安全に関する情報

– Safety Information

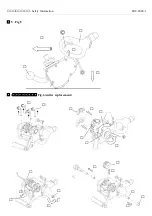

FRC-200S-1

Place the machine with the Cutter sideward. Turn

the Lock nut (B) counterclockwise to loosen.

Turn the Adjusting handle (C) counterclockwise

to lower the Guide arm (D) and remove the

Bearing case (E).

Pull out the Split pin (F) from the Spindle (G). Set

an Allen head wrench (6mm Hex) on the gear side

of the spindle and remove the spindle nut (H).

Remove the Bearing (I) and Spacer (J) from the

Spindle and pull out the spindle toward the gear to

remove the Cutter (K).

The Cutter mounting can be easily made in the

opposite order explained above.

When assembling Low head cap screw (A), make

sure to gently turn the spindle to ensure correct

alignment of the parts.

Caution for Safety Use of Cutter

Never use a Cutter which is cracked, damaged or

worn-out.

When the machine or cutter is stored in extremely

cold or hot places, make careful test runs.

If the machine is dropped, carefully check the

Cutter status before operation.

Air quality

It is necessary to remove water and foreign particles

from the air line. Dirty air will cause unexpected parts

wear and reduce operation efficiency.

Lubrication

Use an air line lubricator with Turbine Oil ISOVG32

or equivalent, adjusted to two (2) drops per minute.

Not lubricated air will cause unexpected parts wear and

reduce operation efficiency.

Lithium grease is recommended to be used for Ball

Bearing, Gears and Gear Casing.

Periodical Check and Repair

Whenever any unusual phenomena are felt or

noticed during operation, stop operation at once

for inspection and repair.

Periodical overhaul is recommended every 500

hour use or every 6 months.

Replacement of any parts must be done with Fuji

genuine parts to keep Fuji quality in performance

and durability.

Whenever the machine is inspected or repaired,

stop air supply and disconnect the air motor from

the air hose.

After the machine is reassembled, make sure that

all components are correctly assembled with bolts

and nuts tightened firmly.

Disposal

•

The disposal of this equipment must follow the

legislation of the respective country.

•

All damaged, badly worn or improperly

functioning devices

MUST BE TAKEN OUT

OF OPERATION.

•

The disposal of this equipment must follow the

legislation of the respective country.

•

Repair only by technical maintenance staff.

Maintenance instructions

•

Follow local country environmental

regulations for safe handling and disposal of

all components.

•

Maintenance and repair work must be carried out

by qualified personnel using only original spare

parts. Contact the manufacturer or your nearest

authorized dealer for advice on technical service

or if you require spare parts.

•

Always ensure that the machine is disconnected

from energy source to avoid accidental operation.

•

Disassemble and inspect the tool every three (3)

months if the tool is used every day. Replace

damaged or worn parts.

Useful information

Website

Log in to Fuji:

www.fujitools.com

.

You can find information concerning our

products, accessories, spare parts and published

matters on our website.

Country of origin

Japan

Summary of Contents for FRC-200S-1

Page 4: ...Safety Information FRC 200S 1 5 Fig 5 6 Fig 6 cutter replacement...

Page 5: ......

Page 6: ...Safety Information FRC 200S 1 JA 6 EN Safety Information 10...

Page 9: ...FRC 200S 1 Safety Information...

Page 10: ...Safety Information FRC 200S 1 2 3 2 3 o D o E o E o 4 o D o A B o 5 o C o A B o o C o...

Page 12: ...Safety Information FRC 200S 1...