SS1807-N002

Periodical Maintenance

-

7/15

3.2 Inspection Items

*1: Confirm only if used in medical institutions.

*2: As paper is consumed, confirm only if permission is obtained by the medical institution.

*3: Confirm with the scope used at the medical institution or the same model.

3.2.1 Appearance

No.

Inspection items

Inspection specification

How to inspect

Remarks

1

All sides of the

equipment

・

There is no crack, deformation or irregularity that

negatively impacts the function/performance.

・

There is no rust or taint that negatively impact the

function/performance of electrical connector.

・

There is no breakage, deformation on WC-LINK

cable terminal.

・

Each screw on the rear panel must be fully

tightened.

・

Check the appearance of front, rear, left/right

sides and top of the main unit.

・

Check the appearance of the electrical connector.

・

Check the appearance of the WC-LINK cable

terminal.

・

Touch and check each screw on the rear panel by

hand.

2

Specification plate

Caution label

・

The plate is adhered in the correct position.

・

The adhered label is correct.

・

Visually check the position of the plate and label,

and read the descriptions on them.

3

FOE

label

・

The label are adhered in the correct position.

・

The adhered label is correct.

・

Visually check the position of FOE label, and read

the description on it.

4

Silk printing

・

There is nothing lacking and skew on the printing.

・

Visually check the printing on the front and rear

panel.

・

Visually check the information mark.

5

Fuse

・

The T3.15A H250V fuse is mounted.

・

Remove the fuse to check the rated value.

3.2.2 Functions

No.

Inspection items

Inspection specification

How to inspect

Remarks

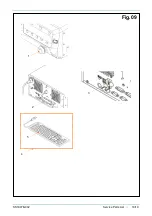

1

Dustproof Filter

・

There is not problem with attaching the dustproof

filter.

・

The filter is not clogged with dust or the like.

・

Remove the dustproof filter to check it.

2

Attach / detach the

electrical connector

・

The electrical connector can be smoothly

attached and detached.

・

Detach and attach the electrical connector to

check it.

Jig / Equipment

・

500 system scope or

600 system scope

Summary of Contents for EP-6000

Page 1: ...Processor EP 6000 FV693A Service Manual SR1807 N002 Ver 1 Oct 2018 ...

Page 5: ...SS1807 N002 General Table of Contents 1 1 General Table of Contents ...

Page 13: ...SS1807 N002 Caution in Safety 1 12 Caution in Safety ...

Page 25: ...SS1807 N002 Product Specifications 1 11 Product Specifications ...

Page 36: ...SS1807 N002 Instruction of System 1 106 Instruction of System ...

Page 133: ...SS1807 N002 Instruction of System 98 106 ELC PCB Patient PCB APC PCB APC PCB APC PCB DC Pump ...

Page 139: ...SS1807 N002 Instruction of System 104 106 9 4 Outline of PCB roles ...

Page 142: ...SS1807 N002 Failure Analysis 1 64 Failure Analysis ...

Page 206: ...SS1807 N002 Checkup Replacement and Adjustment 1 137 Checkup Replacement and Adjustment ...

Page 343: ...SS1807 N002 Service Parts List 1 19 Service Parts List ...

Page 352: ...SS1807 N002 Service Parts List 10 19 2 2 2 4 1 3 3 2 3 3 6 5 ...

Page 356: ...SS1807 N002 Service Parts List 14 19 1 3 3 4 1 2 1 3 X 4 1 3 3 4 3 3 ...

Page 358: ...SS1807 N002 Service Parts List 16 19 3 1 2 1 ...

Page 360: ...SS1807 N002 Service Parts List 18 19 Fig 09 5 4 2 3 1 ...

Page 362: ...SS1807 N002 Periodical Maintenance 1 15 Periodical Maintenance ...

Page 377: ...SS1807 N002 Installation 1 68 Installation ...

Page 445: ...SS1807 N002 ...