FRC-200S-1

Safety Information -

安全に関する情報

read and understand these instructions before

performing any such task.

Our goal is to produce tools that help you work

safely and efficiently. The most important safety

device for this or any tool is YOU. Your care and

good judgment are the best protection against

injury. All possible hazards cannot be covered

here, but we have tried to highlight some of the

important ones.

Only qualified and trained operators

should install, adjust or use this power tool.

This tool and its accessories must not

be modified in any way.

Do not use this tool if it has been

damaged.

If the rated speed, operating pressure or

hazard warning signs on the tool cease to be

legible or become detached, replace without

delay.

For additional safety information consult:

Other documents and information packed with

this tool.

Your employer, union and / or trade association.

“Safety Code for Portable Air Tools” (ANSI

B186.1), available at the time of printing from

Global

Engineering

Documents

at

http://global.ihs.com/ , or call 1 800 854 7179. In

case of difficulty in obtaining ANSI standards,

contact ANSI via http://www.ansi.org/

Further occupational health and safety

information can be obtained from the following

web sites:

http://www.osha.gov (USA)

http://europe.osha.eu.int (Europe)

Air supply and connection hazards

Air under pressure can cause severe injury.

Always shut off air supply, drain hose of air

pressure and disconnect tool from air supply

when not in use, before changing accessories or

when making repairs.

Never direct air at yourself or anyone else.

Whipping hoses can cause severe injury. Always

check for damaged or loose hoses and fittings.

Do not use quick disconnect couplings at tool.

See instructions for correct set up.

Whenever universal twist couplings are used,

lock pins must be installed.

Do not exceed maximum air pressure of 6.3 bar /

90 psig / 0.63MPa, or as stated on tool nameplate.

Entanglement hazards

Keep away from rotating drive. Rotation may

continue for several seconds after the throttle

has been released. Do not lay the tool down

until rotation has stopped.

Choking, scalping and / or lacerations can

occur if loose clothing, gloves, jewellery, neck

ware and hair are not kept away from tool and

accessories.

You can be cut or burned if you come into

contact with the cutter, chips or work surface.

Avoid contact and wear suitable gloves to

protect hands.

Never stop a cutter by pressing on it.

Projectile hazards

Failure of the accessory or the workpiece can

generate high-velocity projectiles. Metal

cuttings and even small projectiles can injure

eyes and cause blindness.

Always wear impact-resistant eye and face

protection when involved with or near the

operation, repair or maintenance of the tool or

changing accessories on the tool.

Be sure all others in the area are wearing

impact-resistant eye and face protection.

Do not use cracked or deformed accessories.

Ensure the cutter is properly clamped using

the tools provided.

Ensure that sparks and metal cuttings are

directed so as not to cause a hazard.

Ensure that the workpiece is securely fixed.

Accessory hazards

Always shut off air supply, relieve hose of air

pressure and disconnect tool from air supply

when changing accessories.

Use only recommended sizes and types of

accessories and consumables.

Inspect the cutter before use. Do not use cutters

which may have been dropped or which are

chipped, cracked or otherwise defective.

Cutting edges are sharp and can become hot

during use. Avoid contact during and after use

and wear gloves to protect hands.

Summary of Contents for FRC-200S-1

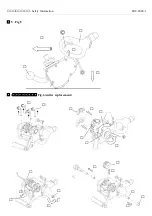

Page 4: ...Safety Information FRC 200S 1 5 Fig 5 6 Fig 6 cutter replacement...

Page 5: ......

Page 6: ...Safety Information FRC 200S 1 JA 6 EN Safety Information 10...

Page 9: ...FRC 200S 1 Safety Information...

Page 10: ...Safety Information FRC 200S 1 2 3 2 3 o D o E o E o 4 o D o A B o 5 o C o A B o o C o...

Page 12: ...Safety Information FRC 200S 1...