88

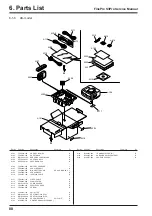

6. Parts List

FinePix S3Pro Service Manual

6-1-6. AS-model

Ref No.

Parts No.

Description

Comment

EL

Ref No.

Parts No.

Description

Comment

EL

A101

FZ06042-100

UNITARY BOX (W)

N

A102

FZ06012-100

SHEET MOLD

N

A103

BB12943-100

BAR CODE LABEL BLANK

N

A104

AZF0000-321

HDPE BAG NO.12

N

A105

AZF0000-101

LDPE BAG NO.10

N

A106

FZ06043-200

BATTERY CHARGER

=

A107

FZ06044-100

SHOULDER BELT

N

A108

FZ06040-300

NI-NH-BATTERY GN

HR AA GN BK 4S E =

A109

FZ05365-100

USB HARNESS

N

A110

FZ04797-100

IEEE1394 CABLE

N

A111

FZ03284-100

VIDEO CABLE

N

A112

FZ00363-200

CLAMP FILTER

N

A113

BB18148-100

CABLE HOLDER

N

A114

FZ04809-100

EYEPIECE COVER

N

A115

FZ05352-600

CD-ROM

N

A116

FZ06103-100

EMI FILTER

N

A117

BB18002-100

CERTIFICATION SEAL

N

A118

BB18385-600

DEST.LBL.5000AS J FG

N

A119

FZ05210-300

AC POWERCORD E

AC-5VW E

N

A120

BL00430-201

OWNER’S MANUAL S3PRO(ENG)

N

A

A

A111

A109

A119

A105

A113

A114

A116

A123

A122

A120

A121

A115

A104

A117

A103

A118

A101

A102

A108

A106

A107

A110

A112

A121

BL00431-200

I/F MANUAL S3PRO(W)

N

A122

BL00432-200

QUICKMANUAL S3PRO(ENG)

N

A123

BL00471-200

CAUTION E S3PRO

N

Summary of Contents for FinePix S3Pro

Page 27: ...27 3 Schematics FinePix S3Pro Service Manual 3 6 Circuit Diagrams 3 6 1 CCD BLOCK ...

Page 28: ...28 3 Schematics FinePix S3Pro Service Manual 3 6 2 DCDC BLOCK ...

Page 29: ...29 3 Schematics FinePix S3Pro Service Manual 3 6 3 IEEE1394 BLOCK ...

Page 30: ...30 3 Schematics FinePix S3Pro Service Manual 3 6 4 PROCESS BLOCK ...

Page 31: ...31 3 Schematics FinePix S3Pro Service Manual 3 6 5 CARD BLOCK 3 6 6 DCDC BLOCK CAMERA BODY ...

Page 32: ...32 3 Schematics FinePix S3Pro Service Manual 3 6 7 PARTNER CHIP BLOCK ...

Page 33: ...33 3 Schematics FinePix S3Pro Service Manual 3 6 8 PWON BLOCK ...

Page 34: ...34 3 Schematics FinePix S3Pro Service Manual 3 6 9 USB2 0 BLOCK ...

Page 35: ...35 3 Schematics FinePix S3Pro Service Manual 3 6 10 LCD BLOCK ...

Page 36: ...36 3 Schematics FinePix S3Pro Service Manual 3 6 11 SW BLOCK ...

Page 38: ...38 3 Schematics FinePix S3Pro Service Manual 3 7 2 MAIN PWB ASSY SIDE A ...

Page 39: ...39 3 Schematics FinePix S3Pro Service Manual SIDE B ...

Page 40: ...40 3 Schematics FinePix S3Pro Service Manual 3 7 3 SW PWB ASSY SIDE A SIDE B ...

Page 102: ...26 30 Nishiazabu 2 chome Minato ku Tokyo 106 8620 Japan FUJI PHOTO FILM CO LTD ...