SS1807-N002

Failure Analysi

-

52/64

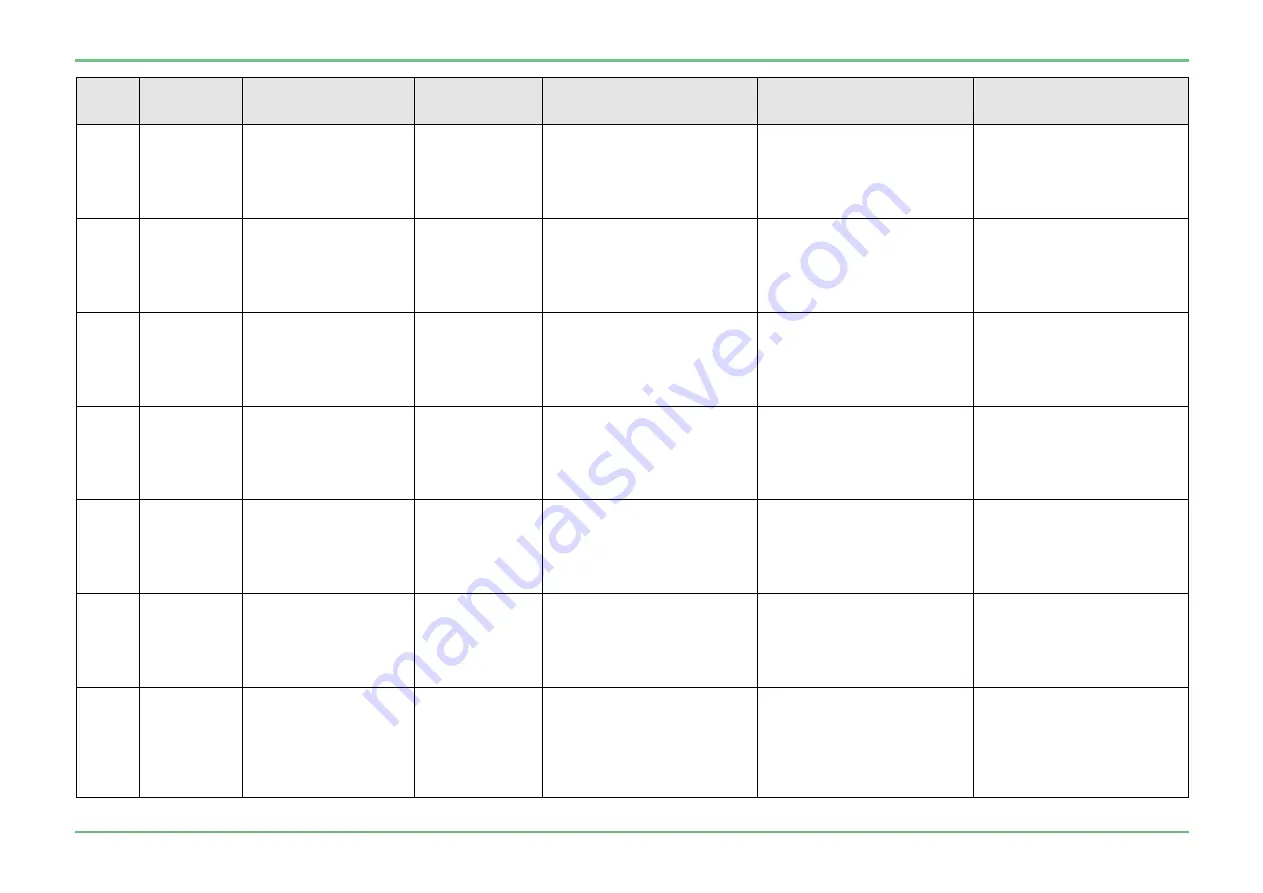

Display

error

code

Classification

level

Display message

(occurrence, response)

Display message

(guidance to

error)

Estimated cause

Trigger of message display

Service response

30153

Warning

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: PWM receiving error was

detected in light source.

The mode is shifted to manual

mode.

Automatically restored by

receiving PWM signals

At detection of disconnection of

PWM signals

Execute a reset.

Replace the interface cable.

Replace the light source if not

improved.

30154

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: FPGA version error was

detected in light source.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of FPGA data error

in LL-7000 light source

Execute a reset.

Upgrade the version of FPGA

(rewriting).

Replace the light source if not

improved.

30155

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: FPGA register readback

error was detected in light

source.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of FPGA data error

in LL-7000 light source

Execute a reset.

Upgrade the version of FPGA

(rewriting).

Replace the light source if not

improved.

30156

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: FPGA SPI

communication error was

detected in light source.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of FPGA

communication error in LL-7000

light source

Upgrade the version of FPGA

(rewriting).

Replace the light source if not

improved.

30157

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Cause: Writing error of EEPROM

initial value was detected in light

source.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of data error in light

source

Execute a reset.

If not improved, data is

determined to be corrupted.

30158

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

A/D converter with built-in CPU

was not responding.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of hardware error in

LL-7000 light source

Execute a reset.

Replace the light source if not

improved.

30159

Error

Unplug and plug back

endoscope, reset the

processor and the light

source.If the problem

persists, contact your

local FUJIFILM dealer.

Cause: The light

source LL-7000 is

in abnormal state.

Logical error (zero division,

overflow, etc.) occurred during

the operation of the CPU with

built-in light source.

Normal operation cannot be

guaranteed even though there is

no operation limit.

At detection of software error in

LL-7000 light source

Execute a reset.

Replace the light source if not

improved.

Summary of Contents for EP-6000

Page 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Page 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Page 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Page 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Page 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Page 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Page 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Page 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Page 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Page 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Page 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Page 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Page 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Page 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Page 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Page 377: ...SS1807 N002 Installation 1 68 Installation ...

Page 445: ...SS1807 N002 ...