– 17 –

6. PID selection function

The SV selection function can record and switch up to eight sets of PID parameters from the

palette menu settings.

It is effective when the control equipment changes the target often and must frequently change

the PID parameters.

Use the following steps to save PID information.

The PID parameter selection (P, i, d, normal and reverse settings) can be changed by the

same four methods as the SV selection function.

●

Switch Using Parameter

"

PLn1

"

●

Switch Using the User Key

●

Switch Using DI Function

●

Switch Using Parameter "

PLn1

" via the Communication Channel

7. Startup mode function

The startup mode specification function sets the controller to start up in either auto mode ,

manual mode , remote mode or standby mode.

It is used when you want to start up in manual mode.

Use the following steps to set this function.

8. User function key

Pressing the

key in the monitor screen display, channel screen display, or parameter screen display

will immediately return you to the PV/SV display, regardless of assigned function.

Holding the

key down for about a second in PV/SV display or PV/MV display (only during

manual mode) will run the assigned function.The standard factory default for the

key is

switchover between auto and manual modes.

Use the following steps to set this function.

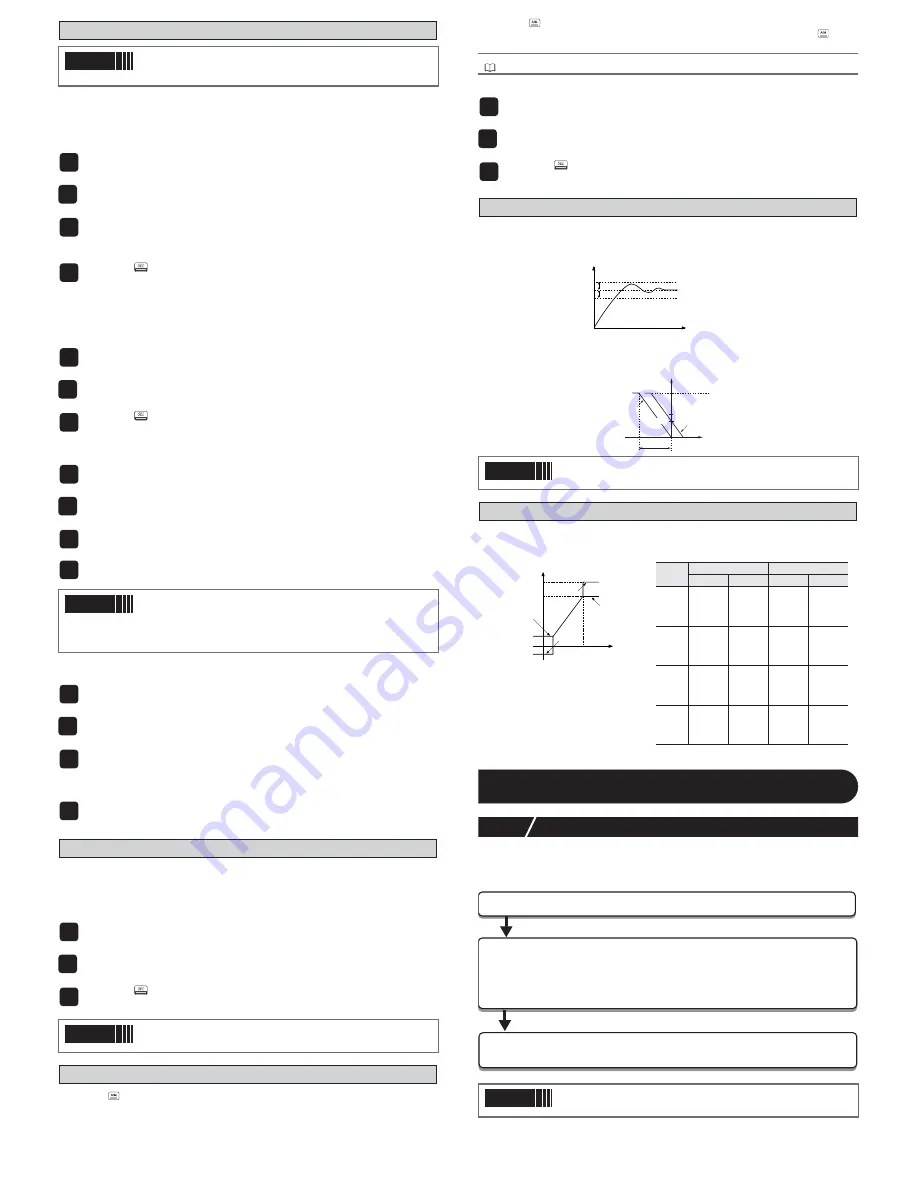

9. bAL and Ar functions

●

The anti-reset windup function ("

Ar

") cuts integration that falls outside of the Ar set range

that is centered around SV.

Running auto-tuning will set the optimum values for P, i, and d parameters, as well as Ar.

