54

3.5

Control Strip Processing

The processing solution performance should be evaluated by processing a control

strip, measuring the processed strip densities, and comparing them with the

reference strip densities.

3.5.1

Control Strip Preparation

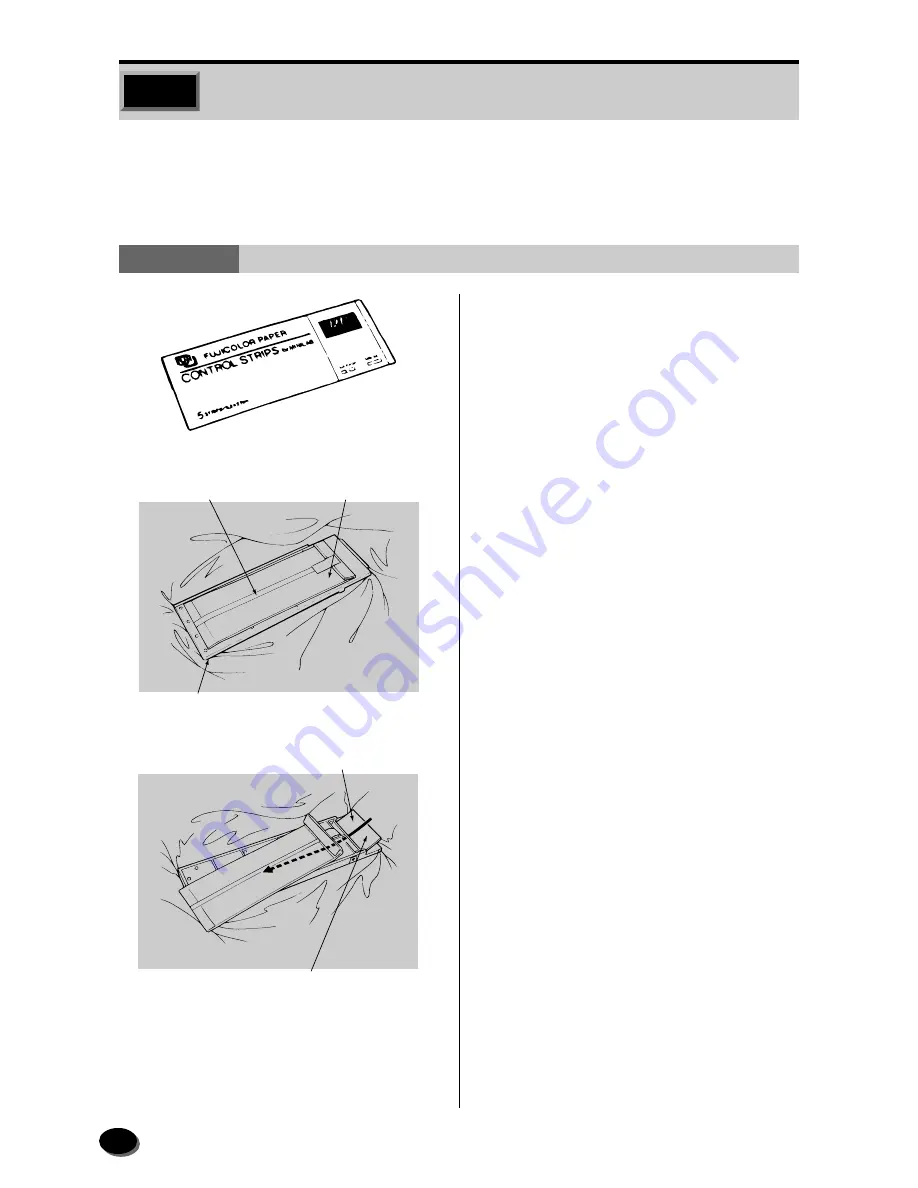

q

Take the control strip package out of the

freezer and let it sit for about one hour to

bring it to room temperature.

w

Take the inner bag out of the control strip

package and place it on the control strip

holder with the seam facing up, and then

put them both in a dark box. Close the dark

box cover.

e

Insert your hands into the sleeves of the

dark box, take one control strip out of the

inner bag, and insert it into the control strip

holder, as shown in the figure. Push it in

until it reaches the far end.

r

Fold over the open end of the inner bag to

prevent fogging of the unused control

strips.

t

Take the control strip holder and package

out of the dark box.

GD1774

Emulsion Surface

Upward

Control Strip

Seam

Control Strip Holder

Control Strip Inner Bag

EZ740

EZ1841

Summary of Contents for FRONTIER 390

Page 11: ...9 1 OPERATIONAL SAFETY AND USE CONDITIONS 9 GD1550 1 ...

Page 12: ...10 10 GD1559 1 3 2 Caution Label Locations on Printer Paper Processor ...

Page 13: ...11 1 OPERATIONAL SAFETY AND USE CONDITIONS 11 GD1560 ...

Page 19: ...17 1 OPERATIONAL SAFETY AND USE CONDITIONS 17 GD1550 2 ...

Page 165: ...169 10 LIST OF CONSUMABLES 10 1 Scanner 170 10 2 Printer Processor 171 ...

Page 168: ...173 11 INDEX 5 1 Index 174 5 2 Index of Basic Operating Instructions 176 ...