1

INZ-TN5ZBAS-E

The gas extractor is used to sample a gas from a funnel and send it to a gas analyzer. As it is used under

very severe conditions, it must provide the following performance.

• Be usable at temperature of a sampling point.

• Have no property to cause reaction with a sample gas or act as a catalyst on it.

• Not be choked by dust, or easily replaceable or cleanable when choked.

• Cause no remarkable sampling delay.

Fuji Electric offers gas extractors meeting these requirements on the basis of long-accumulated experience.

This gas extractor has a variety of types such as those with Y-shaped or T-shaped sampling tube depend

-

ing on the application, and therefore the actual product may differ slightly from the content of this manual

depending on the customer’s required specification.

Please refer to the individually submitted manufacturing specifications for external drawings, specifications,

accessories, spare parts, and consumable parts.

1. outLinE

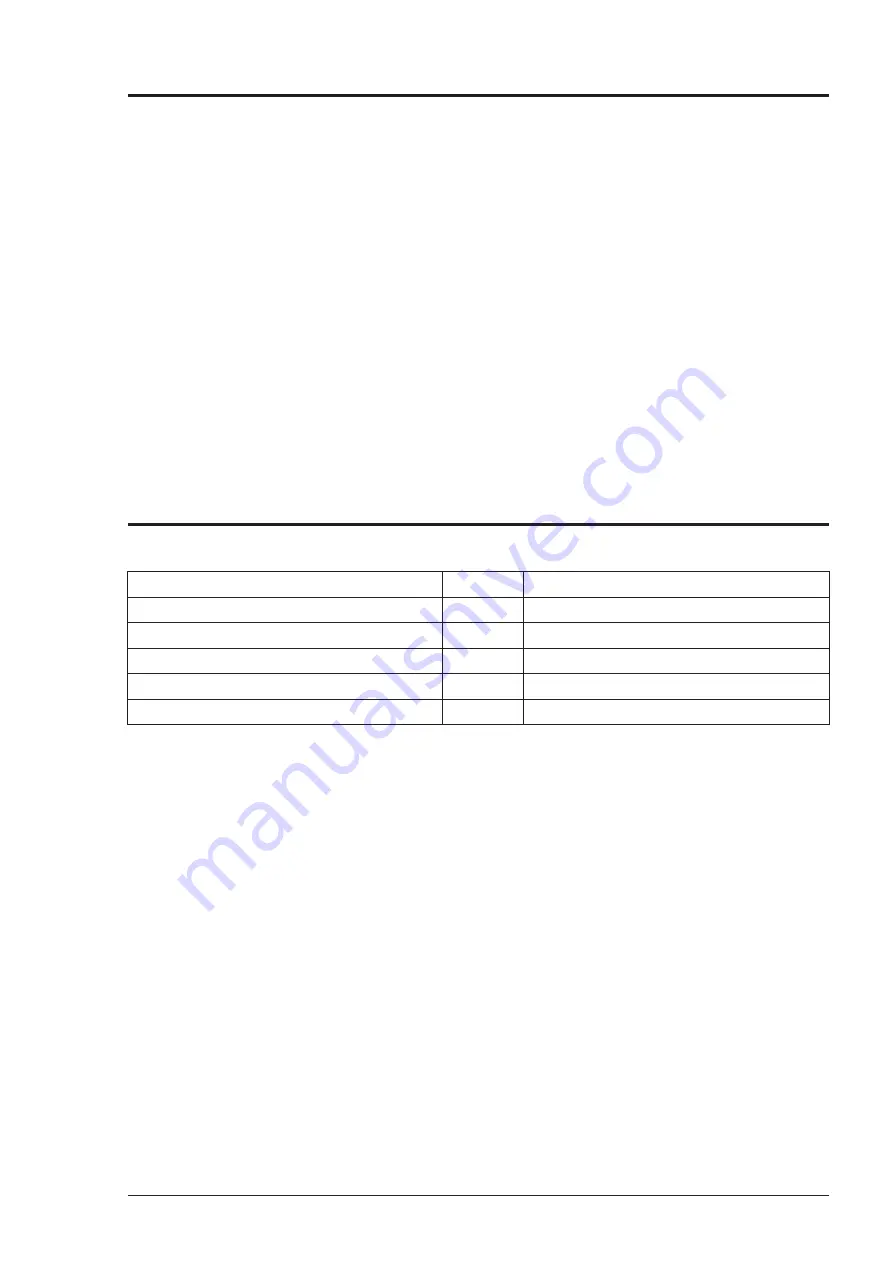

2. ConFiRMAtion oF DELiVERED PRoDuCts

Delivered products list

Name of product

Quantity

Remark

Gas extractor main unit

1

Sampling tube

1

As specified length

Packing (for flange)

1

Bolt, nut, spring washer, plane washer (M16)

4 each

When using standard flange JIS 10K50AFF

O-ring (G50, G65)

1 each