●

The output convergence value function ("

bAL

") outputs to PV and SV a calculated result of

the PID computed MV plus the bAL offset.

(The factory setting of bAL is 0% for single output, 50% for dual output.)

10. MV limit function

The MV limit function allows you to choose whether to limit the MV or let it pass through maxi-

mum and minimum MV.

8

Setting the Temperature Controller

8-1

Input Setting

Set the type and the range for input sensor.

Input can be set in the setup menu ("

SET [h6

").

For more on input types, input scaling, decimal point location, and input codes, see "10 Input

Range and Codes (standard renge)". (page 18)

Point

When switching the normal and reverse operation by using the PID selec-

tion function, be sure to turn off the system power beforehand for safety

reasons (Do not switch normal and reverse operation during control).

1

Display the palette menu ("

PLT Ch 3

").

2

Display proportional bandwidth setting 1 ("

P1

") and set P1.

3

Set "i1" and "d1" in the same way.

Set the following parameters as necessary: ON/OFF control hysteresis ("

hyS1

"), cool-

ing proportional band ("

CoL1

"), dead band ("

db1

"), balance ("

bAL1

"), anti-reset windup

("

Ar1

"), and normal/reverse setting ("

rEv1

").

4

Press the

key to set the value.

1

Display the operation menu ("

oPE Ch1

").

2

Display the selected PID number ("

PLn1

") and choose the PID No.

3

Press the

key to set the value.

1

Display the palette menu ("

PLT Ch 3

").

2

Display max selected PID number ("

PL1M

") and set the PID number by choosing

it with the user key.

3

Display the user key function setting ("

UKEy

") and set it to PID selection

function.

4

On the PV/SV display, pressing the user key will switch you from the currently

selected PID to the next PID.

Point

When the user key function code is 27 (SV No.+1, PID No.+1 (send))

and the initial PID No. and SV No. are different, the first time you press

the user key, PID No. will become the same as SV No.

Also the SVMX parameter value becomes the maximum selectable

number for PID No. and SV No.

1

Display the operation menu ("

oPE Ch 1

").

2

Display the selected PID number ("

PLn1

") and choose "di".

3

Display the DI function setting ("

di1

" to "

di5

") and set the PID selection

function.

1

In the communication, overwrite the set value for the selected PID number

("

PLn1

").

1

Display the system menu ("

SYS [h 7

").

2

Display the startup mode ("

Stmd

") and choose the operational mode.

Choose from auto or manual.

3

Press the

key to set the value.

After changing the above setting, restarting the controller will start it in the selected

mode.

Point

When starting up in manual, the MV becomes 0%.

Refer to

For functions that can be assigned, see "6-7 System (Ch7)" (page 8).

1

Display the system menu ("

SYS [h 7

").

2

Display the assign user key specification ("

UtEy

") and choose the function.

3

Press the

key to set the value.

Point

Ar1 to Ar7 and bAL1 to bAL7 have the same function as in each PID

group.

Point

PV scaling and decimal point location can be used with the factory

settings.

PV

SV

}

}

}

cuts integration

includes integration

cuts integration

PV

AR value

AR value

proportional

bandwidth

MV

bAL=40%

50%

PV

SV

40%

bAL=0

%

100%

PHC

PLC

103%

output value

(before limit)

PHC

PLC

limit

pass

limit

pass

—3%

output value

(after limit)

PCUT

MV1

MV2

PHC1

PLC1

PHC2

PLC2

"

0

"

"

1

"

"

2

"

"

3

"

103%

103%

limit

limit

-3%

limit

-3%

limit

103%

103%

103%

103%

-3%

-3%

-3%

-3%

"

4

"

"

5

"

"

6

"

"

7

"

103%

103%

limit

limit

-3%

limit

-3%

limit

103%

103%

103%

103%

limit

limit

limit

limit

"

8

"

"

9

"

"

10

"

"

11

"

103%

103%

limit

limit

-3%

limit

-3%

limit

limit

limit

limit

limit

-3%

-3%

-3%

-3%

"

12

"

"

13

"

"

14

"

"

15

"

103%

103%

limit

limit

-3%

limit

-3%

limit

limit

limit

limit

limit

limit

limit

limit

limit

1.

Choose an input type ("

PVt

")

Check the type of the thermocouple or resistance bulb which is used.

2.

Set the PV scaling (input range) ("

PVb

"/"

PvF

")

Set Pvb to the lower limit of the temperature range and PvF to the upper limit. It is recom-

mended to set the values at the standard range, even though they can be set at values

beyond of it.

There is no standard range for DC voltage or DC current input. (-1999 to 9999, lower

limit<upper limit)

3.

Set the decimal point location ("

Pvd

")

Sets whether or not to display digits after the decimal point. Two digits can also be dis-

played after the decimal point when using 1 to 5V DC, and 4 to 20mA DC.