70S+A_Rev1

87

Maintenance

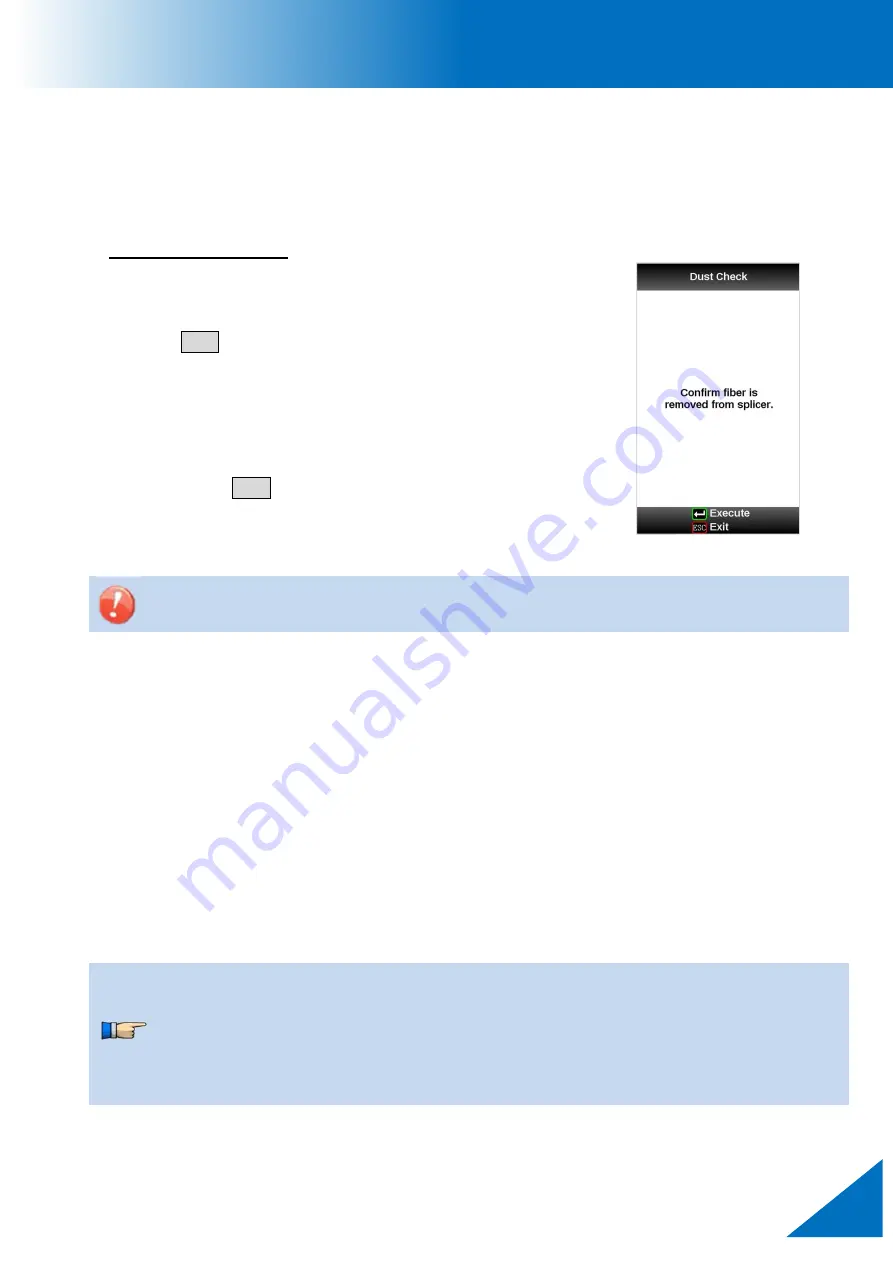

Dust Check

The splicer observes fibers through image processing. Dust or contaminants on the cameras

and lenses disturb normal observation of fibers and may result in improper splicing. This

function checks the optical path for the presence or absence of contaminants and judges

whether they cause trouble for fiber splicing.

Operation Procedure

1. Select the [Dust Check] in the [Maintenance Menu].

2. If fibers are set in the splicer, remove them and press

ENT key again. The splicer begins the dust check.

3. After observation, the location of contamination judged

as a potential problem blinks. If contamination is

discovered, clean the objective lenses and redo [Dust

Check] for cleaning instructions.

4. Press ESC key to finish dust check.

Arc Calibration

Atmospheric conditions such as temperature, humidity, and pressure are constantly

changing, which creates variability in the arc temperature. This splicer is equipped with

temperature sensor that is used in a constant feedback monitoring control system to

regulate the arc power at a constant level. Changes in arc power due to electrode wear and

glass adhesion cannot be corrected automatically. Also, the center position of arc discharge

sometimes shifts to the left or right. In this case, the fiber splicing position has to be shifted

in relation to the arc discharge center. It is necessary to perform an arc power calibration to

eliminate both of these issues.

In case you have cleaned the objective lenses and dirt or dust still remains, contact

the authorized distributor.

Arc calibration is performed automatically using [AUTO] mode only. So arc

calibration does not have to be performed when splicing in this mode.

Execute [Arc calibration] before using non-auto mode.

When performing the [Arc Calibration] function change the arc power “factor” value.

The factor value is used in the algorithm program for all splicing. The arc power value

will not change in the splice modes.