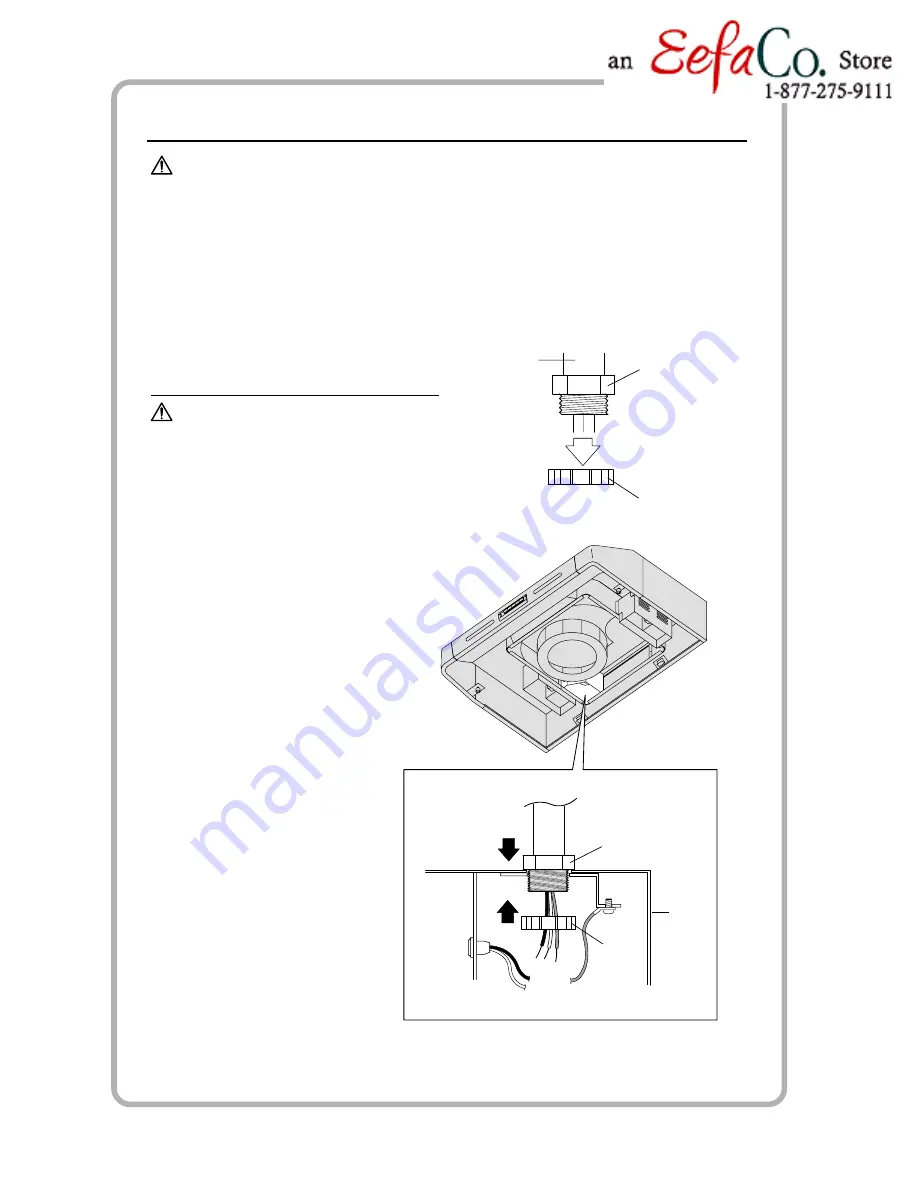

Conduit

Nut

Range

Hood

3. CONNECTING POWER SUPPLY WIRES

WARNING

: • Electrical wiring should be done by a qualified person(s) in

accordance with all-applicable codes and standards,

including fire-rated construction. An unqualified person

doing the work could result in fire, electric shock or injury.

• This range hood uses 120V AC. Do not connect to another

voltage since fire, electric shock or damage could result.

1

Remove the nut from the conduit

connector at the end of power wiring.

WARNING

: Be sure to switch

power OFF at service panel

before wiring.

2

Connect the conduit through the

connecting hole of the body using the

nut previously removed.

Conduit

Nut

Power

Wiring

12