41S_Rev00

96

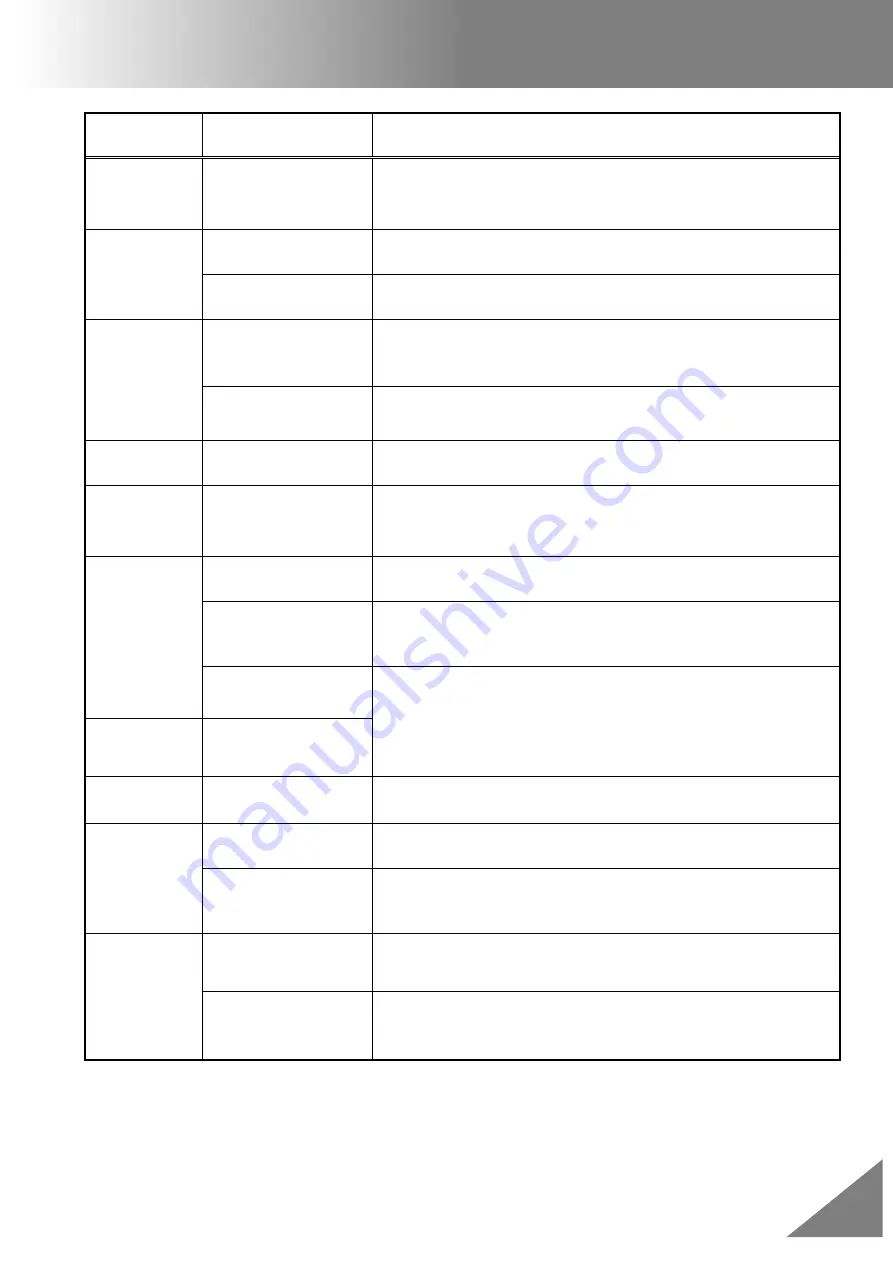

Error Message List

Error

Message

Reason

Solution

No Arc

Discharge

・

Arc Discharge did

not occur.

・

Assure the electrodes are in proper position.

・

Replace the electrodes.

・

Consult the authorized distributor.

Large

Cleave

Angle

・

Bad fiber

end-face.

・

Check the condition of the fiber cleaver. If the blade is

worn, rotate the blade to a new position.

・

[Cleave Limit] is

set too low.

・

Increase the [Cleave Limit] to an adequate limit.

Large

Fiber

Angle

・

Dust or dirt is on

the V-groove or

the clamp chip.

・

Clean the V-groove and clamp chip, and set the fibers

again. If the error occurs again, strip, clean and cleave

the fibers.

・

Bad fiber

end-face.

・

Check the condition of fiber cleaver. If the blade is worn,

rotate the blade to a new position.

Cleave

Shape NG

・

Bad fiber

end-face.

・

Check the condition of fiber cleaver. If the blade is worn,

rotate the blade to a new position.

Arc

Discharge

Delayed

・

Arc Discharge is

delayed

・

Assure the electrodes are in proper position.

・

Execute the [Stabilize Electrode] function.

・

Replace the electrodes.

Thin Fiber

・

Inadequate arc

power

・

Calibrate the arc power with the [Arc Calibration]

function.

・

Prefuse power or

time is set too

high

・

If using the Other mode, adjust or initialize [Prefuse

Power] or [Prefuse Time] settings. For normal splice

mode, the prefuse is fixed and cannot be adjusted.

・

Insufficient

[Overlap] setting

・

If using the Other mode, adjust or initialize [Overlap]

setting. For normal splice mode, the overlap is fixed and

cannot be adjusted.

・

Execute [Motor Calibration] function in the maintenance

menu to calibrate the stuff amount.

Fat Fiber

・

Too much

[Overlap] setting

Too Tapering

Fiber

・

Too much fiber

taper.

・

If using the taper splice function, the error message may

appear meaning the fiber is tapered too much.

Bubble

・

Bad fiber

end-face.

・

Check the condition of fiber cleaver. When the blade is

worn, rotate the blade.

・

Prefuse power or

time is set too low

・

If using the Other mode, adjust or initialize [Prefuse

Power] or [Prefuse Time] settings. For normal splice

mode, the prefuse is fixed and cannot be adjusted.

Large Dust

Burn

・

Bad fiber

end-face.

・

Check the condition of the fiber cleaver. If the blade is

worn, rotate the blade to a new position.

・

[Cleaning Arc]

time is too short

or “OFF.”

・

Dust still present after cleaning fiber or cleaning arc.

Clean fiber thoroughly or Increase [Cleaning Arc Time]