70S_Rev1

86

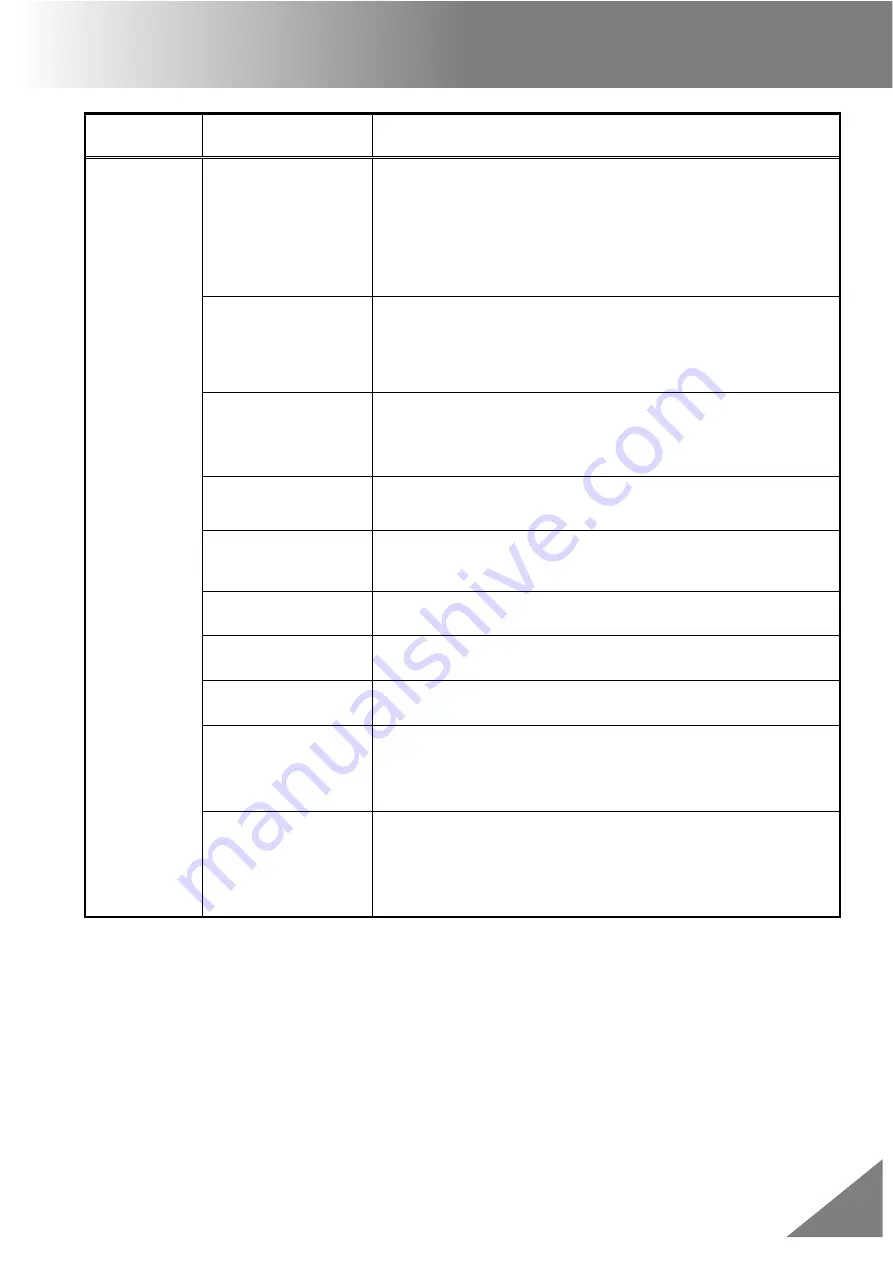

Error Message List

Error

Message

Reason

Solution

High

Estimated

Loss

・

Insufficient fiber

cleaning.

・

Dust or dirt on the fiber surface results in bad splice loss

and low tensile strength.

・

Clean the fiber surface sufficiently.

・

Do not clean the fiber after cleaving to prevent dust on

the fiber end-face.

・

Avoid any contact with the fiber end-face.

・

Bad fiber

end-face.

・

Check the condition of fiber cleaver. If the blade is worn,

rotate the blade to a new position.

・

Confirm the [Cleave Limit] setting. 2.0° or less is

recommended.

・

Dust or dirt is on

the V-groove or

the clamp chip.

・

Dust or dirt on the V-groove or clamp chip causes poor

fiber movement during fiber stuffing. Clean them

periodically.

・

Dust or dirt is on

the lens

・

Execute the [Dust Check]. If dust or dirt exists, clean the

lenses.

・

Bad electrode

condition.

・

Replace the electrodes if they appear worn (rounded tip

shape), dirty or bent.

・

Inadequate arc

power.

・

Calibrate the arc power with the [Arc Calibration]

function.

・

Using unsuitable

splice mode

・

Select a suitable splice mode for the fibers to be spliced.

・

[Loss Limit] is set

too low.

・

Increase [Loss Limit] to an adequate limit.

・

Inadequate arc

parameters in

other splice

modes

・

Confirm the arc parameters are adequate to splice the

fibers.

・

Inadequate

estimating

parameters in

Other mode

・

Confirm the estimating parameters are adequate to

estimate the loss. The MFD mismatch function does not

work for certain types of specialty fibers. In these cases,

set the [MFD Mismatch] to “OFF”.