– 7 –

6-3

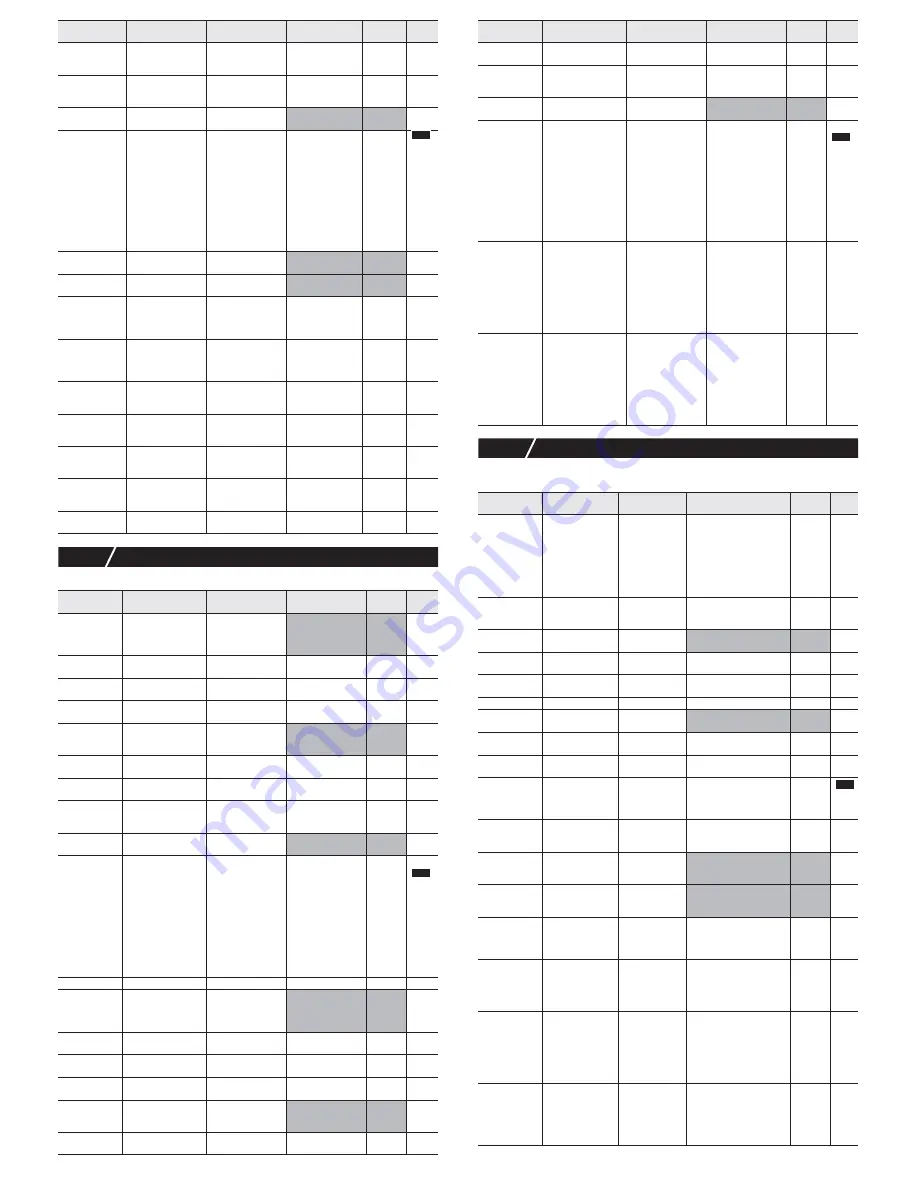

PID Palette (Ch3)

Saves the palette values of PV and PID. Up to seven sets can be saved.

6-4

Ramp soak (Ch4)

Create a pattern of temperatures using ramp soak combinations. You can create a temperature

pattern with up to 16 steps.

