70S_Rev1

75

Maintenance

Diagnostic Test

The 70S has a built in diagnostic test feature that allows the operator to perform a simple one

step evaluation of splicer performance covering several different critical variables. Perform

this function in the event of splicer operation trouble.

Operation Procedure

1.

Select the [Diagnostic Test] in the [Maintenance Menu] and execute [Diagnostic

Test].The following checks will be made.

2. Upon completion of all checks and adjustments, a list of results is displayed. If the

dust check result is not good, clean the objective lenses. In the case that cleaning

cannot eliminate contamination, there is a possibility that the contamination may have

entered the inside of the optical path. Please contact the authorized distributor for

additional instructions.

The dust check and Motor Calibration functions exist as independent instructions in

[Maintenance Menu]. It is possible to execute them independently.

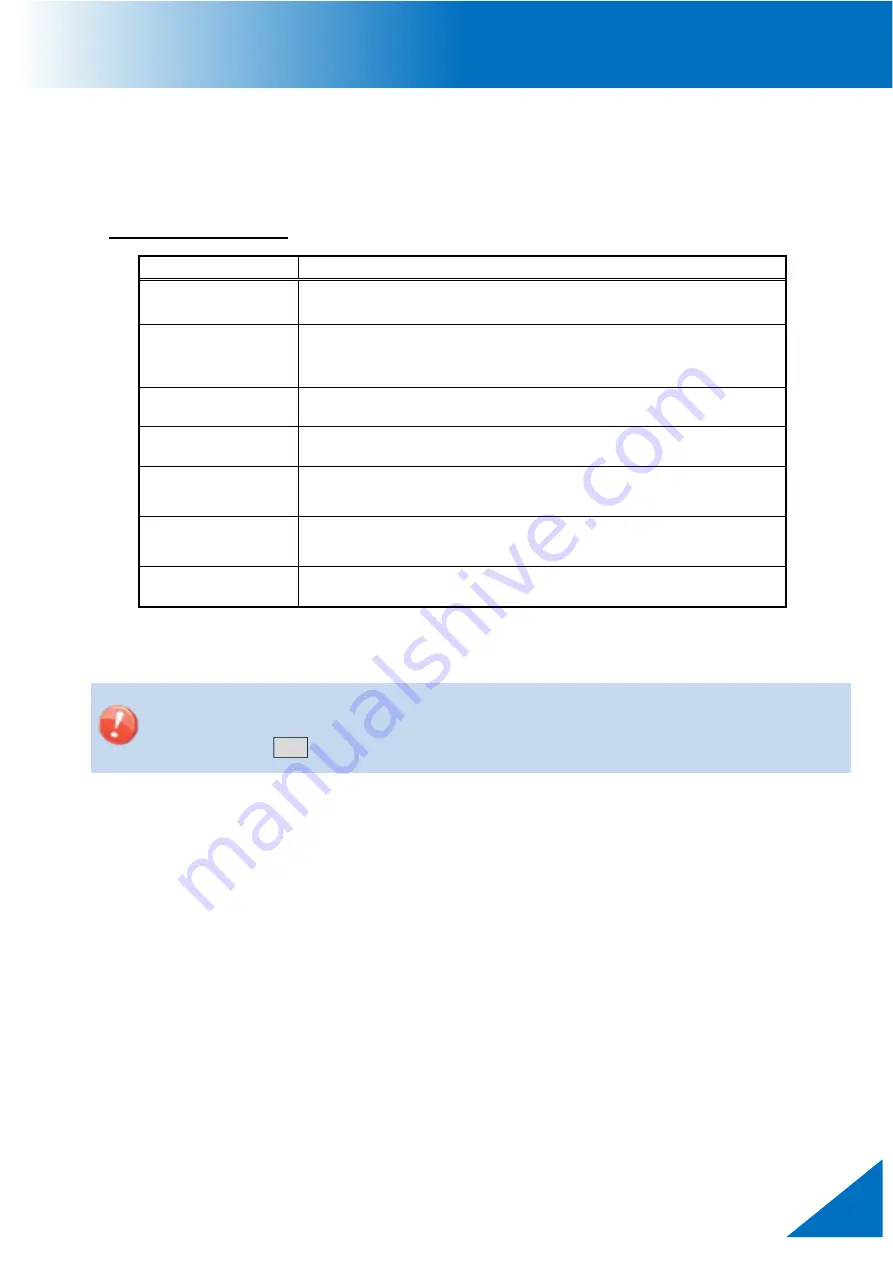

Check Item

Description

LED Check

Measures and adjusts the brightness of the illumination

LED.

Dust Check

Checks the optical path for dust or dirt and judges whether

they disturb fiber observation. If contamination exists, this

function indicates the location.

Motor Check

Check the Motor Limit Sensor.

Motor Calibration

Check the Motor Calibration.

Arc Calibration

Automatically calibrates the arc power factor and fiber

splicing position.

I/O Port Check

Checks for normal operation of the input and output

terminals of the internal circuit.

Memory Check

Checks the memory of the internal circuit.

Before the start of the test, remove the fibers from the splicer.

When the Motor check is completed, prepare and load the fibers into the splicer and

press ENT key.