66

Reference Guide Optional Units

7.2

Curl correction

The curl correction button is used to correct paper curl caused by heat and/or pressure.

The curl correction button can be operated regardless of the machine state when the machine is ON.

Note

This curl correction function can be used during printing. Fine correction according to the paper

properties can be made from [Adjust Paper Curl].

Since staples are likely to be affected by curl, make sure to perform curl correction by checking the curl

direction of output paper.

When correction is performed while the machine is in operation, it is applied to the paper output

immediately after the button is pressed.

1.

Check the curl direction of paper.

2.

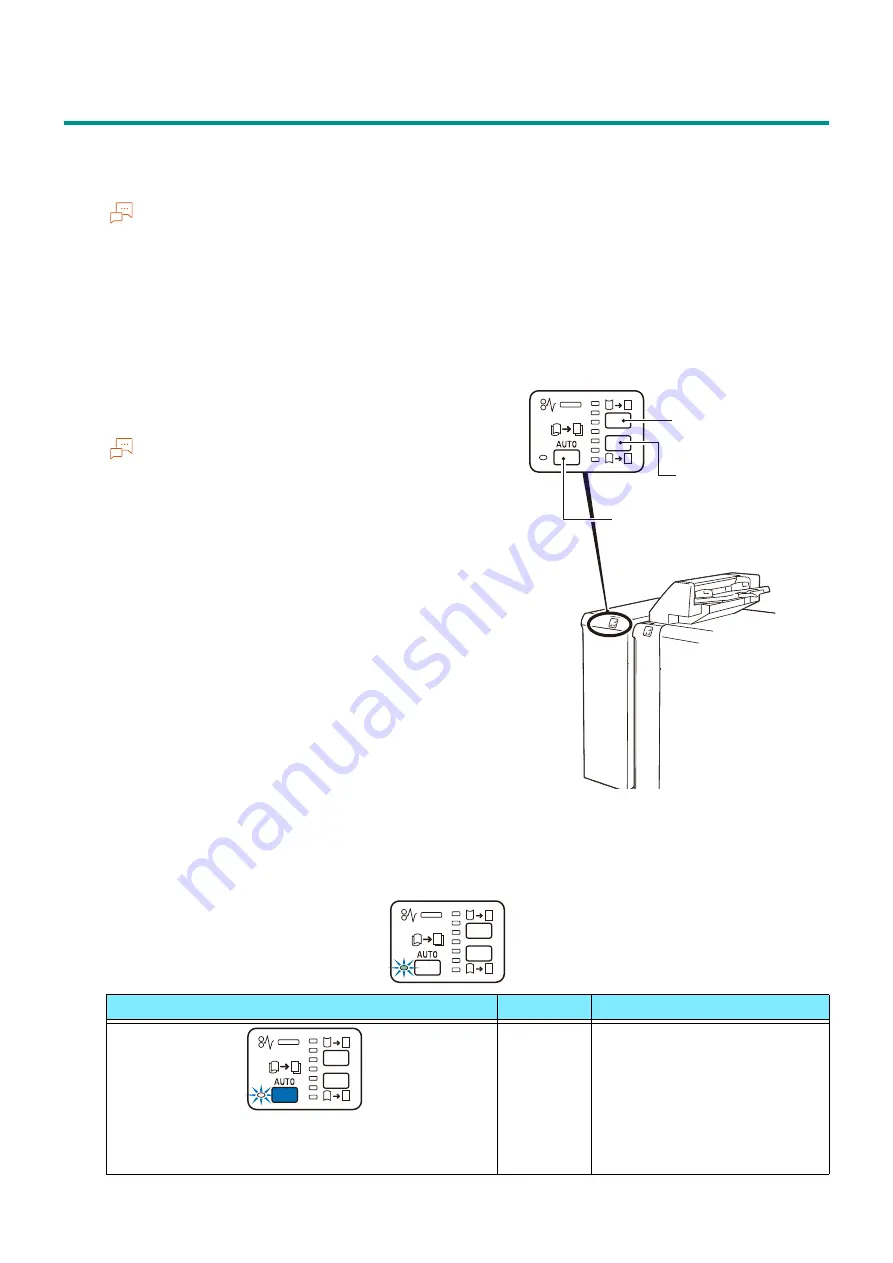

Confirm that the curl correction indicator is lit,

and then press the button.

Note

When paper is fed in the [AUTO] mode, the

indicator showing the present direction and

intensity of curl correction turns on only for a

brief moment. When manually applying the curl

correction, make adjustments while using this

indicator lighting as a guide.

After applying the curl correction by upward curl

correction button or downward curl correction

button, when feeding thick paper, embossed

paper, or OHP film, the [AUTO] is entered

automatically, and the curl correction is applied

using standard correction value.

You can also change to a setting that the mode

does not change to [AUTO] mode even when

using these paper types. For details, contact

your local representative.

Operations and Functions of Curl Correction

Press the AUTO button to enter the [AUTO] mode.

Indicator

Mode

Function

AUTO

Curl correction is automatically

performed.

It is recommended to use this

mode basically.

Optimum curl correction is

performed according to the

paper size and output

direction.

Downward

curl correction button

Upward curl

correction button

<AUTO> button