"

db

" (db)

Dead band

Shifts the cooling

proportional band

from the set value

-50 to 50%

0%

(Note4)

"

bAL

" (bAL)

Output

convergence value

Offset value which

is added to the MV

output value

-100 to 100%

0/50

(single/

dual)

"

Ar

" (Ar)

Anti-reset

windup

Sets the range of

integration control

0 to 100% FS

100%FS

"

rEv

" (rEv)

Sets normal/

reverse operations

Sets the control

action

rv-- (heat (reverse)

/cool (none))

no-- (heat (normal)

/cool (none))

rvno (heat (reverse)

/cool (normal))

norv (heat (normal)

/cool (reverse))

rvrv (heat (reverse)

/cool (reverse))

nono (heat (normal)

/cool (normal))

rv--/rvno

(single/

dual)

"

SvL

" (SvL)

SV limit

(lower limit)

Sets the lower limit

of SV

0 to 100% FS

0% FS

(Note5)

"

Svh

" (Svh)

SV limit

(upper limit)

Sets the upper

limit of SV

0 to 100% FS

100% FS

(Note5)

"

t[1

" (TC1)

OUT1 proportion

cycle

Sets the proportion

cycle of the control

output (OUT1)

(contacts, SSR drive)

1 to 150 sec

30:

Contact

2: SSR

drive

(Note7)

"

t[2

" (TC2)

OUT2 proportion

cycle

Sets the proportion

cycle of the control

output (OUT2)

(contacts, SSR drive)

1 to 150 sec

30:

Contact

2: SSR

drive

(Note4)

"

Plc1

" (PLC1)

OUT1 lower limit

Sets the lower limit

of the control output

(OUT1)

-3.0 to 103.0%

-3.0%

"

Ph[1

" (PhC1)

OUT1 upper limit

Sets the upper limit

of the control output

(OUT1)

-3.0 to 103.0%

103.0%

"

PL[2

" (PLC2)

OUT2 lower limit

Sets the lower limit

of the control output

(OUT2)

-3.0 to 103.0%

-3.0%

(Note4)

"

Ph[2

" (PhC2)

OUT2 upper limit

Sets the upper limit

of the control output

(OUT2)

-3.0 to 103.0%

103.0%

(Note4)

"

P[UT

" (PCUT)

Selects the type of

output limiter

Sets the type of

output limiter

0 to 15

0

Parameter

display symbol

Parameter name

Function

Setting range

Initial

value.

Remarks

"

Sv1

" (Sv1)

SV 1

Sets the SV set

value

SV limit (lower)

(SVL) to

SV limit (upper)

(SVH) %FS

0%FS

(Note5)

"

P1

" (P1)

Proportional band 1

Sets the

proportional band

0.0 to 999.9%

5.0%

"

i1

" (i1)

Integration time 1

Sets the

integration time

0 to 3200 sec

240 sec

"

d1

" (d1)

Differential time 1

Sets the

differential time.

0.0 to 999.9 sec

60.0 sec

"

hyS1

" (hyS1)

ON/OFF control

hysteresis 1

Sets the hysteresis

when using the

ON/OFF control.

0 to 50% FS

1 °C

"

[oL1

" (CoL1)

Cooling proportional

band 1

Sets the cooling

proportional band

0.0 to 100.0

1.0

(Note4)

"

db1

" (db1)

Dead band 1

Sets the dead

band

-50.0 to 50.0%

0%

(Note4)

"

bAL1

" (bAL1)

Output convergence

value 1

Offset value which

is added to the

control output

-100.0 to 100.0%

0/50

(single/

dual)

"

Ar1

" (Ar1)

Anti-reset windup 1

Sets the anti-reset

windup

0 to 100% FS

100%FS

"

rEv1

" (rEv1)

Sets normal/

reverse 1

Sets the control

action

rv-- (heat (reverse)/

cool (none))

no-- (heat (normal)/

cool (none))

rvno (heat (reverse)/

cool (normal))

norv (heat (normal)/

cool (reverse))

rvrv (heat (reverse)/

cool (reverse))

nono (heat (normal)/

cool (normal))

rv--/rvno

(single/

dual)

(Note6)

"

Sv7

" (Sv7)

SV 7

Sets the SV set

value

SV limit (lower)

(SVL) to

SV limit (upper)

(SVH) %FS

0%FS

(Note5)

"

P7

" (P7)

Proportional band 7

Sets the

proportional band

0.0 to 999.9%

5.0%

"

i7

" (i7)

Integration time 7

Sets the

integration time

0 to 3200 sec

240 sec

"

d7

" (d7)

Differential time 7

Sets the

differential time.

0.0 to 999.9 sec

60.0 sec

"

hyS7

" (hyS7)

ON/OFF control

hysteresis 7

Sets the hysteresis

when using the

ON/OFF control.

