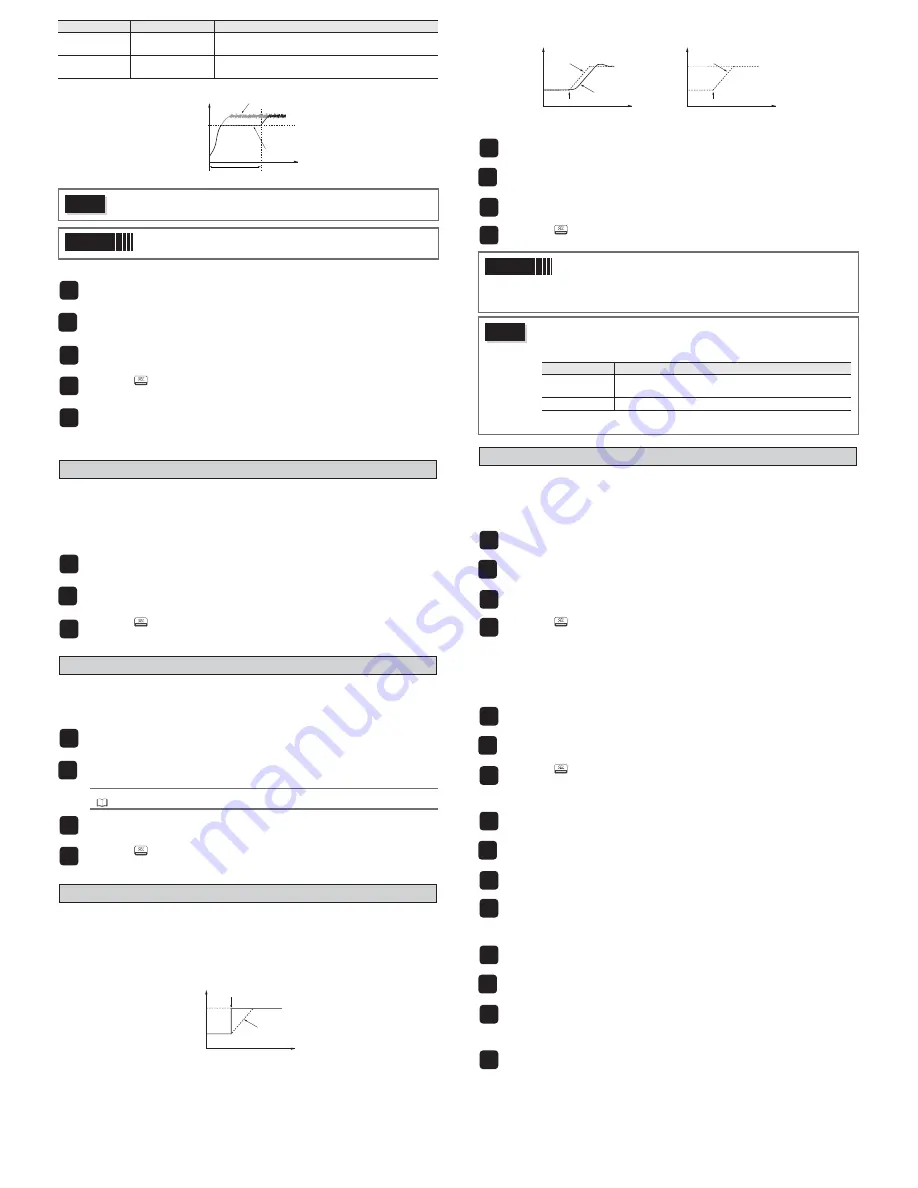

t

SV during ramp SV behavior

(rMPL/rMPH)

SV

changing SV with the front key

set value

after change

set value

before change

1

Display the system menu ("

SYS Ch 7

").

2

Set both ramp SV decline ("

rMPL

") and incline ("

rMPH

").

3

Set the unit of time for the slope ("

rMPU

") during ramp SV.

4

Press the

key to set the value.

Point

•

Ramp SV can be used with remote SV or SV selection functions.

•

Ramp SV cannot be used at the same time with ramp soak.

•

Coming out of a standby state will begin PV start.

•

Make sure to check the controller’s parameters after changing PV

scale.

Caution

If the power is turned on during the input error, or released standby, the ramp

SV operates differently from the normal PV start.

1

Display the palette menu ("

PLt [h 3

").

2

Display SV setting 1 ("

SV1

") and set SV1.

3

Set SV setting 2 through SV setting 7 in the same way as necessary.

4

Press the

key to set the value.

1

Display the operation menu ("

oPE [h 1

").

2

Display the selected SV number ("

Svn

") and choose the SV No.

3

Press the

key to set the value.

1

Display the palette menu ("

PLT Ch 3

").

2

Display max selected SV number ("

SvMX

") and set the SV number by choosing it

with the user key.

3

Display the user key function setting ("

UKEy

") and set it to SV selection

function.

4

On the PV/SV display, pressing the user key will switch you from the currently

selected SV to the next SV.

1

Display the operation menu ("

oPE Ch 1

").

2

Display the selected SV number ("

Svn

") and choose "di".

3

Display the DI function setting ("

di1

" to "

di5

") and set the SV selection

function.

1

In the communication, overwrite the set value to the selected SV

number ("

Svn

").

t

PV

power ON

SV

SV

behavior when power rises

t

Sv switches to Sv-1 with DI input

SV

SV

Sv

Sv-1

behavior when SV changes with DI

State at PV start

Operation

Standby

PV tracking (Maintains the state where SV=PV. The SV ramp

function does not operate.)

Auto or manual

Starts the ramp SV from the current SV (PV start is off)