安全に関する情報

– Safety Information

FRC-200S-1

Operating hazards

Operators and maintenance personnel must be

physically able to handle the bulk, weight and

power of the tool.

Hold the tool correctly using both hands on the

handles: be ready to counteract sudden

movements.

Avoid injury by cutting or severing: avoid contact

with the cutter whenever the air supply is

connected to the tool. Wear protective equipment

such as gloves, apron and helmet.

Injury can be caused by uncontrolled movements

of the tool: always ensure that all of the base plate

is held firmly against the workpiece.

Cutting with these tools will create hot and sharp

edges on the workpiece. Wear gloves to protect

hands.

Always use sharp cutters.

Wait for the cutter to stop before setting the tool

down. An exposed rotating cutter may engage the

surface leading to possible loss of control and

serious injury.

Never force tool to cut faster or through heavier

gauge material than rated capacity.

Repetitive motion hazards

When using a power tool to perform work-related

activities, the operator might experience

discomfort in the hands, arms, shoulders, neck, or

other parts of the body.

Adopt a comfortable posture whilst maintaining

secure footing and avoiding awkward or off-

balance postures. Changing posture during

extended tasks can help avoid discomfort and

fatigue.

Do not ignore symptoms such as persistent or

recurring discomfort, pain, throbbing, aching,

tingling, numbness, burning sensation, or

stiffness. Stop using the tool, tell your employer

and consult a physician.

Noise and Vibration hazards

High sound levels can cause permanent hearing

loss and other problems such as tinnitus. Use

hearing protection as recommended by your

employer or occupational health and safety

regulations.

Exposure to vibration can cause disabling

damage to the nerves and blood supply of the

hands and arms. Wear warm clothing and keep

your hands warm and dry. If numbness, tingling,

pain or whitening of the skin occurs, stop using

tool, tell your employer and consult a physician.

Hold the tool in a light but safe grip because the

risk from vibration is generally greater when the

grip force is higher.

To prevent unnecessary increases in noise and

vibration levels:

Operate and maintain the tool, and select,

maintain and replace the accessories and

consumables, in accordance with this instruction

manual;

Use damping materials to prevent workpieces

from “ringing.”

Workplace hazards

Slip/Trip/Fall is a major cause of serious injury

or death. Be aware of excess hose left on the

walking or work surface.

Avoid inhaling dust or fumes or handling debris

from the work process which can cause ill health

(for example, cancer, birth defects, asthma

and/or dermatitis). Use dust extraction and wear

respiratory protective equipment when working

with materials which produce airborne particles.

Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contains chemicals known to the State

of California to cause cancer and birth defects or

other reproductive harm. Some examples of

these chemicals are:

Lead from lead-based paints

Crystalline silica bricks and cement and other

masonry products

Arsenic and chromium from chemically-

treated rubber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well-

ventilated area, and work with approved safety

equipment, such as dust masks that are specially

designed to filter out microscopic particles.

Proceed with care in unfamiliar surroundings.

Hidden hazards may exist, such as electric or

other utility lines.

This tool is not intended for use in potentially

explosive atmospheres and is not insulated from

coming into contact with electric power.

Summary of Contents for FRC-200S-1

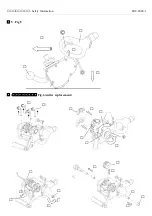

Page 4: ...Safety Information FRC 200S 1 5 Fig 5 6 Fig 6 cutter replacement...

Page 5: ......

Page 6: ...Safety Information FRC 200S 1 JA 6 EN Safety Information 10...

Page 9: ...FRC 200S 1 Safety Information...

Page 10: ...Safety Information FRC 200S 1 2 3 2 3 o D o E o E o 4 o D o A B o 5 o C o A B o o C o...

Page 12: ...Safety Information FRC 200S 1...