FRC-200S-1

Safety Information -

安全に関する情報

Protective equipment

Always wear necessary protective equipment such as

an eye protector, an ear protector, a face shield, a

safety apron, a helmet, gloves and other necessary

protective clothing. Use protective barriers where

necessary.

WARNING Risk of Property Damage or

Severe Injury

Ensure that you read, understand and follow all

instructions before operating the tool. Failure

to follow all the instructions may result in

electric shock, fire, property damage and/or

severe body injury.

►

Read all Safety Information delivered together

with the different parts of the system.

►

Read all Product Instructions for installation,

operation and maintenance of the different

parts of the system.

►

Read all locally legislated safety regulations

regarding the system and parts thereof.

►

Save all Safety Information and instructions

for future reference.

Statement of use

This product is designed for removing steel welding

beads.

No other use permitted. For professional use only.

Operation

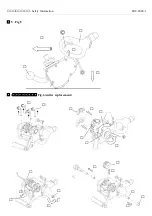

See figures on page 2,3.

Fix the accessories properly to the tool.

Use designated area for transportation to the

workpiece, see fig.2, to avoid unintentional start.

Connect device to a clean and dry air supply, with

suitable hose and connections according to fig.3.

To adjust cutter height,

o

turn the Lock Nut (D) counterclockwise

to unlock.

o

turn the Adjusting Handle (E) clockwise

to move the cutter up.

o

turn

the

Adjusting

Handle

(E)

counterclockwise to move the cutter

down.

o

adjust

the

cutting

depth

to

recommendation table fig.4.

o

turn the Lock Nut (D) clockwise to lock

cutter height.

To start operation,

o

Firmly hold the Main Handle (A) and the

Dead Handle (B).

o

Place the machine on the work piece at

up-right position as shown in fig.5. The

Cutter is not yet engaged with the

material at this stage, to prevent sudden

reaction.

o

Press the Trigger (C) and lower the Main

Handle slowly. When the Cutter contacts

the material, press the machine forward.

To stop operation,

o

Firmly hold the Main Handle (A) and the

Dead Handle (B).

o

Remove the tool from the workpiece

before stopping the cutter rotation., to

prevent sudden reaction.

o

Release the Trigger (C).

o

Visually confirm cutter stop before

putting the tool aside.

Caution for Safety Use of Air Supply

Air supply hose must be oil resistant and with

abrasion resistant exterior surface.

All connections must be in good condition and

properly installed. Do not use damaged, frayed

or deteriorated hose and fittings. Replace them

when necessary. Do not reform the hose and

fittings.

Always store the hose properly away from heat

sources and sunlight after use and inspect

before use. A hose failure can cause injury.

The use of a swivel coupling is recommended

so that rotating the tool will not distort or cause

disconnection of the supply hose.

Be sure to connect the hose to the machine

before switching on the air supply.

Cutter replacement

See Fig.6 page 3.

Disconnect air supply from the tool.

Make the machine face-up to see the cutter part.

Unfasten 4 pcs M6x25 Low head cap screw (A)

by an Allen head wrench (4mm Hex) .

Summary of Contents for FRC-200S-1

Page 4: ...Safety Information FRC 200S 1 5 Fig 5 6 Fig 6 cutter replacement...

Page 5: ......

Page 6: ...Safety Information FRC 200S 1 JA 6 EN Safety Information 10...

Page 9: ...FRC 200S 1 Safety Information...

Page 10: ...Safety Information FRC 200S 1 2 3 2 3 o D o E o E o 4 o D o A B o 5 o C o A B o o C o...

Page 12: ...Safety Information FRC 200S 1...