0 to 50% FS

1 °C

"

[oL7

" (CoL7)

Cooling proportional

band 7

Sets the cooling

proportional band

0.0 to 100.0

1.0

(Note4)

Parameter

display symbol

Parameter name

Function

Setting range

Initial

value

Remarks

RST

RST

…

…

…

…

…

…

"

db7

" (db7)

Dead band 7

Sets the dead

band

-50.0 to 50.0%

0%

(Note4)

"

bAL7

" (bAL7)

Output convergence

value 7

Offset value which

is added to the

control output

-100.0 to 100.0%

0/50

(single/

dual)

"

Ar7

" (Ar7)

Anti-reset windup 7

Sets the anti-reset

windup

0 to 100% FS

100% FS

"

rEv7

" (rEv7)

Sets normal/reverse

7

Sets the control

action

rv-- (heat (reverse)

/cool (none))

no--(heat (normal)

/cool (none))

rvno (heat (reverse)

/cool (normal))

norv (heat (normal)

/cool (reverse))

rvrv (heat (reverse)

/cool (reverse))

nono (heat (normal)

/cool (normal))

rv--/rvno

(single/

dual)

(Note6)

"

SvMX

" (SvMX)

Sets the Max SV

selection number

Choosing SV with

the user key sets it

to the maximum

possible number.

Sv0

Sv1

Sv2

Sv3

Sv4

Sv5

Sv6

Sv7

di

Sv7

"

PL1m

" (PL1M)

Set the Max PID

selection number

Choosing PID with

the user key sets it

to the maximum

possible number.

Pid0

Pid1

Pid2

Pid3

Pid4

Pid5

Pid6

Pid7

di

P

id

7

Parameter

display symbol

Parameter name

Function

Setting range

Initial

value

Remarks

"

Ptn

" (PTn)

Ramp soak

operation pattern

(Step No.)

Sets which

steps to use in

the ramp soak

operation

pattern

0 (uses steps 1 to 4)

1 (uses steps 5 to 8)

2 (uses steps 1 to 8)

3 (uses steps 9 to 12)

4 (uses steps 13 to 16)

5 (uses steps 9 to 16)

6 (uses steps 1 to 16)

di (according to di)

6

(Note 21)

"

TiMU

" (TiMU)

Ramp soak time

units

Sets the units

of the ramp

soak time

hh.MM (hour:min)

MM.SS (min:sec)

hh.MM

"

Sv-1

"

(Sv-1)

Ramp soak 1 seg/

SV

Sets the SV

0 to 100% FS

0%FS

"

tm1r

" (TM1r)

Ramp soak 1 seg

ramp time

Sets the ramp

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

tm1S

" (TM1S)

Ramp soak 1 seg

soak time

Sets the soak

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

Sv16

"

(Sv16)

Ramp soak 16 seg/

SV

Sets the SV

0 to 100% FS

0%FS

"

t16r

"

(T16r")

Ramp soak 16

seg ramp time

Sets the ramp

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

t16S

" (T16S)

Ramp soak 16

seg soak time

Sets the soak

time

00.00 to 99.59 (hour:min/

min:sec)

00:00

(hour:min)

"

mod

" (Mod)

Ramp soak mode

Sets the

program

operation

method

0 to 15

0

"

Gsok

" (Gsok)

Guaranty soak

ON/OFF

Sets the

guaranty soak

ON or OFF

oFF (guaranty soak off)

on (guaranty soak on)

oFF

"

GS-L

"(GS-L)

Guaranty soak

band (lower)

Sets the lower

limit of guaranty

soak

0 to 50% FS

5°C

"

GS-h

"(GS-h)

Guaranty soak

band (upper)

Sets the upper

limit of guaranty

soak

0 to 50% FS

5°C

"

PvST

"

(

PvST)

PV start

Sets whether or

not to start

ramp soak with

PV.

oFF (PV start OFF)

on (PV start ON)

oFF

"

ConT

"(ConT)

Restore mode

Sets how to

restart when

the controller is

restored after a

power loss.

rES (Reset)

Con (Continue)

ini (Restart)

rES

(Note 20)

"

PTnM

" (PTnM)

Sets the Max

pattern selection

Choosing

pattern with the

user key sets it

to the

maximum

possible

number.

0 to 6,di

6

"

PMin

"(PMin)

Sets the Min

pattern selection

Choosing

pattern with the

user key sets it

to the minimum

possible

number.

0 to 6, di

0

Parameter

display symbol

Parameter name

Function

Setting range

Initial

value.

Remarks

RST

…

…

…

…

…

…

RST